PET and PVC are two common types of plastics with distinct properties and uses. PET is lightweight, recyclable, and commonly used for beverage bottles due to its clarity and strength, whereas PVC is more durable and resistant to chemicals, often utilized in construction materials and piping. Choosing between PET and PVC depends on the required flexibility, environmental impact, and application needs.

Table of Comparison

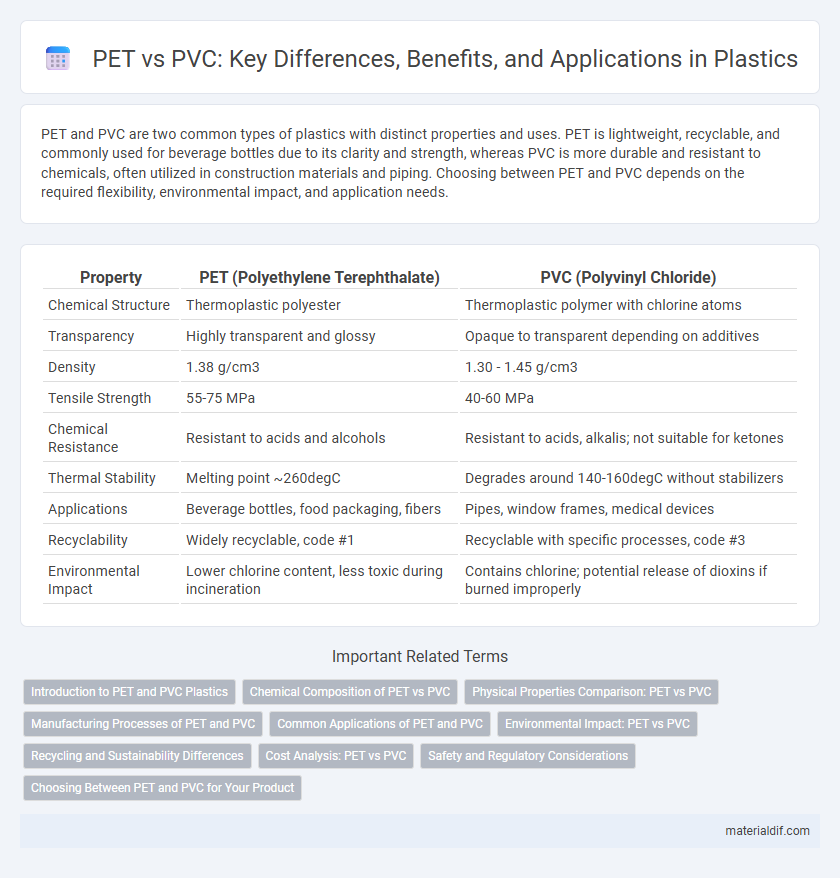

| Property | PET (Polyethylene Terephthalate) | PVC (Polyvinyl Chloride) |

|---|---|---|

| Chemical Structure | Thermoplastic polyester | Thermoplastic polymer with chlorine atoms |

| Transparency | Highly transparent and glossy | Opaque to transparent depending on additives |

| Density | 1.38 g/cm3 | 1.30 - 1.45 g/cm3 |

| Tensile Strength | 55-75 MPa | 40-60 MPa |

| Chemical Resistance | Resistant to acids and alcohols | Resistant to acids, alkalis; not suitable for ketones |

| Thermal Stability | Melting point ~260degC | Degrades around 140-160degC without stabilizers |

| Applications | Beverage bottles, food packaging, fibers | Pipes, window frames, medical devices |

| Recyclability | Widely recyclable, code #1 | Recyclable with specific processes, code #3 |

| Environmental Impact | Lower chlorine content, less toxic during incineration | Contains chlorine; potential release of dioxins if burned improperly |

Introduction to PET and PVC Plastics

Polyethylene terephthalate (PET) and polyvinyl chloride (PVC) are two widely used plastics with distinct properties and applications. PET is a lightweight, transparent polymer commonly used in beverage bottles, food packaging, and textiles due to its excellent strength, chemical resistance, and recyclability. PVC is a versatile, durable plastic often found in construction materials, pipes, and electrical insulation because of its flame resistance and adaptability through plasticizers.

Chemical Composition of PET vs PVC

Polyethylene terephthalate (PET) consists of repeating units of ethylene terephthalate, formed by the polymerization of ethylene glycol and terephthalic acid, creating a structure characterized by ester linkages. Polyvinyl chloride (PVC) is composed of repeating vinyl chloride monomers, featuring a carbon-carbon backbone with chlorine atoms attached to every other carbon, imparting its unique chemical and physical properties. The absence of chlorine in PET results in higher chemical resistance and different thermal stability compared to PVC, influencing their respective applications in packaging and construction.

Physical Properties Comparison: PET vs PVC

PET (Polyethylene Terephthalate) offers higher tensile strength and better impact resistance compared to PVC (Polyvinyl Chloride), making it more suitable for applications requiring durability. PVC exhibits greater flexibility and superior chemical resistance, especially against acids and alkalis, but tends to be heavier and less transparent than PET. The thermal stability of PET is generally higher, with a melting point around 260degC, whereas PVC decomposes before melting, limiting its use in high-temperature environments.

Manufacturing Processes of PET and PVC

PET (polyethylene terephthalate) manufacturing involves a polycondensation reaction between terephthalic acid and ethylene glycol, followed by processes like melt polymerization and solid-state polymerization to achieve high molecular weight. PVC (polyvinyl chloride) production relies on polymerizing vinyl chloride monomer through suspension, emulsion, or bulk polymerization techniques, with suspension polymerization being the most common due to producing uniform particle sizes and better process control. The distinct manufacturing pathways influence thermal properties, mechanical strength, and environmental impact of PET and PVC materials.

Common Applications of PET and PVC

PET (Polyethylene Terephthalate) is widely used in beverage bottles, food packaging, and synthetic fibers due to its excellent strength, transparency, and recyclability. PVC (Polyvinyl Chloride) dominates in construction materials, medical devices, and electrical cable insulation because of its durability, chemical resistance, and versatility. The choice between PET and PVC depends on the required application properties such as flexibility, clarity, and environmental impact.

Environmental Impact: PET vs PVC

PET (polyethylene terephthalate) has a significantly lower environmental impact compared to PVC (polyvinyl chloride) due to its higher recyclability and lower release of toxic chemicals during production and disposal. PET is widely accepted in recycling programs and breaks down more efficiently, reducing landfill accumulation and marine pollution risks. PVC production and incineration release hazardous substances such as dioxins and phthalates, posing greater environmental and health hazards.

Recycling and Sustainability Differences

PET (Polyethylene Terephthalate) is highly recyclable and widely accepted in curbside recycling programs, promoting a circular economy with lower environmental impact. PVC (Polyvinyl Chloride) presents challenges in recycling due to its chlorine content, which can release harmful toxins during processing and limits its sustainability. PET's greater recyclability and lower toxicity make it a preferred choice for eco-friendly packaging and sustainable material solutions.

Cost Analysis: PET vs PVC

PET (polyethylene terephthalate) offers a lower production cost compared to PVC (polyvinyl chloride) due to its efficient recycling process and lower raw material expenses. PVC requires more energy-intensive manufacturing and involves additives that elevate overall costs, impacting large-scale production budgets. Cost analysis reveals PET as a more economically sustainable option for packaging and consumer goods industries.

Safety and Regulatory Considerations

PET (polyethylene terephthalate) is widely recognized for its safety in food and beverage packaging due to its non-toxic, BPA-free composition and strong regulatory approval from agencies like the FDA and EFSA. PVC (polyvinyl chloride), however, raises safety concerns because it can release harmful chemicals such as phthalates and dioxins during production, use, and disposal, leading to stricter restrictions and regulatory scrutiny in many regions. Regulatory bodies increasingly favor PET over PVC for consumer products, emphasizing PET's recyclability and lower health risks in compliance with global safety standards.

Choosing Between PET and PVC for Your Product

PET offers superior clarity, chemical resistance, and recyclability compared to PVC, making it ideal for food and beverage packaging. PVC provides excellent durability, flexibility, and cost-effectiveness, often used in construction and medical applications. Choosing between PET and PVC depends on factors like product safety, environmental impact, and specific functional requirements.

PET vs PVC Infographic

materialdif.com

materialdif.com