High-Density Polyethylene (HDPE) features a linear polymer structure with minimal branching, resulting in higher tensile strength and rigidity compared to Low-Density Polyethylene (LDPE), which has a branched polymer chain that provides greater flexibility and impact resistance. HDPE is commonly used for durable goods like piping, containers, and plastic bottles, while LDPE is preferred for applications requiring pliability, such as plastic bags and film wraps. The difference in density also impacts their melting points, with HDPE melting at a higher temperature, making it suitable for more heat-resistant products.

Table of Comparison

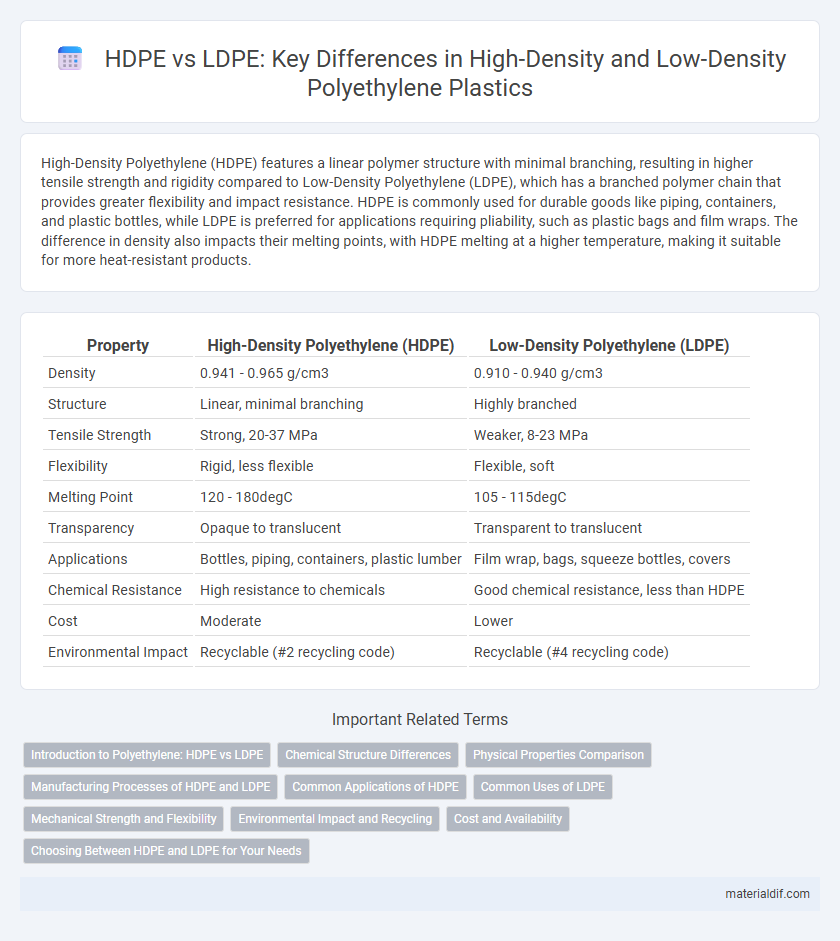

| Property | High-Density Polyethylene (HDPE) | Low-Density Polyethylene (LDPE) |

|---|---|---|

| Density | 0.941 - 0.965 g/cm3 | 0.910 - 0.940 g/cm3 |

| Structure | Linear, minimal branching | Highly branched |

| Tensile Strength | Strong, 20-37 MPa | Weaker, 8-23 MPa |

| Flexibility | Rigid, less flexible | Flexible, soft |

| Melting Point | 120 - 180degC | 105 - 115degC |

| Transparency | Opaque to translucent | Transparent to translucent |

| Applications | Bottles, piping, containers, plastic lumber | Film wrap, bags, squeeze bottles, covers |

| Chemical Resistance | High resistance to chemicals | Good chemical resistance, less than HDPE |

| Cost | Moderate | Lower |

| Environmental Impact | Recyclable (#2 recycling code) | Recyclable (#4 recycling code) |

Introduction to Polyethylene: HDPE vs LDPE

High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE) are two primary types of polyethylene distinguished by their density and branching structure. HDPE exhibits a linear structure with minimal branching, resulting in higher tensile strength, rigidity, and chemical resistance, making it ideal for products like piping, containers, and industrial applications. In contrast, LDPE has a highly branched structure that imparts flexibility, lower density, and impact resistance, commonly used in film wraps, bags, and squeezable bottles.

Chemical Structure Differences

High-Density Polyethylene (HDPE) features a linear polymer structure with minimal branching, resulting in tightly packed molecules and higher density. Low-Density Polyethylene (LDPE) contains significant long and short chain branching, causing a less compact molecular arrangement and lower density. The structural variations influence their melting points, tensile strength, and chemical resistance properties.

Physical Properties Comparison

High-Density Polyethylene (HDPE) exhibits a denser molecular structure with a density range of 0.941 to 0.965 g/cm3, resulting in higher tensile strength and rigidity compared to Low-Density Polyethylene (LDPE), which has a density of 0.910 to 0.940 g/cm3. HDPE features a crystalline structure that provides improved resistance to impact and chemical corrosion, while LDPE's branched chains create a more flexible and softer material with greater elongation at break. The melting point of HDPE ranges from 120degC to 180degC, significantly higher than LDPE's 105degC to 115degC, affecting their suitability for different thermal applications.

Manufacturing Processes of HDPE and LDPE

High-Density Polyethylene (HDPE) is manufactured through a high-pressure polymerization process using Ziegler-Natta or metallocene catalysts that produce linear chains with minimal branching, resulting in a dense and strong polymer structure. Low-Density Polyethylene (LDPE) is produced via free radical polymerization at extremely high pressures and temperatures, which leads to significant chain branching and a more flexible, less crystalline material. The differing polymerization techniques directly impact the molecular architecture and physical properties of HDPE and LDPE, tailoring them for distinct industrial applications.

Common Applications of HDPE

High-Density Polyethylene (HDPE) is widely used in the production of plastic bottles, corrosion-resistant piping, and plastic lumber due to its high strength-to-density ratio and chemical resistance. Its applications extend to food storage containers, grocery bags, and geomembranes for landfill liners, benefiting from its rigidity and resistance to impact. HDPE's versatility in industrial, commercial, and consumer products distinguishes it from Low-Density Polyethylene (LDPE), which is preferred in flexible applications like plastic wraps and squeeze bottles.

Common Uses of LDPE

Low-Density Polyethylene (LDPE) is widely used in packaging applications such as plastic bags, film wrap, and squeeze bottles due to its flexibility and moisture resistance. It is also common in manufacturing containers, lids, and tubing where impact resistance and clarity are important. Compared to High-Density Polyethylene (HDPE), LDPE offers greater elasticity but lower tensile strength, making it ideal for products requiring softness and pliability.

Mechanical Strength and Flexibility

High-Density Polyethylene (HDPE) exhibits superior mechanical strength due to its tightly packed molecular structure, making it highly resistant to impact and stress. Low-Density Polyethylene (LDPE) offers greater flexibility and elasticity, attributed to its branched polymer chains that allow for easier deformation under load. HDPE is typically used in applications requiring rigidity and durability, whereas LDPE excels in products needing pliability and resilience.

Environmental Impact and Recycling

High-Density Polyethylene (HDPE) features a more compact molecular structure, making it denser and easier to recycle compared to Low-Density Polyethylene (LDPE), which has a branched structure leading to lower density and more complex recycling processes. HDPE bottles and containers are widely accepted in curbside recycling programs, contributing to lower environmental impact through efficient material recovery and reuse. LDPE, often used in flexible films and bags, faces higher rates of landfill disposal due to limited recycling facilities and higher contamination risk, resulting in greater environmental challenges.

Cost and Availability

High-Density Polyethylene (HDPE) generally offers a lower cost per pound compared to Low-Density Polyethylene (LDPE), making it a more economical choice for large-scale applications. HDPE's widespread production results in higher availability across global markets, whereas LDPE, often used for flexible films and packaging, has a more limited supply chain. Pricing volatility affects LDPE more significantly due to its specialized usage and production processes.

Choosing Between HDPE and LDPE for Your Needs

High-Density Polyethylene (HDPE) offers superior strength and chemical resistance, making it ideal for heavy-duty containers, outdoor piping, and durable packaging. Low-Density Polyethylene (LDPE) provides greater flexibility and transparency, suited for applications like plastic bags, film wraps, and squeeze bottles. Selecting between HDPE and LDPE depends on factors such as desired rigidity, environmental exposure, and cost-efficiency for specific industrial or consumer uses.

High-Density Polyethylene (HDPE) vs Low-Density Polyethylene (LDPE) Infographic

materialdif.com

materialdif.com