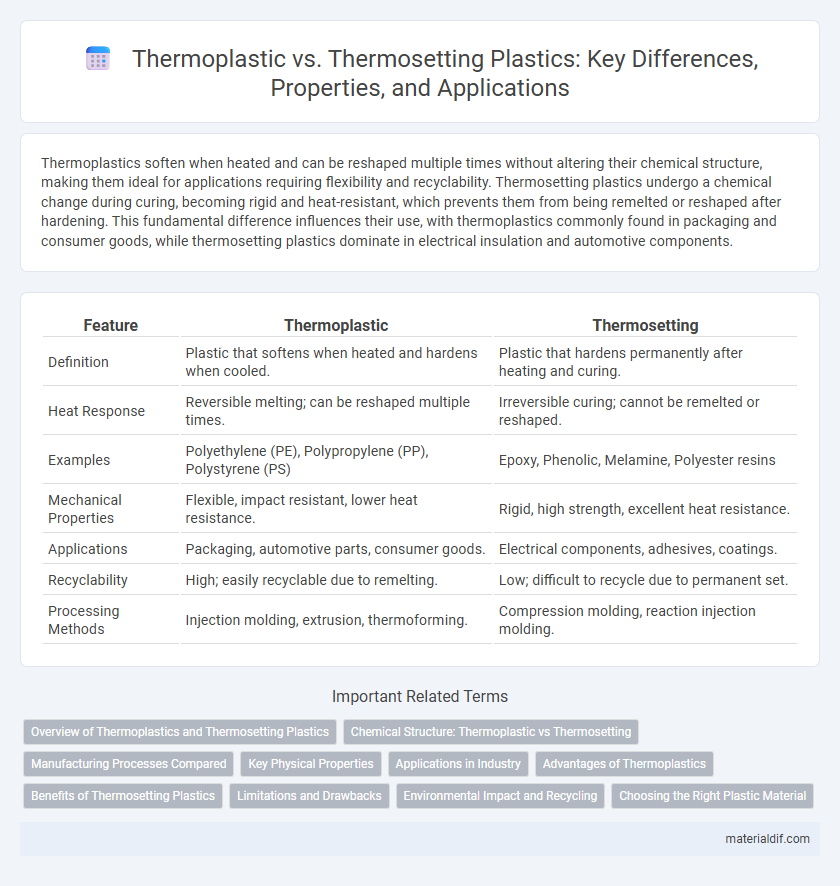

Thermoplastics soften when heated and can be reshaped multiple times without altering their chemical structure, making them ideal for applications requiring flexibility and recyclability. Thermosetting plastics undergo a chemical change during curing, becoming rigid and heat-resistant, which prevents them from being remelted or reshaped after hardening. This fundamental difference influences their use, with thermoplastics commonly found in packaging and consumer goods, while thermosetting plastics dominate in electrical insulation and automotive components.

Table of Comparison

| Feature | Thermoplastic | Thermosetting |

|---|---|---|

| Definition | Plastic that softens when heated and hardens when cooled. | Plastic that hardens permanently after heating and curing. |

| Heat Response | Reversible melting; can be reshaped multiple times. | Irreversible curing; cannot be remelted or reshaped. |

| Examples | Polyethylene (PE), Polypropylene (PP), Polystyrene (PS) | Epoxy, Phenolic, Melamine, Polyester resins |

| Mechanical Properties | Flexible, impact resistant, lower heat resistance. | Rigid, high strength, excellent heat resistance. |

| Applications | Packaging, automotive parts, consumer goods. | Electrical components, adhesives, coatings. |

| Recyclability | High; easily recyclable due to remelting. | Low; difficult to recycle due to permanent set. |

| Processing Methods | Injection molding, extrusion, thermoforming. | Compression molding, reaction injection molding. |

Overview of Thermoplastics and Thermosetting Plastics

Thermoplastics are polymers that become soft and moldable upon heating and solidify upon cooling, allowing multiple recycling and reshaping cycles without significant chemical change. Thermosetting plastics, once cured through a chemical reaction, form irreversible cross-linked structures that provide superior heat resistance, mechanical strength, and dimensional stability but cannot be remelted or reshaped. Common thermoplastics include polyethylene, polypropylene, and polystyrene, while thermosets include epoxy, phenolic, and melamine resins, each serving distinct industrial applications based on their thermal and mechanical properties.

Chemical Structure: Thermoplastic vs Thermosetting

Thermoplastics consist of linear or branched polymer chains without cross-linking, allowing them to soften and melt upon heating. Thermosetting plastics have heavily cross-linked polymer networks, creating a rigid, three-dimensional structure that prevents melting after curing. This fundamental difference in chemical structure dictates their thermal behavior and recyclability.

Manufacturing Processes Compared

Thermoplastics undergo manufacturing processes such as injection molding, extrusion, and blow molding, allowing repeated melting and reshaping due to their reversible molecular structure. Thermosetting plastics are formed using processes like compression molding, transfer molding, and casting, which involve irreversible cross-linking that hardens the material permanently. The manufacturing of thermoplastics is generally faster and more versatile while thermosetting plastics offer higher heat resistance and structural integrity after curing.

Key Physical Properties

Thermoplastics exhibit high flexibility and can be remelted multiple times without significant chemical change, characterized by their ability to soften when heated and harden upon cooling due to physical intermolecular forces. Thermosetting plastics, such as epoxy and phenolic resins, form irreversible chemical bonds during curing, resulting in rigid, heat-resistant materials that do not melt upon reheating. Key physical properties differentiating the two include thermoplastics' recyclability and impact resistance versus thermosets' superior dimensional stability, thermal resistance, and higher mechanical strength.

Applications in Industry

Thermoplastics, known for their recyclability and flexibility, dominate applications in automotive parts, packaging, and consumer goods due to their ease of molding and reshaping. Thermosetting plastics, prized for their heat resistance and dimensional stability, are widely used in electrical insulators, adhesives, and composite materials for aerospace and electronics industries. The choice between thermoplastics and thermosetting plastics in industry depends heavily on the mechanical requirements and thermal performance needed for specific applications.

Advantages of Thermoplastics

Thermoplastics offer significant advantages such as recyclability, ease of molding, and the ability to be reshaped multiple times without degradation. Their versatility in processing methods like injection molding and extrusion enables efficient mass production and design flexibility. Additionally, thermoplastics exhibit excellent impact resistance and chemical stability, making them ideal for a wide range of industrial and consumer applications.

Benefits of Thermosetting Plastics

Thermosetting plastics offer superior heat resistance and mechanical strength compared to thermoplastics, making them ideal for high-temperature applications in automotive and aerospace industries. Their chemical stability and rigidity reduce deformation under stress, enhancing durability in electrical insulation and cookware. These properties contribute to longer service life and improved safety in demanding environments.

Limitations and Drawbacks

Thermoplastics often exhibit lower heat resistance and mechanical strength compared to thermosetting plastics, limiting their use in high-temperature or structural applications. Thermosetting plastics, while offering superior thermal stability and rigidity, suffer from brittleness and are generally non-recyclable due to their irreversible curing process. Both materials present challenges in processing and environmental impact, with thermoplastics prone to deformation under stress and thermosets generating hazardous waste.

Environmental Impact and Recycling

Thermoplastics, made from polymer chains that soften when heated, allow for efficient recycling through melting and remolding, reducing plastic waste and environmental pollution. Thermosetting plastics, with cross-linked polymer structures, cannot be reshaped once set, leading to more landfill accumulation and challenges in recycling processes. The environmental impact of thermosetting plastics includes higher resource consumption and difficulty in recycling, whereas thermoplastics offer a more sustainable alternative due to their recyclability and lower carbon footprint.

Choosing the Right Plastic Material

Thermoplastics offer versatility with their ability to be reshaped multiple times, making them ideal for applications requiring recyclability and flexibility, such as packaging and automotive parts. Thermosetting plastics provide superior heat resistance and structural integrity after curing, which suits high-stress environments like electrical insulators and aerospace components. Selecting the right plastic material depends on factors like thermal stability, mechanical strength, and end-use durability requirements.

Thermoplastic vs Thermosetting Infographic

materialdif.com

materialdif.com