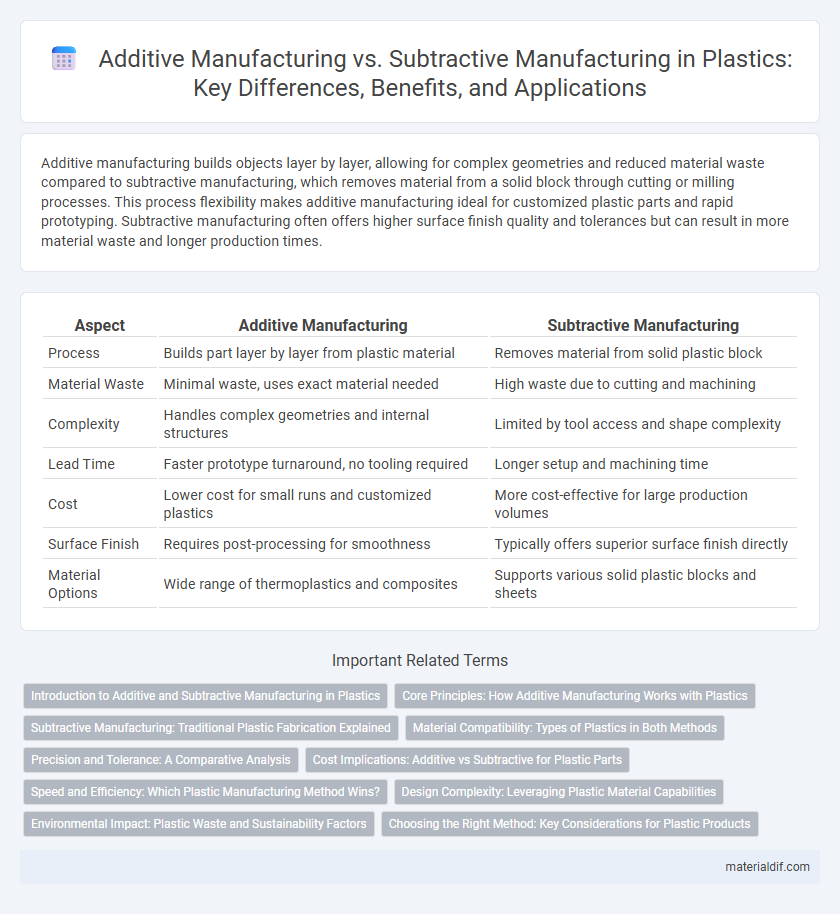

Additive manufacturing builds objects layer by layer, allowing for complex geometries and reduced material waste compared to subtractive manufacturing, which removes material from a solid block through cutting or milling processes. This process flexibility makes additive manufacturing ideal for customized plastic parts and rapid prototyping. Subtractive manufacturing often offers higher surface finish quality and tolerances but can result in more material waste and longer production times.

Table of Comparison

| Aspect | Additive Manufacturing | Subtractive Manufacturing |

|---|---|---|

| Process | Builds part layer by layer from plastic material | Removes material from solid plastic block |

| Material Waste | Minimal waste, uses exact material needed | High waste due to cutting and machining |

| Complexity | Handles complex geometries and internal structures | Limited by tool access and shape complexity |

| Lead Time | Faster prototype turnaround, no tooling required | Longer setup and machining time |

| Cost | Lower cost for small runs and customized plastics | More cost-effective for large production volumes |

| Surface Finish | Requires post-processing for smoothness | Typically offers superior surface finish directly |

| Material Options | Wide range of thermoplastics and composites | Supports various solid plastic blocks and sheets |

Introduction to Additive and Subtractive Manufacturing in Plastics

Additive manufacturing in plastics builds parts layer by layer using materials such as thermoplastics and photopolymers, enabling complex geometries and minimal waste. Subtractive manufacturing, conversely, involves cutting away material from plastic blocks or sheets through processes like CNC machining or laser cutting, which offers high precision but generates more scrap. Both methods serve distinct roles in plastic fabrication, with additive manufacturing excelling in rapid prototyping and customization, while subtractive manufacturing is preferred for high-tolerance, consistent production runs.

Core Principles: How Additive Manufacturing Works with Plastics

Additive manufacturing with plastics builds objects layer by layer using materials such as thermoplastics, photopolymers, or composites, precisely depositing molten or cured plastic based on 3D digital models. This process contrasts with subtractive manufacturing, which removes material from solid plastic blocks through machining or cutting. Key technologies in plastic additive manufacturing include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), each enabling complex geometries and material efficiency unattainable by traditional subtractive methods.

Subtractive Manufacturing: Traditional Plastic Fabrication Explained

Subtractive manufacturing in traditional plastic fabrication involves removing material from a solid plastic block using CNC machines, routers, or milling tools to achieve precise shapes and dimensions. This method offers high accuracy and smooth surface finishes, making it ideal for prototypes and low-volume production runs where dimensional tolerance is critical. Despite slower material use compared to additive manufacturing, subtractive processes excel in producing durable, high-strength plastic parts from engineering-grade polymers.

Material Compatibility: Types of Plastics in Both Methods

Additive manufacturing supports a wide range of thermoplastics such as ABS, PLA, PETG, and Nylon, enabling complex geometries and lightweight designs. Subtractive manufacturing works effectively with high-performance plastics like PEEK, PTFE, and polycarbonate, offering precise dimensional tolerances and superior surface finishes. Compatibility considerations include the thermal and mechanical properties of plastics, where additive methods favor materials with lower melting points and subtractive methods excel with rigid, chemically resistant polymers.

Precision and Tolerance: A Comparative Analysis

Additive manufacturing in plastics enables high precision with complex geometries and tight tolerances by depositing material layer by layer, minimizing waste and achieving fine detail. Subtractive manufacturing offers exceptional surface finishes and controlled dimensional accuracy by removing material from solid blocks, ensuring consistent tolerance in large-scale production. Comparing both, additive manufacturing excels in customization and intricate design precision, while subtractive methods provide superior repeatability and machining tolerance in traditional plastic part fabrication.

Cost Implications: Additive vs Subtractive for Plastic Parts

Additive manufacturing significantly reduces material waste, lowering overall costs compared to subtractive manufacturing, which often requires expensive raw plastic blocks and generates more scrap. The initial investment for additive equipment can be higher, but the ability to produce complex geometries without tooling expenses offers substantial cost savings for low to medium volume production runs. Subtractive processes benefit from faster production rates in high-volume scenarios, yet the cumulative material and labor costs generally make additive manufacturing more economical for customized plastic parts.

Speed and Efficiency: Which Plastic Manufacturing Method Wins?

Additive manufacturing in plastics offers faster prototyping and reduced material waste compared to subtractive methods, enhancing overall efficiency for complex designs. Subtractive manufacturing, while slower due to machining processes, provides high precision and smooth surface finishes ideal for large production runs. Speed and efficiency depend on project scale and complexity, with additive manufacturing excelling in rapid iterations and subtractive manufacturing dominating in mass production.

Design Complexity: Leveraging Plastic Material Capabilities

Additive manufacturing enables intricate plastic designs by building layers with high precision, maximizing material properties and minimizing waste. Subtractive manufacturing, while effective for simpler geometries, often struggles with complex plastic components due to material removal limitations and increased risk of defects. Leveraging plastic's versatility, additive processes unlock advanced design complexity that traditional subtractive methods cannot efficiently achieve.

Environmental Impact: Plastic Waste and Sustainability Factors

Additive manufacturing significantly reduces plastic waste by using only the material necessary to build parts, minimizing excess and scraps common in subtractive manufacturing. Subtractive processes often generate large quantities of plastic offcuts, which contribute to environmental pollution and landfill overflow. Additive methods promote sustainability by enabling precise material usage, recycling of unused powders, and supporting design optimization to create lightweight, durable plastic components with a lower carbon footprint.

Choosing the Right Method: Key Considerations for Plastic Products

Choosing the right manufacturing method for plastic products depends on factors like design complexity, production volume, and material waste management. Additive manufacturing excels in producing intricate geometries with minimal material waste, ideal for prototypes and low-volume runs. Subtractive manufacturing offers faster production for high-volume, simple shapes but generates more material waste, influencing cost and environmental impact.

Additive Manufacturing vs Subtractive Manufacturing Infographic

materialdif.com

materialdif.com