Thermoset plastics undergo a chemical curing process that creates a rigid, infusible structure, making them highly resistant to heat and deformation. Thermoplastics can be repeatedly melted and reshaped, offering versatility and ease of manufacturing but less thermal stability compared to thermosets. Choosing between thermoset and thermoplastic depends on the application's requirements for durability, heat resistance, and recyclability.

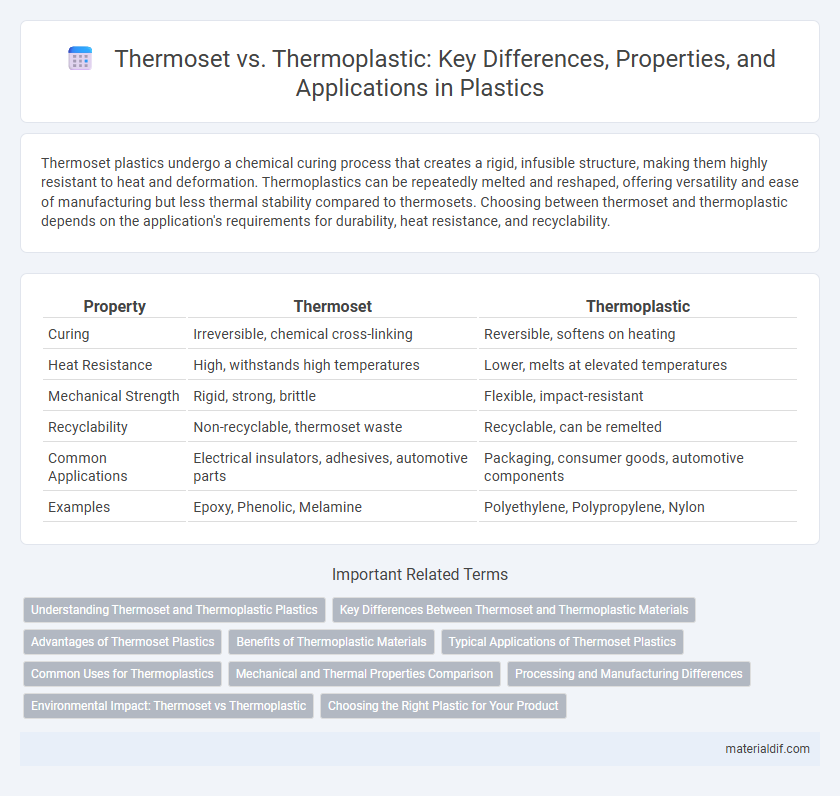

Table of Comparison

| Property | Thermoset | Thermoplastic |

|---|---|---|

| Curing | Irreversible, chemical cross-linking | Reversible, softens on heating |

| Heat Resistance | High, withstands high temperatures | Lower, melts at elevated temperatures |

| Mechanical Strength | Rigid, strong, brittle | Flexible, impact-resistant |

| Recyclability | Non-recyclable, thermoset waste | Recyclable, can be remelted |

| Common Applications | Electrical insulators, adhesives, automotive parts | Packaging, consumer goods, automotive components |

| Examples | Epoxy, Phenolic, Melamine | Polyethylene, Polypropylene, Nylon |

Understanding Thermoset and Thermoplastic Plastics

Thermoset plastics undergo a chemical curing process that creates a rigid, three-dimensional network, making them heat-resistant and ideal for high-strength applications such as electrical insulation and automotive components. Thermoplastics consist of linear or branched polymer chains that soften when heated and harden upon cooling, allowing for easy reshaping and recycling, commonly used in packaging, consumer goods, and medical devices. Understanding the fundamental differences in molecular structure and thermal behavior helps in selecting the appropriate plastic type for specific industrial applications.

Key Differences Between Thermoset and Thermoplastic Materials

Thermoset plastics undergo a chemical change during curing, resulting in a rigid, heat-resistant structure that cannot be remelted, whereas thermoplastics consist of linear or branched polymers that soften upon heating and can be reshaped repeatedly. Thermosets provide superior thermal stability, mechanical strength, and chemical resistance, making them ideal for durable components in automotive and aerospace industries. Thermoplastics offer ease of processing, recyclability, and impact resistance, commonly used for packaging, consumer goods, and flexible components.

Advantages of Thermoset Plastics

Thermoset plastics offer superior mechanical strength and thermal stability, making them ideal for high-temperature applications such as electrical insulators and automotive parts. Their cross-linked polymer structure provides excellent chemical resistance and dimensional stability, preventing deformation under heavy stress or heat. These properties ensure long-lasting performance in demanding environments where thermoplastics may soften or deform.

Benefits of Thermoplastic Materials

Thermoplastic materials offer high recyclability and ease of processing, making them environmentally advantageous compared to thermosets. Their ability to be repeatedly melted and reshaped allows for cost-effective manufacturing and design flexibility. Common applications include automotive parts, packaging, and consumer goods where durability and adaptability are essential.

Typical Applications of Thermoset Plastics

Thermoset plastics are widely used in electrical insulation, automotive components, and aerospace parts due to their high heat resistance and dimensional stability. Common applications include circuit boards, engine parts, and adhesives, where durability and resistance to deformation are critical. These materials maintain structural integrity under stress and high temperatures, making them ideal for industrial and structural uses.

Common Uses for Thermoplastics

Thermoplastics are widely used in packaging, automotive parts, and consumer goods due to their ability to be repeatedly melted and reshaped without altering their chemical properties. Common thermoplastic materials include polyethylene, polypropylene, and polyvinyl chloride, favored for their durability, flexibility, and cost-effectiveness. Their recyclability and ease of processing make thermoplastics ideal for applications like containers, toys, medical devices, and electronic housings.

Mechanical and Thermal Properties Comparison

Thermoset plastics exhibit superior mechanical strength and thermal stability due to their cross-linked polymer structure, making them ideal for high-temperature applications and structural components. Thermoplastics, characterized by linear or branched polymers, offer greater flexibility and impact resistance but have lower thermal resistance and mechanical strength compared to thermosets. The glass transition temperature for thermosets typically ranges from 150degC to 250degC, whereas thermoplastics vary widely, often melting between 200degC and 350degC, influencing their processing and end-use performance.

Processing and Manufacturing Differences

Thermosets undergo irreversible curing through heat or chemical reactions, forming rigid, heat-resistant structures ideal for high-strength applications, whereas thermoplastics melt and solidify repeatedly, allowing easier reshaping and recycling during manufacturing. Thermoset processing involves molding techniques such as compression and transfer molding with longer curing times, while thermoplastics are processed via injection molding, extrusion, and thermoforming with faster cycle times. The distinct thermal behavior impacts production speed, tooling costs, and end-use properties, making thermoplastics preferable for complex, flexible designs and thermosets suited for durable, heat-resistant parts.

Environmental Impact: Thermoset vs Thermoplastic

Thermoset plastics, once cured, are chemically cross-linked and cannot be remelted, resulting in limited recyclability and accumulation in landfills, contributing to long-term environmental pollution. Thermoplastics, on the other hand, are recyclable through melting and reshaping processes, enabling circular use and reducing plastic waste in ecosystems. The environmental impact of thermoplastics is generally lower due to higher recyclability rates and opportunities for reuse compared to the irreversible nature of thermoset polymers.

Choosing the Right Plastic for Your Product

Thermoset plastics offer high heat resistance and structural stability, making them ideal for durable, high-performance applications such as automotive parts and electrical insulators. Thermoplastics provide flexibility and ease of molding, suitable for consumer goods and packaging where recyclability and impact resistance are important. Selecting the right plastic depends on product requirements including thermal stability, mechanical strength, and recyclability considerations.

Thermoset vs Thermoplastic Infographic

materialdif.com

materialdif.com