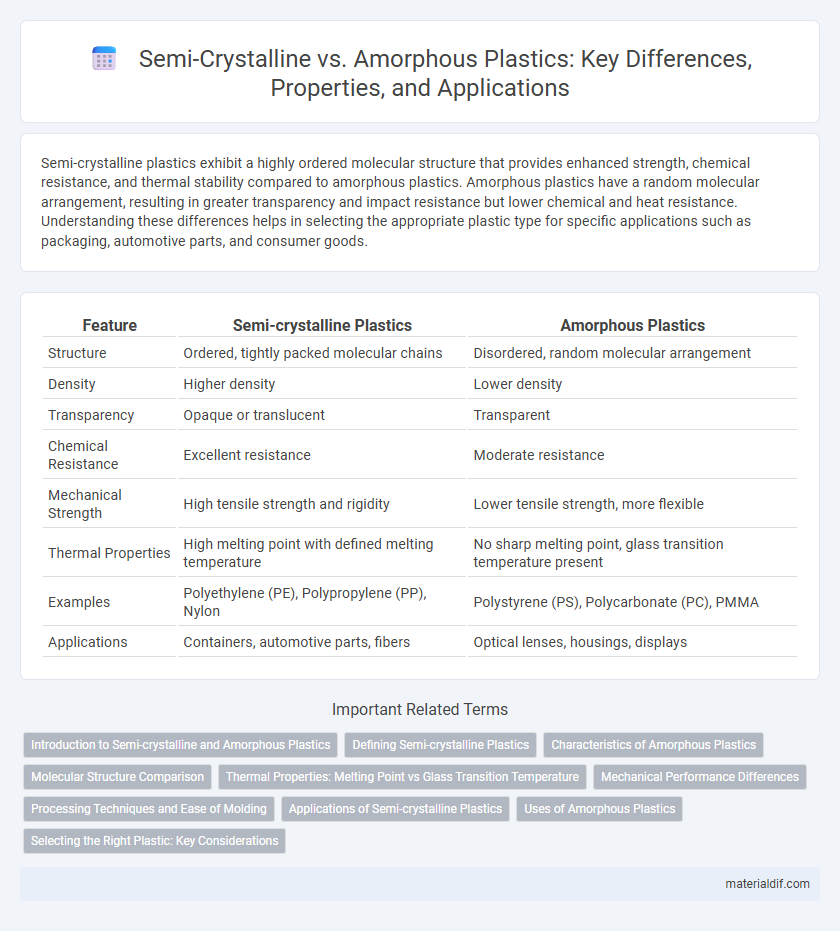

Semi-crystalline plastics exhibit a highly ordered molecular structure that provides enhanced strength, chemical resistance, and thermal stability compared to amorphous plastics. Amorphous plastics have a random molecular arrangement, resulting in greater transparency and impact resistance but lower chemical and heat resistance. Understanding these differences helps in selecting the appropriate plastic type for specific applications such as packaging, automotive parts, and consumer goods.

Table of Comparison

| Feature | Semi-crystalline Plastics | Amorphous Plastics |

|---|---|---|

| Structure | Ordered, tightly packed molecular chains | Disordered, random molecular arrangement |

| Density | Higher density | Lower density |

| Transparency | Opaque or translucent | Transparent |

| Chemical Resistance | Excellent resistance | Moderate resistance |

| Mechanical Strength | High tensile strength and rigidity | Lower tensile strength, more flexible |

| Thermal Properties | High melting point with defined melting temperature | No sharp melting point, glass transition temperature present |

| Examples | Polyethylene (PE), Polypropylene (PP), Nylon | Polystyrene (PS), Polycarbonate (PC), PMMA |

| Applications | Containers, automotive parts, fibers | Optical lenses, housings, displays |

Introduction to Semi-crystalline and Amorphous Plastics

Semi-crystalline plastics possess highly ordered molecular structures that create distinct melting points and enhanced mechanical strength, making them suitable for applications requiring durability and thermal resistance. In contrast, amorphous plastics have random molecular arrangements, resulting in gradual softening over a temperature range and superior optical clarity. Understanding the differences in molecular structure between semi-crystalline and amorphous plastics is crucial for selecting materials based on performance requirements such as flexibility, toughness, and chemical resistance.

Defining Semi-crystalline Plastics

Semi-crystalline plastics consist of ordered, tightly packed polymer chains forming crystalline regions interspersed with amorphous areas, resulting in distinct melting points and higher chemical resistance. Common examples include polyethylene, polypropylene, and nylon, which exhibit enhanced mechanical strength and thermal stability compared to amorphous plastics. Their partially ordered structure enables superior barrier properties and dimensional stability, making them ideal for packaging, automotive, and medical applications.

Characteristics of Amorphous Plastics

Amorphous plastics, such as polystyrene and polycarbonate, exhibit a disordered molecular structure lacking a clear melting point, resulting in gradual softening over a temperature range. These plastics typically offer superior optical clarity, impact resistance, and dimensional stability compared to semi-crystalline plastics. Their non-crystalline arrangement also leads to lower chemical resistance and higher water absorption, affecting their suitability for certain applications.

Molecular Structure Comparison

Semi-crystalline plastics possess a highly ordered molecular structure characterized by tightly packed polymer chains forming crystalline regions, which result in higher density and enhanced mechanical strength. In contrast, amorphous plastics exhibit a random, disordered arrangement of polymer chains lacking long-range order, leading to increased transparency and improved impact resistance. The molecular structure significantly influences thermal properties, with semi-crystalline plastics showing distinct melting points and amorphous plastics displaying gradual softening behavior.

Thermal Properties: Melting Point vs Glass Transition Temperature

Semi-crystalline plastics exhibit a distinct melting point due to their ordered molecular structure, allowing precise thermal processing and reshaping at elevated temperatures. Amorphous plastics lack a defined melting point and instead soften over a range defined by the glass transition temperature (Tg), which marks the transition from a rigid to a rubbery state. The thermal stability and heat resistance of semi-crystalline plastics generally surpass those of amorphous types, making them suitable for applications requiring higher thermal endurance.

Mechanical Performance Differences

Semi-crystalline plastics exhibit higher tensile strength, chemical resistance, and thermal stability due to their ordered molecular structure, making them ideal for high-performance applications. Amorphous plastics, characterized by a random molecular arrangement, provide better impact resistance and clarity but generally have lower mechanical strength and thermal resistance. The crystalline regions in semi-crystalline plastics contribute to rigidity and dimensional stability, while amorphous plastics offer superior flexibility and ease of processing.

Processing Techniques and Ease of Molding

Semi-crystalline plastics, such as polyethylene and polypropylene, exhibit distinct melting points that allow precise temperature control during injection molding and extrusion, enabling efficient processing with high dimensional stability. Amorphous plastics like polystyrene and polycarbonate soften over a temperature range, facilitating easier thermoforming and blow molding but often requiring careful cooling to avoid warping. The crystalline structure in semi-crystalline plastics enhances moldability with faster cycle times, whereas amorphous plastics demand slower cooling yet offer superior surface finish and transparency.

Applications of Semi-crystalline Plastics

Semi-crystalline plastics, characterized by their organized molecular structure, are widely used in applications requiring high mechanical strength and chemical resistance, such as automotive components, packaging films, and medical devices. Their enhanced durability and thermal stability make them ideal for manufacturing pipes, containers, and electrical insulation materials where prolonged performance under stress is crucial. Common semi-crystalline polymers include polyethylene (PE), polypropylene (PP), and polyamide (nylon), each serving specialized roles across industrial and consumer products.

Uses of Amorphous Plastics

Amorphous plastics, characterized by their irregular molecular structure, are widely used in applications requiring transparency and impact resistance, such as optical lenses, medical devices, and food packaging. Their excellent clarity and ability to form smooth surfaces make them ideal for consumer electronics housings and display screens. Common amorphous plastics like polycarbonate and polymethyl methacrylate (PMMA) are favored for their dimensional stability and resistance to ultraviolet light.

Selecting the Right Plastic: Key Considerations

Selecting the right plastic involves understanding the distinct properties of semi-crystalline and amorphous plastics, such as crystallinity, thermal resistance, and mechanical strength. Semi-crystalline plastics like polyethylene and polypropylene offer higher chemical resistance and toughness, while amorphous plastics like polystyrene and polycarbonate provide better clarity and dimensional stability. Key considerations include the application's temperature range, impact resistance requirements, and environmental exposure to ensure optimal performance and durability.

Semi-crystalline vs Amorphous Plastics Infographic

materialdif.com

materialdif.com