Bioplastics are derived from renewable biomass sources such as corn starch or sugarcane, making them more environmentally sustainable compared to petroplastics, which are produced from non-renewable fossil fuels. Bioplastics often offer biodegradability or compostability, reducing landfill waste and pollution, whereas petroplastics can persist in the environment for hundreds of years. The shift towards bioplastics aims to lower carbon footprints and dependence on oil, addressing key issues of plastic pollution and resource depletion.

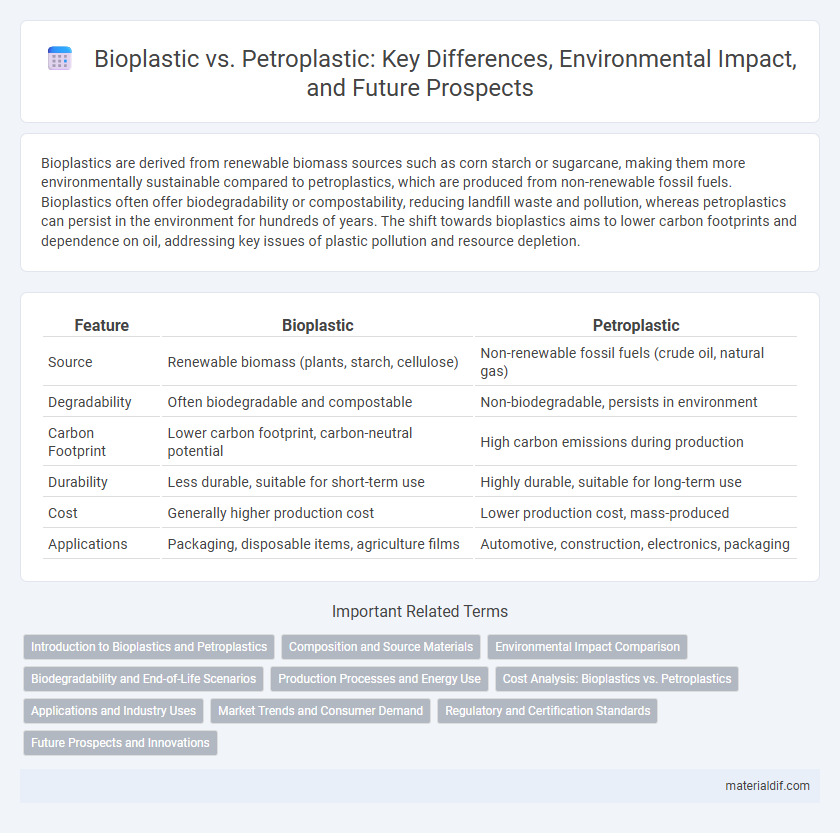

Table of Comparison

| Feature | Bioplastic | Petroplastic |

|---|---|---|

| Source | Renewable biomass (plants, starch, cellulose) | Non-renewable fossil fuels (crude oil, natural gas) |

| Degradability | Often biodegradable and compostable | Non-biodegradable, persists in environment |

| Carbon Footprint | Lower carbon footprint, carbon-neutral potential | High carbon emissions during production |

| Durability | Less durable, suitable for short-term use | Highly durable, suitable for long-term use |

| Cost | Generally higher production cost | Lower production cost, mass-produced |

| Applications | Packaging, disposable items, agriculture films | Automotive, construction, electronics, packaging |

Introduction to Bioplastics and Petroplastics

Bioplastics are derived from renewable biomass sources such as corn starch, sugarcane, and cellulose, offering a sustainable alternative to petroplastics, which are synthesized from fossil fuels like crude oil and natural gas. Petroplastics dominate the global plastic market due to their durability and cost-effectiveness, but their environmental impact drives demand for biodegradable and compostable bioplastics. Innovations in bioplastic production focus on reducing carbon footprint and improving biodegradability while maintaining functionality comparable to conventional petroplastics.

Composition and Source Materials

Bioplastics are primarily derived from renewable biomass sources such as corn starch, sugarcane, or cellulose, whereas petroplastics are synthesized from non-renewable fossil fuels like crude oil and natural gas. The molecular composition of bioplastics often includes polymers like polylactic acid (PLA) or polyhydroxyalkanoates (PHA), contrasting with petroplastics which are mainly composed of polyethylene (PE), polypropylene (PP), and polystyrene (PS). The reliance on biological feedstocks in bioplastics offers a sustainable pathway compared to the carbon-intensive extraction and refinement processes associated with petroplastics.

Environmental Impact Comparison

Bioplastics, derived from renewable biomass such as corn starch or sugarcane, typically generate fewer greenhouse gas emissions and exhibit higher biodegradability compared to petroplastics, which rely on non-renewable fossil fuels and persist in the environment for centuries. The production of petroplastics contributes significantly to carbon dioxide emissions and ocean pollution, exacerbating climate change and marine ecosystem degradation. However, bioplastics often require specific industrial composting conditions for effective decomposition, limiting their environmental benefits relative to certain naturally degradable materials.

Biodegradability and End-of-Life Scenarios

Bioplastics, derived from renewable biomass sources, exhibit enhanced biodegradability compared to petroplastics, which originate from fossil fuels and degrade slowly over centuries. In end-of-life scenarios, bioplastics can be composted industrially or biodegraded in specific conditions, reducing landfill accumulation and environmental persistence. Petroplastics primarily require mechanical recycling or energy recovery, often leading to long-term environmental pollution due to their resistance to natural decomposition.

Production Processes and Energy Use

Bioplastics are primarily produced from renewable biomass sources such as corn starch, sugarcane, or cellulose, utilizing fermentation and polymerization processes that generally consume less fossil fuel energy. Petroplastics derive from petroleum through complex refining and polymerization steps that demand high energy input, often from non-renewable sources. Energy consumption during bioplastic production is frequently lower due to the use of biomass feedstocks, resulting in reduced greenhouse gas emissions compared to conventional petroplastic manufacturing.

Cost Analysis: Bioplastics vs. Petroplastics

Bioplastics generally incur higher production costs compared to petroplastics, primarily due to raw material prices and less mature manufacturing processes. Petroplastics benefit from established supply chains and economies of scale, leading to lower unit costs and widespread availability. Despite higher costs, bioplastics offer potential long-term economic advantages through biodegradability and reduced environmental impact, which can translate to cost savings in waste management and regulatory compliance.

Applications and Industry Uses

Bioplastics, derived from renewable biomass sources like corn starch and sugarcane, are widely used in packaging, agriculture, and disposable utensils due to their biodegradability and reduced environmental impact. Petroplastics, made from fossil fuels, dominate applications requiring durability and chemical resistance, such as automotive parts, electronics, and construction materials. Industries prioritize bioplastics for eco-friendly solutions in food packaging and single-use items, while petroplastics remain essential in heavy-duty manufacturing and long-lasting consumer goods.

Market Trends and Consumer Demand

Bioplastics are experiencing rapid market growth driven by increasing consumer demand for sustainable and eco-friendly alternatives, with the global bioplastics market projected to reach over $20 billion by 2027. Petroplastics continue to dominate due to lower costs and established manufacturing infrastructure, but regulatory pressures and environmental concerns are shifting preference toward bioplastics. Innovations in biodegradable materials and improved performance are accelerating bioplastic adoption across packaging, automotive, and consumer goods sectors.

Regulatory and Certification Standards

Bioplastics and petroplastics are subject to distinct regulatory and certification standards that emphasize sustainability and environmental impact. Bioplastics often comply with standards such as ASTM D6400 and EN 13432, which certify compostability and biodegradability, while petroplastics are regulated under frameworks addressing chemical safety and fossil fuel usage like REACH and EPA guidelines. Compliance with these certifications ensures bioplastics meet strict eco-friendly criteria, promoting reduced carbon footprint and waste management efficiency compared to traditional petroplastic products.

Future Prospects and Innovations

Bioplastics, derived from renewable biomass sources like corn starch and sugarcane, show promising innovations in biodegradability and carbon footprint reduction compared to traditional petroplastics made from fossil fuels. Advances in enzyme technology and microbial fermentation are enhancing the efficiency and cost-effectiveness of bioplastic production, making it a competitive alternative in packaging, agriculture, and automotive industries. Future prospects include the development of fully compostable materials and increased recycling technologies, which could significantly reduce plastic pollution and dependence on non-renewable resources.

Bioplastic vs Petroplastic Infographic

materialdif.com

materialdif.com