Flame retardant additives are incorporated into plastics to reduce their flammability and slow down the spread of fire, enhancing safety in various applications. UV stabilizers protect plastics from degradation caused by ultraviolet radiation, preventing discoloration, brittleness, and loss of mechanical properties. Both additives improve the durability and lifespan of plastic materials, but they target different environmental challenges--fire hazards versus UV exposure.

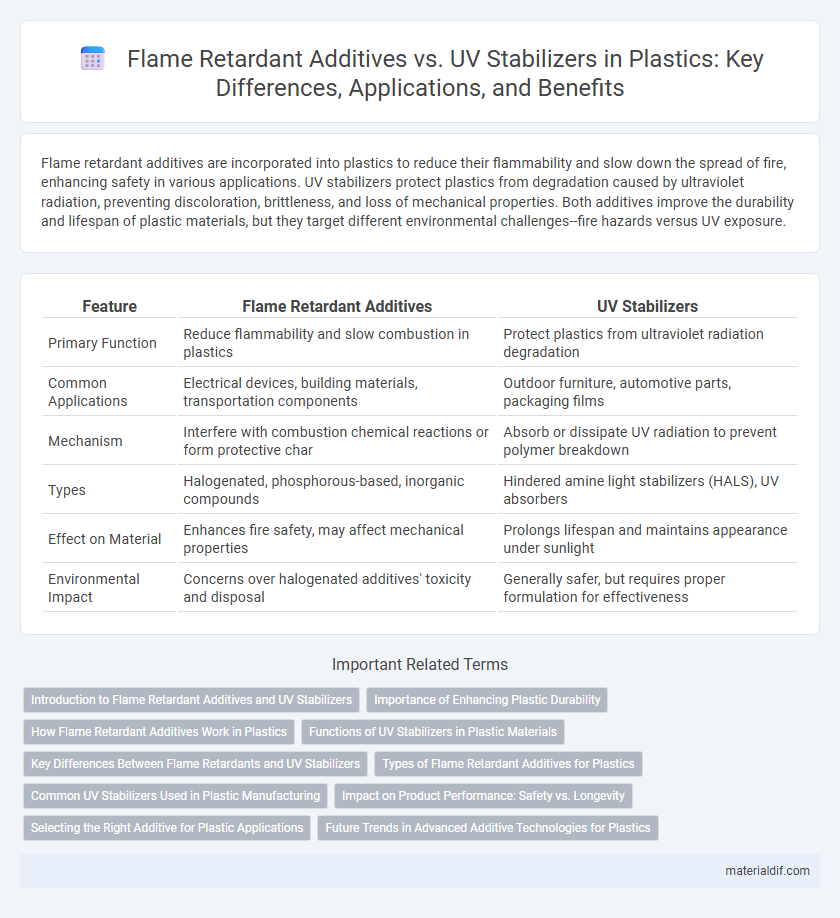

Table of Comparison

| Feature | Flame Retardant Additives | UV Stabilizers |

|---|---|---|

| Primary Function | Reduce flammability and slow combustion in plastics | Protect plastics from ultraviolet radiation degradation |

| Common Applications | Electrical devices, building materials, transportation components | Outdoor furniture, automotive parts, packaging films |

| Mechanism | Interfere with combustion chemical reactions or form protective char | Absorb or dissipate UV radiation to prevent polymer breakdown |

| Types | Halogenated, phosphorous-based, inorganic compounds | Hindered amine light stabilizers (HALS), UV absorbers |

| Effect on Material | Enhances fire safety, may affect mechanical properties | Prolongs lifespan and maintains appearance under sunlight |

| Environmental Impact | Concerns over halogenated additives' toxicity and disposal | Generally safer, but requires proper formulation for effectiveness |

Introduction to Flame Retardant Additives and UV Stabilizers

Flame retardant additives are specialized chemicals incorporated into plastics to inhibit or resist the spread of fire by interfering with the combustion process, enhancing material safety in applications such as electronics and construction. UV stabilizers protect plastics from degradation caused by ultraviolet radiation, preventing discoloration, loss of mechanical properties, and surface erosion in outdoor environments. Both flame retardant additives and UV stabilizers play crucial roles in extending the durability and performance of plastic products under specific environmental stressors.

Importance of Enhancing Plastic Durability

Flame retardant additives play a crucial role in preventing the ignition and spread of fire in plastic materials, thereby enhancing safety and extending product lifespan. UV stabilizers protect plastics from degradation caused by ultraviolet radiation, maintaining structural integrity and color stability over prolonged outdoor exposure. Combining these additives significantly improves overall plastic durability, ensuring materials withstand environmental stressors and reduce premature failure.

How Flame Retardant Additives Work in Plastics

Flame retardant additives in plastics function by interrupting the combustion process through chemical and physical mechanisms such as promoting char formation, releasing flame-inhibiting gases, and diluting flammable gases. These additives often include compounds like brominated flame retardants, phosphorus-based, or metal hydroxides that enhance fire resistance without compromising material properties. By reducing heat release and slowing flame propagation, flame retardant additives significantly improve the safety and durability of plastic products in various applications.

Functions of UV Stabilizers in Plastic Materials

UV stabilizers in plastic materials primarily function to absorb or block harmful ultraviolet radiation, preventing degradation and maintaining the polymer's mechanical strength and appearance. These additives significantly extend the lifespan of plastics exposed to sunlight by inhibiting photochemical reactions that cause discoloration, cracking, and brittleness. Unlike flame retardant additives that enhance fire resistance, UV stabilizers specialize in protecting plastics from the damaging effects of UV light, ensuring durability and reliability in outdoor applications.

Key Differences Between Flame Retardants and UV Stabilizers

Flame retardant additives primarily enhance plastic's resistance to ignition and slow down the spread of fire by interfering with the combustion process. UV stabilizers protect plastics by absorbing or reflecting ultraviolet radiation, preventing degradation, discoloration, and loss of mechanical properties caused by sun exposure. While flame retardants target fire safety, UV stabilizers extend the material's lifespan under sunlight, making these additives essential for different environmental challenges.

Types of Flame Retardant Additives for Plastics

Flame retardant additives for plastics include halogenated compounds, phosphorus-based additives, metal hydroxides, and nitrogen-based retardants, each offering unique fire-resistant properties. Halogenated flame retardants are effective but raise environmental concerns, while metal hydroxides such as aluminum trihydrate release water vapor to cool materials during combustion. Phosphorus and nitrogen-based additives promote charring and form protective layers, enhancing the plastic's resistance to ignition and flame spread.

Common UV Stabilizers Used in Plastic Manufacturing

Common UV stabilizers used in plastic manufacturing include hindered amine light stabilizers (HALS), UV absorbers like benzophenones and benzotriazoles, and quenchers that prevent photodegradation. HALS are highly effective in scavenging free radicals formed during UV exposure, significantly extending the lifespan of plastic materials. These additives work by protecting the polymer chains from breaking down under sunlight, thus maintaining the plastic's physical properties and appearance.

Impact on Product Performance: Safety vs. Longevity

Flame retardant additives significantly enhance plastic product safety by reducing flammability and slowing combustion, critical for applications in construction and electronics. UV stabilizers improve longevity by protecting plastics from degradation caused by ultraviolet radiation, preventing color fading and loss of mechanical properties in outdoor environments. Balancing these additives is essential for optimizing both fire safety and durability, depending on the intended use of the plastic product.

Selecting the Right Additive for Plastic Applications

Flame retardant additives enhance plastic safety by reducing flammability and preventing fire spread, making them essential for electronics and building materials. UV stabilizers protect plastics from degradation caused by ultraviolet radiation, extending the lifespan of outdoor applications such as automotive parts and agricultural films. Selecting the right additive depends on the specific environmental exposure and performance requirements, balancing fire resistance with UV durability to optimize plastic functionality.

Future Trends in Advanced Additive Technologies for Plastics

Flame retardant additives and UV stabilizers are evolving with innovations in nanotechnology and bio-based compounds that enhance durability and environmental sustainability in plastics. Future trends emphasize multifunctional additives combining flame resistance and UV protection to extend the lifespan of plastic materials in extreme conditions. Smart additives with self-healing and responsive properties are gaining momentum, promising improved performance and reduced material degradation in advanced plastic applications.

Flame Retardant Additives vs UV Stabilizers Infographic

materialdif.com

materialdif.com