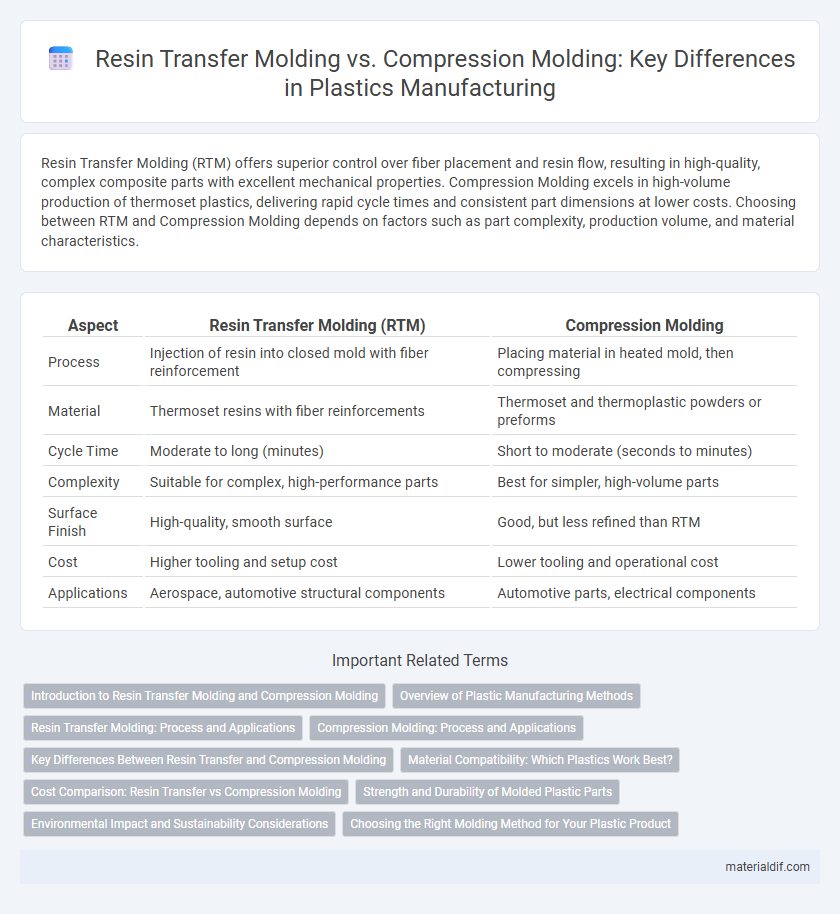

Resin Transfer Molding (RTM) offers superior control over fiber placement and resin flow, resulting in high-quality, complex composite parts with excellent mechanical properties. Compression Molding excels in high-volume production of thermoset plastics, delivering rapid cycle times and consistent part dimensions at lower costs. Choosing between RTM and Compression Molding depends on factors such as part complexity, production volume, and material characteristics.

Table of Comparison

| Aspect | Resin Transfer Molding (RTM) | Compression Molding |

|---|---|---|

| Process | Injection of resin into closed mold with fiber reinforcement | Placing material in heated mold, then compressing |

| Material | Thermoset resins with fiber reinforcements | Thermoset and thermoplastic powders or preforms |

| Cycle Time | Moderate to long (minutes) | Short to moderate (seconds to minutes) |

| Complexity | Suitable for complex, high-performance parts | Best for simpler, high-volume parts |

| Surface Finish | High-quality, smooth surface | Good, but less refined than RTM |

| Cost | Higher tooling and setup cost | Lower tooling and operational cost |

| Applications | Aerospace, automotive structural components | Automotive parts, electrical components |

Introduction to Resin Transfer Molding and Compression Molding

Resin Transfer Molding (RTM) involves injecting resin into a closed mold containing a fiber preform, ensuring high fiber volume and excellent surface finish. Compression Molding uses heat and pressure to shape thermoset or thermoplastic materials within a heated mold cavity, ideal for high-volume production of durable parts. Both methods offer distinct advantages in composite manufacturing, with RTM favored for complex geometries and Compression Molding for rapid cycle times and consistent quality.

Overview of Plastic Manufacturing Methods

Resin Transfer Molding (RTM) is a closed mold process where resin is injected into a mold containing fiber reinforcements, offering high precision and complex shapes with excellent surface finish. Compression Molding involves placing a preheated plastic charge into an open mold cavity, then applying heat and pressure to form dense, high-strength parts ideal for large-volume production. Both methods are widely used in plastic manufacturing for composite materials, with RTM favored for intricate designs and Compression Molding preferred for rapid and cost-effective mass production.

Resin Transfer Molding: Process and Applications

Resin Transfer Molding (RTM) involves injecting resin into a closed mold containing a fiber preform, allowing for precise control over fiber placement and resin distribution. This process is widely used in aerospace, automotive, and marine industries for producing high-strength, lightweight composite parts with complex geometries. RTM offers advantages such as low void content, high fiber volume fraction, and repeatability, making it ideal for structural components requiring superior mechanical properties.

Compression Molding: Process and Applications

Compression molding involves placing pre-measured resin and reinforcement materials into a heated mold cavity, where pressure is applied to shape and cure the composite. This process is ideal for producing high-strength, complex-shaped parts with excellent surface finish, commonly used in automotive components, electrical housings, and industrial equipment. Compression molding offers advantages like low material waste, fast cycle times, and suitability for large-volume production of thermoset plastics and fiber-reinforced composites.

Key Differences Between Resin Transfer and Compression Molding

Resin Transfer Molding (RTM) involves injecting resin into a closed mold containing a fiber preform, resulting in high-strength, lightweight composite parts ideal for complex shapes and aerospace industries. Compression Molding uses heat and pressure to shape thermoset or thermoplastic materials in an open mold, offering faster production cycles suitable for high-volume automotive components. Key differences lie in mold design, material handling, and part complexity, with RTM providing superior surface finish and mechanical properties, whereas compression molding excels in cost-effectiveness and cycle time.

Material Compatibility: Which Plastics Work Best?

Resin Transfer Molding (RTM) excels with thermosetting plastics like epoxy, polyester, and vinyl ester resins due to its ability to infuse resin efficiently into fiber reinforcements, creating strong composite materials. Compression Molding is highly compatible with thermoplastics and thermosets such as phenolics, melamines, and certain polyamides, offering excellent control over material flow and high production rates. Choosing between RTM and Compression Molding depends on the plastic's viscosity, curing characteristics, and desired mechanical properties of the final product.

Cost Comparison: Resin Transfer vs Compression Molding

Resin Transfer Molding (RTM) generally incurs higher initial tooling costs compared to Compression Molding due to the complexity of mold design and injection systems. Compression Molding offers lower per-part costs in high-volume production because of its faster cycle times and simpler tooling requirements, making it more cost-effective for large batches. RTM provides better material utilization and quality for intricate designs, but overall, Compression Molding remains the more economical choice for mass production with standard geometries.

Strength and Durability of Molded Plastic Parts

Resin Transfer Molding (RTM) produces plastic parts with superior strength due to its controlled resin infusion, resulting in fewer voids and higher fiber content compared to Compression Molding. Compression Molding offers excellent durability with uniform pressure distribution, but may have lower fiber volume fraction impacting overall mechanical performance. For applications demanding high-strength and long-lasting components, RTM typically delivers enhanced structural integrity and resistance to fatigue.

Environmental Impact and Sustainability Considerations

Resin Transfer Molding (RTM) offers enhanced material efficiency by precisely injecting resin into molds, reducing waste compared to Compression Molding, which often results in higher scrap rates due to excess resin usage. RTM enables better control of resin flow, minimizing emissions of volatile organic compounds (VOCs) and contributing to lower environmental impact during the manufacturing process. Compression Molding, while faster and suitable for high-volume production, typically consumes more energy and generates greater material waste, making RTM a more sustainable choice for eco-conscious composite manufacturing.

Choosing the Right Molding Method for Your Plastic Product

Resin Transfer Molding (RTM) offers precise control over fiber placement and resin infusion, making it ideal for complex, high-strength composite parts with tight tolerances. Compression Molding excels in high-volume production of thermosetting plastics, providing efficient cycle times and consistent part quality. Selecting the right molding method depends on factors like part complexity, production volume, material type, and cost considerations to optimize performance and manufacturing efficiency.

Resin Transfer Molding vs Compression Molding Infographic

materialdif.com

materialdif.com