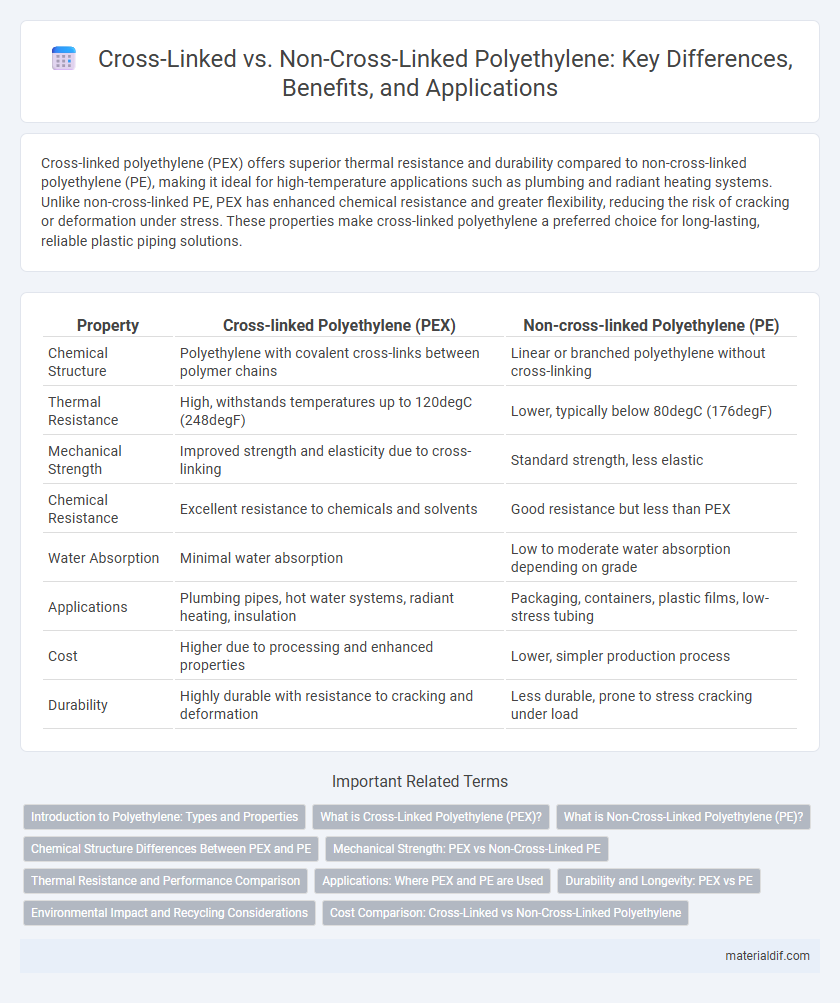

Cross-linked polyethylene (PEX) offers superior thermal resistance and durability compared to non-cross-linked polyethylene (PE), making it ideal for high-temperature applications such as plumbing and radiant heating systems. Unlike non-cross-linked PE, PEX has enhanced chemical resistance and greater flexibility, reducing the risk of cracking or deformation under stress. These properties make cross-linked polyethylene a preferred choice for long-lasting, reliable plastic piping solutions.

Table of Comparison

| Property | Cross-linked Polyethylene (PEX) | Non-cross-linked Polyethylene (PE) |

|---|---|---|

| Chemical Structure | Polyethylene with covalent cross-links between polymer chains | Linear or branched polyethylene without cross-linking |

| Thermal Resistance | High, withstands temperatures up to 120degC (248degF) | Lower, typically below 80degC (176degF) |

| Mechanical Strength | Improved strength and elasticity due to cross-linking | Standard strength, less elastic |

| Chemical Resistance | Excellent resistance to chemicals and solvents | Good resistance but less than PEX |

| Water Absorption | Minimal water absorption | Low to moderate water absorption depending on grade |

| Applications | Plumbing pipes, hot water systems, radiant heating, insulation | Packaging, containers, plastic films, low-stress tubing |

| Cost | Higher due to processing and enhanced properties | Lower, simpler production process |

| Durability | Highly durable with resistance to cracking and deformation | Less durable, prone to stress cracking under load |

Introduction to Polyethylene: Types and Properties

Cross-linked polyethylene (PEX) features a chemically bonded network structure that enhances thermal resistance, mechanical strength, and chemical stability compared to non-cross-linked polyethylene (PE). Non-cross-linked polyethylene, such as low-density polyethylene (LDPE) and high-density polyethylene (HDPE), offers flexibility, ease of processing, and cost-effectiveness but lacks the improved durability found in PEX. Both types serve diverse applications, with PEX commonly used in plumbing and radiant heating due to its superior performance under heat and pressure.

What is Cross-Linked Polyethylene (PEX)?

Cross-Linked Polyethylene (PEX) is a type of polyethylene in which the molecular chains are chemically bonded to form a three-dimensional network, enhancing its thermal and mechanical properties. PEX exhibits superior resistance to heat, pressure, and chemical degradation compared to non-cross-linked polyethylene, making it ideal for plumbing, radiant heating, and industrial piping applications. This cross-linking process improves flexibility and durability while reducing the material's susceptibility to stress cracking and deformation.

What is Non-Cross-Linked Polyethylene (PE)?

Non-Cross-Linked Polyethylene (PE) is a thermoplastic polymer characterized by linear molecular chains without covalent bonds between them, resulting in a flexible and less heat-resistant material compared to cross-linked variants. Commonly used in packaging, plastic bags, and containers, non-cross-linked PE offers excellent chemical resistance and ease of processing through extrusion or molding. Its lower density and softness make it suitable for applications requiring impact resistance and flexibility but limit its performance in high-temperature environments.

Chemical Structure Differences Between PEX and PE

Cross-linked polyethylene (PEX) features a three-dimensional network of covalent bonds formed between polymer chains, enhancing thermal stability and mechanical strength compared to non-cross-linked polyethylene (PE), which consists of linear or slightly branched polymer chains. The chemical cross-linking in PEX restricts molecular movement, reducing susceptibility to deformation and chemical attack. In contrast, PE's simpler molecular structure results in lower temperature tolerance and decreased resistance to environmental stress cracking.

Mechanical Strength: PEX vs Non-Cross-Linked PE

Cross-linked polyethylene (PEX) exhibits superior mechanical strength compared to non-cross-linked polyethylene due to its enhanced molecular network, providing increased resistance to stress, temperature variations, and deformation. The cross-linking process in PEX improves its tensile strength, impact resistance, and durability under high pressure, making it ideal for applications such as plumbing and radiant heating systems. Non-cross-linked polyethylene, lacking this molecular bonding, demonstrates lower mechanical robustness and is more prone to creep and mechanical fatigue over time.

Thermal Resistance and Performance Comparison

Cross-linked polyethylene (PEX) exhibits superior thermal resistance compared to non-cross-linked polyethylene (PE), maintaining structural integrity at temperatures up to 120degC, while non-cross-linked variants typically degrade around 80-90degC. The cross-linking process enhances polymer chain stability, resulting in improved mechanical strength, chemical resistance, and longevity under thermal stress. Consequently, PEX is preferred in applications requiring high performance in heat exposure environments such as plumbing and radiant heating systems.

Applications: Where PEX and PE are Used

Cross-linked polyethylene (PEX) is widely used in plumbing, radiant heating systems, and medical tubing due to its enhanced thermal resistance and flexibility. Non-cross-linked polyethylene (PE) finds applications in packaging, plastic bags, and containers, benefiting from its chemical resistance and ease of processing. PEX is preferred in environments requiring durability under high pressure and temperature, whereas PE is commonly chosen for lightweight, cost-effective solutions in everyday products.

Durability and Longevity: PEX vs PE

Cross-linked polyethylene (PEX) exhibits superior durability and longevity compared to non-cross-linked polyethylene (PE) due to its enhanced molecular structure, which provides increased resistance to mechanical stress, chemical exposure, and temperature fluctuations. PEX maintains structural integrity under high pressure and prolonged heat, making it ideal for plumbing and heating applications where durability is crucial. Non-cross-linked PE typically shows reduced lifespan and is more prone to deformation and degradation in demanding environments, limiting its use in long-term installations.

Environmental Impact and Recycling Considerations

Cross-linked polyethylene (PEX) exhibits enhanced durability but poses significant challenges for recycling due to its thermoset structure, which prevents remelting and reshaping, leading to increased landfill accumulation. Non-cross-linked polyethylene (PE), typically high-density polyethylene (HDPE) or low-density polyethylene (LDPE), is widely recyclable and has a lower environmental footprint, providing substantial advantages in circular economy applications. Environmental assessments favor non-cross-linked polyethylene for sustainability, given its compatibility with existing recycling infrastructure and reduced long-term pollution risks.

Cost Comparison: Cross-Linked vs Non-Cross-Linked Polyethylene

Cross-linked polyethylene (PEX) generally incurs higher production and installation costs compared to non-cross-linked polyethylene (PE) due to its enhanced thermal and mechanical properties achieved through a cross-linking process. Non-cross-linked polyethylene remains more cost-effective for applications requiring lower temperature and pressure resistance, offering simplicity in fabrication and repair. Evaluating total lifecycle expenses, PEX's durability and longer service life can offset initial cost differences in demanding environments.

Cross-linked Polyethylene vs Non-cross-linked Polyethylene Infographic

materialdif.com

materialdif.com