Plastic alloying enhances material properties by combining polymers with additives or other polymers to achieve improved strength, flexibility, and chemical resistance compared to pure polymers. Pure polymers offer simplicity and uniformity in molecular structure but often lack the tailored performance required for specialized applications. Selecting between plastic alloying and pure polymers depends on the desired mechanical characteristics, cost-effectiveness, and end-use environmental conditions.

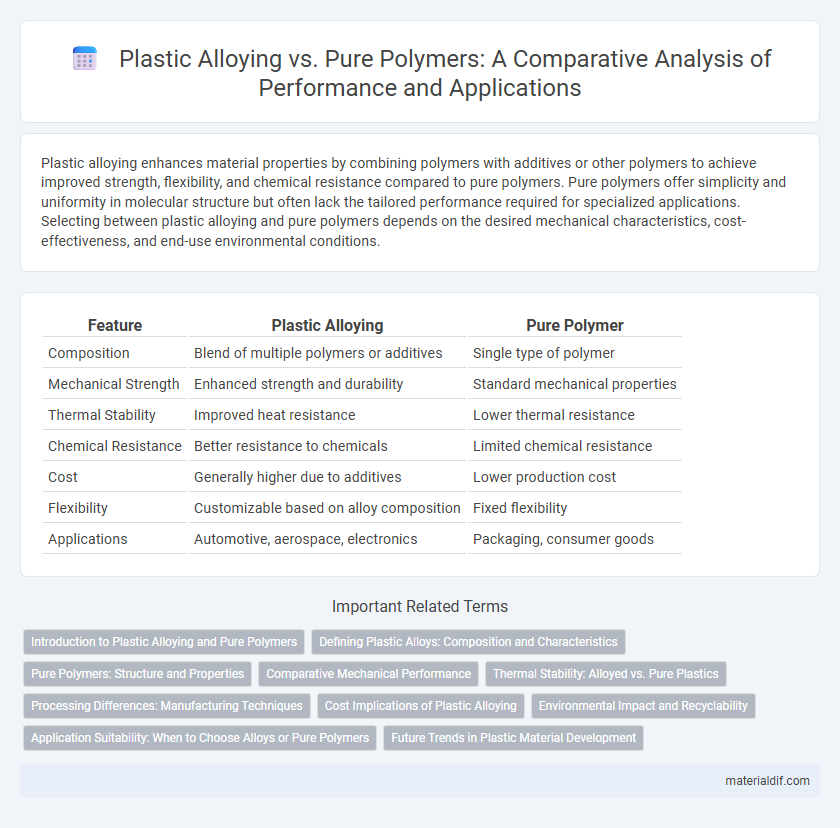

Table of Comparison

| Feature | Plastic Alloying | Pure Polymer |

|---|---|---|

| Composition | Blend of multiple polymers or additives | Single type of polymer |

| Mechanical Strength | Enhanced strength and durability | Standard mechanical properties |

| Thermal Stability | Improved heat resistance | Lower thermal resistance |

| Chemical Resistance | Better resistance to chemicals | Limited chemical resistance |

| Cost | Generally higher due to additives | Lower production cost |

| Flexibility | Customizable based on alloy composition | Fixed flexibility |

| Applications | Automotive, aerospace, electronics | Packaging, consumer goods |

Introduction to Plastic Alloying and Pure Polymers

Plastic alloying involves blending two or more polymers or adding fillers to enhance mechanical properties, chemical resistance, and thermal stability beyond those of pure polymers. Pure polymers consist of long chains of repeating molecular units, offering uniformity and predictability in performance but often limited by single-property constraints. The alloying process tailors plastics for specific applications by combining attributes of multiple polymers, resulting in materials optimized for strength, flexibility, or environmental resistance.

Defining Plastic Alloys: Composition and Characteristics

Plastic alloys consist of blends of two or more polymers or polymers mixed with additives, designed to combine specific physical, chemical, or mechanical properties that are often superior to pure polymers. The composition of plastic alloys enables enhanced performance traits such as improved impact resistance, flexibility, thermal stability, and chemical resistance, tailored for diverse industrial applications. Unlike pure polymers, plastic alloys offer customizable material characteristics by adjusting the ratios and types of components in their formulation.

Pure Polymers: Structure and Properties

Pure polymers consist of long, repeating molecular chains that define their intrinsic mechanical and thermal properties. Their molecular structure typically results in specific characteristics such as flexibility, tensile strength, and resistance to chemicals, which vary depending on the polymer type, for example, polyethylene or polystyrene. The absence of alloying agents in pure polymers leads to consistent performance and ease of recycling compared to plastic alloys.

Comparative Mechanical Performance

Plastic alloying enhances mechanical performance by combining multiple polymers to achieve superior strength, impact resistance, and thermal stability compared to pure polymers. Pure polymers often exhibit limitations in tensile strength and durability, whereas plastic alloys provide tailored mechanical properties optimized for specific applications. The synergistic effect of blending polymers results in materials with improved stiffness, toughness, and wear resistance, making plastic alloys preferable for high-performance engineering uses.

Thermal Stability: Alloyed vs. Pure Plastics

Alloyed plastics exhibit enhanced thermal stability compared to pure polymers due to the synergistic effects of combined polymer matrices and additives, which improve heat resistance and reduce degradation at elevated temperatures. Pure polymers often demonstrate limited thermal durability, leading to faster softening or decomposition under prolonged thermal stress. This makes plastic alloying a preferred choice for applications requiring sustained thermal performance and reliability.

Processing Differences: Manufacturing Techniques

Plastic alloying involves combining polymers with additives or other polymers to enhance properties, requiring specialized manufacturing techniques like compounding and twin-screw extrusion for uniform dispersion. Pure polymers typically undergo simpler processing methods such as injection molding or extrusion without extensive blending steps. The difference in processing complexity directly influences production speed, equipment requirements, and final material performance.

Cost Implications of Plastic Alloying

Plastic alloying generally involves combining multiple polymers or additives, which increases material complexity but can enhance performance properties such as strength, flexibility, and chemical resistance. The cost implications of plastic alloying include higher initial raw material expenses and more intricate processing requirements compared to pure polymers, often leading to increased production costs. However, the improved durability and functionality of alloyed plastics can reduce long-term expenses through extended product lifespan and decreased maintenance.

Environmental Impact and Recyclability

Plastic alloying enhances material properties but complicates recycling processes compared to pure polymers, which are easier to recycle due to their uniform composition. The environmental impact of plastic alloys is higher as mixed materials often require specialized recycling facilities, leading to increased energy consumption and waste generation. Pure polymers contribute to more efficient recycling streams, reducing landfill accumulation and lowering carbon footprints in plastic waste management.

Application Suitability: When to Choose Alloys or Pure Polymers

Plastic alloys offer enhanced mechanical properties and chemical resistance, making them ideal for demanding applications such as automotive parts and industrial components. Pure polymers provide excellent purity and processability, preferred in medical devices and food packaging where contamination risk must be minimized. Selecting between plastic alloying and pure polymers depends on balancing performance requirements with application-specific standards for durability and safety.

Future Trends in Plastic Material Development

Plastic alloying enhances mechanical strength, thermal stability, and chemical resistance compared to pure polymers, enabling advanced applications in automotive and aerospace industries. Future trends emphasize bio-based and recyclable alloys to address environmental concerns and regulatory pressures. Innovations in nanocomposite additives and compatibilizers further optimize performance, promoting sustainability and circular economy integration.

Plastic Alloying vs Pure Polymer Infographic

materialdif.com

materialdif.com