Plastic foaming involves introducing gas into a polymer matrix to create a lightweight, porous structure with enhanced insulation and cushioning properties. Plastic extrusion is a continuous manufacturing process where melted plastic is forced through a shaped die to produce uniform profiles like pipes, sheets, or films. While foaming improves thermal and acoustic insulation, extrusion provides precise dimensional control and consistent mechanical strength.

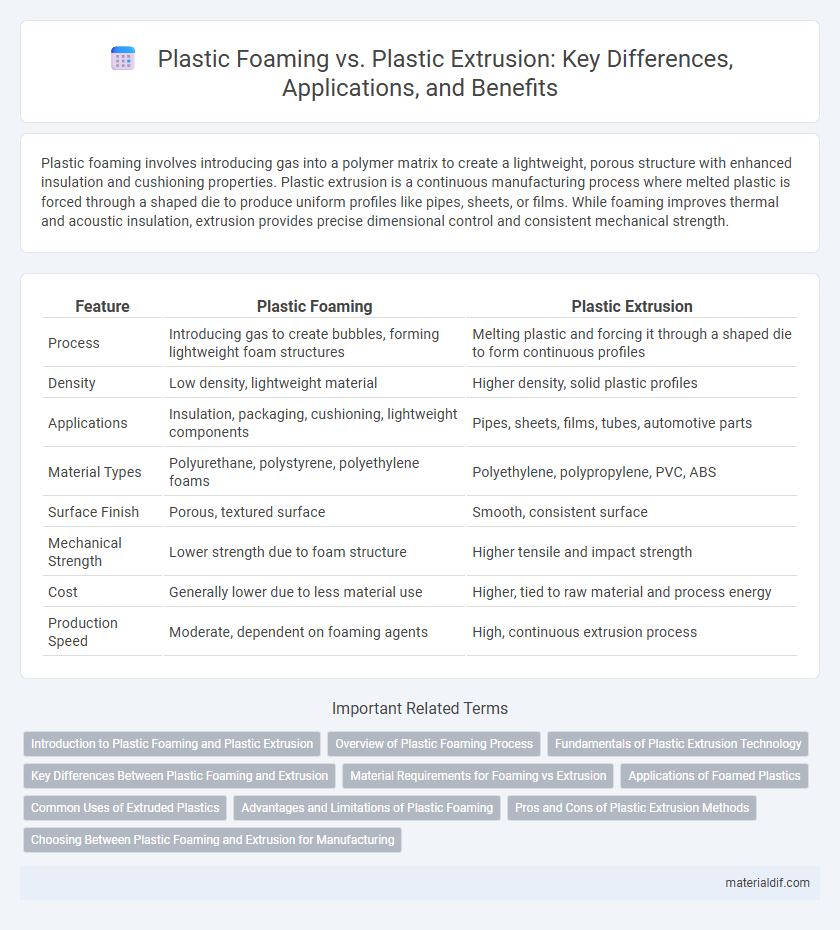

Table of Comparison

| Feature | Plastic Foaming | Plastic Extrusion |

|---|---|---|

| Process | Introducing gas to create bubbles, forming lightweight foam structures | Melting plastic and forcing it through a shaped die to form continuous profiles |

| Density | Low density, lightweight material | Higher density, solid plastic profiles |

| Applications | Insulation, packaging, cushioning, lightweight components | Pipes, sheets, films, tubes, automotive parts |

| Material Types | Polyurethane, polystyrene, polyethylene foams | Polyethylene, polypropylene, PVC, ABS |

| Surface Finish | Porous, textured surface | Smooth, consistent surface |

| Mechanical Strength | Lower strength due to foam structure | Higher tensile and impact strength |

| Cost | Generally lower due to less material use | Higher, tied to raw material and process energy |

| Production Speed | Moderate, dependent on foaming agents | High, continuous extrusion process |

Introduction to Plastic Foaming and Plastic Extrusion

Plastic foaming introduces gas into the polymer matrix, creating a lightweight cellular structure that reduces material usage and enhances insulation properties. Plastic extrusion involves forcing molten plastic through a shaped die to produce continuous profiles with uniform cross-sections, commonly used for pipes, sheets, and films. Both processes optimize plastic performance for specific applications by altering material density and form.

Overview of Plastic Foaming Process

Plastic foaming involves introducing a gas or chemical blowing agent into the polymer matrix, creating a cellular structure that reduces density and enhances insulation properties. This process can be achieved through physical methods, such as gas injection, or chemical methods involving blowing agents that decompose under heat, producing gas. The resulting foamed plastics exhibit improved thermal insulation, impact resistance, and material efficiency compared to solid extruded plastics.

Fundamentals of Plastic Extrusion Technology

Plastic extrusion technology involves melting raw plastic materials and forcing them through a shaped die to create continuous profiles with consistent cross-sections, essential for manufacturing pipes, sheets, and films. Unlike plastic foaming, which introduces gas to create cellular structures for lightweight and insulating properties, extrusion focuses on producing dense, uniform products with precise dimensions. Mastery of temperature control, screw design, and extrusion speed is fundamental in optimizing material flow and product quality in plastic extrusion.

Key Differences Between Plastic Foaming and Extrusion

Plastic foaming involves introducing gas or blowing agents into the polymer matrix to create a cellular structure, resulting in lightweight and insulating materials. Plastic extrusion forces melted plastic through a die to form continuous shapes, emphasizing uniformity and precision in product dimensions. Key differences include foaming's focus on reduced density and thermal insulation versus extrusion's capability for detailed, high-strength profiles and components.

Material Requirements for Foaming vs Extrusion

Plastic foaming demands polymers with specific gas permeability and cell nucleation properties to enable uniform bubble formation, often requiring additives like blowing agents and stabilizers. In contrast, plastic extrusion emphasizes melt flow index and thermal stability to ensure smooth continuous shaping, with polymers needing consistent viscosity under heat and shear. Material selection for foaming prioritizes cellular structure control, whereas extrusion materials focus on mechanical strength and dimensional accuracy.

Applications of Foamed Plastics

Foamed plastics are widely used in packaging, insulation, and automotive components due to their lightweight and excellent thermal insulation properties. These materials are ideal for cushioning fragile items, providing soundproofing, and enhancing energy efficiency in construction. Compared to plastic extrusion, foamed plastics uniquely offer enhanced shock absorption and reduced material consumption, making them cost-effective for diverse industrial applications.

Common Uses of Extruded Plastics

Extruded plastics are widely used in manufacturing pipes, tubing, and sheets due to their consistent cross-sectional profiles and structural integrity. Common applications include automotive parts, electrical cable insulation, and packaging materials, where durability and precision are essential. The extrusion process enables continuous production, making it ideal for large-scale fabrication of plastic components with uniform thickness and strength.

Advantages and Limitations of Plastic Foaming

Plastic foaming offers advantages such as reduced material density, enhanced thermal insulation, and improved cushioning properties, making it ideal for packaging and lightweight applications. However, limitations include lower mechanical strength compared to solid extruded plastics, increased production complexity, and potential challenges in achieving uniform cell structure. These factors require careful consideration when selecting foamed plastics for structural or high-load applications.

Pros and Cons of Plastic Extrusion Methods

Plastic extrusion offers high production efficiency and versatility in creating continuous shapes with consistent cross-sections, making it ideal for manufacturing pipes, profiles, and films. The method provides excellent dimensional accuracy and material uniformity but can be limited by high initial equipment costs and reduced flexibility for complex geometries compared to foaming processes. Extrusion tends to produce denser products with better mechanical properties, whereas foaming allows for lightweight, porous structures but may compromise strength and surface finish.

Choosing Between Plastic Foaming and Extrusion for Manufacturing

Choosing between plastic foaming and extrusion hinges on product requirements such as density, flexibility, and structural integrity. Plastic foaming introduces gas into the polymer matrix, creating lightweight, insulated materials ideal for packaging and cushioning applications. Plastic extrusion forces molten plastic through a die to produce continuous shapes with high strength and durability, suitable for pipes, films, and profiles.

Plastic Foaming vs Plastic Extrusion Infographic

materialdif.com

materialdif.com