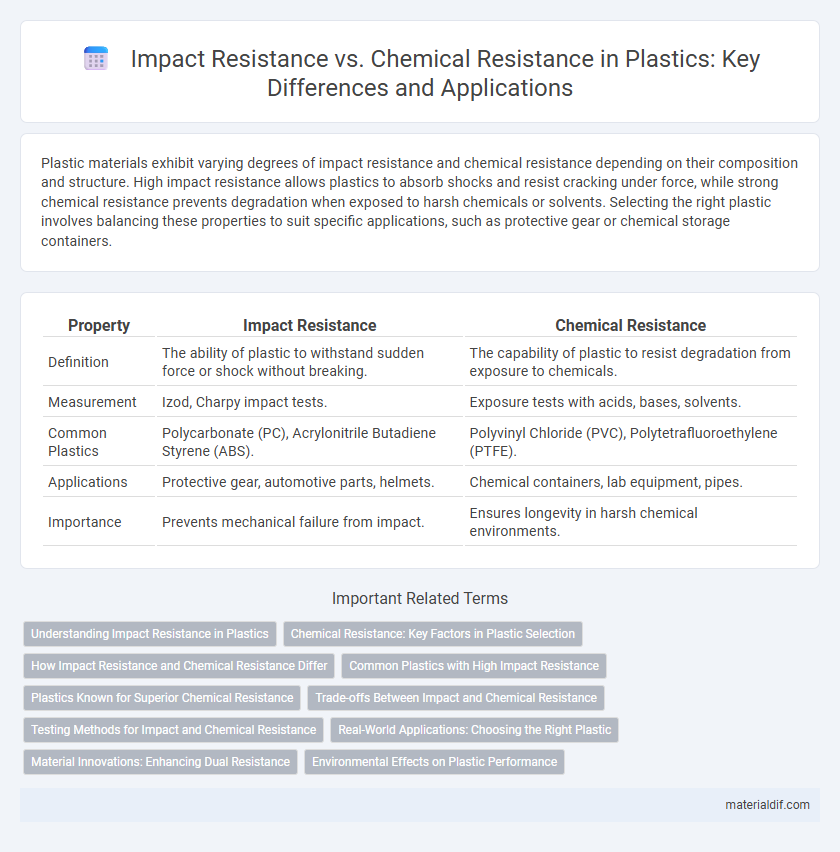

Plastic materials exhibit varying degrees of impact resistance and chemical resistance depending on their composition and structure. High impact resistance allows plastics to absorb shocks and resist cracking under force, while strong chemical resistance prevents degradation when exposed to harsh chemicals or solvents. Selecting the right plastic involves balancing these properties to suit specific applications, such as protective gear or chemical storage containers.

Table of Comparison

| Property | Impact Resistance | Chemical Resistance |

|---|---|---|

| Definition | The ability of plastic to withstand sudden force or shock without breaking. | The capability of plastic to resist degradation from exposure to chemicals. |

| Measurement | Izod, Charpy impact tests. | Exposure tests with acids, bases, solvents. |

| Common Plastics | Polycarbonate (PC), Acrylonitrile Butadiene Styrene (ABS). | Polyvinyl Chloride (PVC), Polytetrafluoroethylene (PTFE). |

| Applications | Protective gear, automotive parts, helmets. | Chemical containers, lab equipment, pipes. |

| Importance | Prevents mechanical failure from impact. | Ensures longevity in harsh chemical environments. |

Understanding Impact Resistance in Plastics

Impact resistance in plastics refers to the material's ability to withstand sudden forces or shocks without fracturing, making it crucial for applications exposed to mechanical stress. This property depends on the polymer's molecular structure, including factors like crystallinity and chain flexibility, which influence energy absorption during impact. Understanding impact resistance is essential for selecting plastics in automotive parts, protective gear, and packaging where durability against drops or collisions is required.

Chemical Resistance: Key Factors in Plastic Selection

Chemical resistance in plastics depends heavily on polymer composition, molecular structure, and the presence of additives, which determine how well the material withstands exposure to acids, bases, solvents, and other chemicals. Selecting plastics with high chemical resistance, such as PTFE, PVC, or HDPE, is essential for applications involving harsh chemicals to prevent degradation, swelling, or cracking. Understanding temperature effects and chemical concentration helps optimize plastic selection to ensure long-term durability and performance in corrosive environments.

How Impact Resistance and Chemical Resistance Differ

Impact resistance refers to a material's ability to withstand mechanical shocks or sudden forces without cracking or breaking, commonly measured by tests such as Izod or Charpy impact tests. Chemical resistance indicates a material's ability to resist degradation or corrosion when exposed to various chemicals, acids, or solvents, often determined through immersion or exposure tests. While impact resistance focuses on physical toughness under stress, chemical resistance emphasizes molecular stability and durability against chemical attacks.

Common Plastics with High Impact Resistance

Polycarbonate, ABS, and nylon are common plastics known for their high impact resistance, making them ideal for applications requiring durability under stress. While polycarbonate also offers moderate chemical resistance, ABS and nylon may degrade when exposed to certain chemicals, highlighting the importance of material selection based on environmental exposure. Understanding the trade-offs between impact resistance and chemical resistance ensures optimal performance in demanding industrial and consumer applications.

Plastics Known for Superior Chemical Resistance

Plastics such as PTFE (polytetrafluoroethylene), PVDF (polyvinylidene fluoride), and HDPE (high-density polyethylene) are renowned for their superior chemical resistance, making them ideal for handling harsh acids, bases, and solvents in industrial applications. While impact resistance is crucial for structural durability, these materials excel by maintaining integrity against corrosive chemicals, minimizing degradation and extending service life. Selecting plastics with high chemical resistance ensures reliability in environments where exposure to aggressive substances would otherwise compromise material performance.

Trade-offs Between Impact and Chemical Resistance

Plastics with high impact resistance, such as polycarbonate and ABS, often sacrifice chemical resistance due to their amorphous molecular structure. Conversely, materials like PTFE and HDPE exhibit excellent chemical resistance but tend to have lower impact strength, limiting their use in high-stress applications. Selecting the right plastic requires balancing these trade-offs based on the specific environmental stressors and mechanical demands of the intended application.

Testing Methods for Impact and Chemical Resistance

Testing methods for impact resistance in plastics often include the Charpy and Izod impact tests, which measure the material's ability to absorb energy during sudden force application. Chemical resistance evaluations involve exposing plastic samples to various solvents, acids, or bases under controlled conditions to observe changes in weight, strength, or appearance. Standardized procedures such as ASTM D256 for impact testing and ASTM D543 for chemical resistance ensure consistent and comparable results across different plastic materials.

Real-World Applications: Choosing the Right Plastic

Impact resistance and chemical resistance are critical factors when selecting plastics for real-world applications such as automotive parts, packaging, and industrial components. Polycarbonate excels in impact resistance, making it ideal for protective gear and safety equipment, while polyethylene offers superior chemical resistance, suitable for containers exposed to harsh solvents and acids. Engineers often balance these properties by selecting specialized polymers or composites tailored to the environmental stresses and durability requirements of the specific use case.

Material Innovations: Enhancing Dual Resistance

Recent material innovations in plastics, such as the incorporation of nanocomposites and advanced polymer blends, significantly enhance both impact resistance and chemical resistance. These engineered plastics demonstrate improved durability and longevity in harsh environments by resisting mechanical shocks while maintaining stability against corrosive substances. Enhanced dual resistance properties optimize performance in aerospace, automotive, and chemical processing industries, ensuring safety and reducing maintenance costs.

Environmental Effects on Plastic Performance

Environmental factors such as temperature fluctuations, UV exposure, and humidity significantly influence the impact resistance and chemical resistance of plastics. High temperatures can cause plastics to become brittle, reducing their ability to absorb impacts, while UV radiation may degrade polymer chains, impairing chemical resistance by increasing susceptibility to solvents and corrosive agents. Moisture and chemical exposure further alter plastic properties by promoting swelling, hydrolysis, or oxidation, ultimately affecting the durability and performance of plastic materials in various applications.

Impact Resistance vs Chemical Resistance Infographic

materialdif.com

materialdif.com