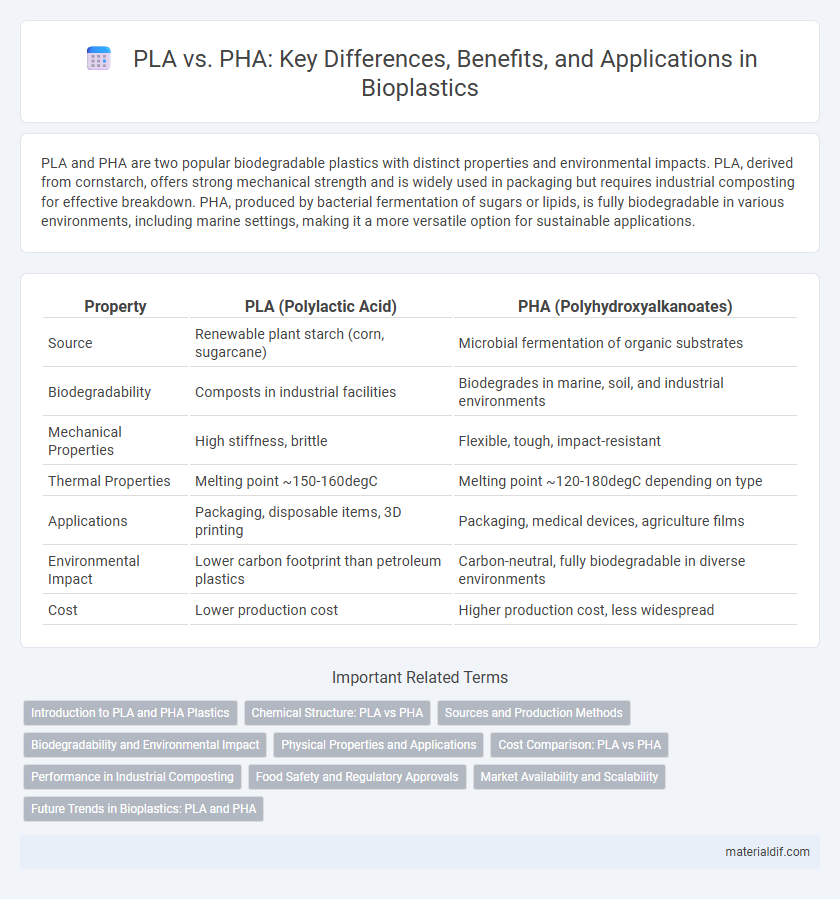

PLA and PHA are two popular biodegradable plastics with distinct properties and environmental impacts. PLA, derived from cornstarch, offers strong mechanical strength and is widely used in packaging but requires industrial composting for effective breakdown. PHA, produced by bacterial fermentation of sugars or lipids, is fully biodegradable in various environments, including marine settings, making it a more versatile option for sustainable applications.

Table of Comparison

| Property | PLA (Polylactic Acid) | PHA (Polyhydroxyalkanoates) |

|---|---|---|

| Source | Renewable plant starch (corn, sugarcane) | Microbial fermentation of organic substrates |

| Biodegradability | Composts in industrial facilities | Biodegrades in marine, soil, and industrial environments |

| Mechanical Properties | High stiffness, brittle | Flexible, tough, impact-resistant |

| Thermal Properties | Melting point ~150-160degC | Melting point ~120-180degC depending on type |

| Applications | Packaging, disposable items, 3D printing | Packaging, medical devices, agriculture films |

| Environmental Impact | Lower carbon footprint than petroleum plastics | Carbon-neutral, fully biodegradable in diverse environments |

| Cost | Lower production cost | Higher production cost, less widespread |

Introduction to PLA and PHA Plastics

PLA (polylactic acid) is a biodegradable plastic derived from renewable resources such as corn starch or sugarcane, widely used in packaging and disposable items due to its compostability and ease of processing. PHA (polyhydroxyalkanoates) is a family of biodegradable polyesters produced by microbial fermentation of sugars or lipids, notable for their versatility and high performance in medical, agricultural, and packaging applications. Both PLA and PHA offer sustainable alternatives to petrochemical plastics, with PLA favored for its cost-effectiveness and PHA for its superior biodegradability in marine environments.

Chemical Structure: PLA vs PHA

PLA (Polylactic Acid) is a polyester derived from lactic acid monomers containing repeating ester groups with a simple linear backbone, making it more crystalline and brittle. PHA (Polyhydroxyalkanoates) consists of hydroxy fatty acid monomers with a variable side chain length, resulting in a more diverse and flexible polymer structure. The chemical structure of PLA leads to higher tensile strength but lower elasticity, while PHA's structure provides greater biodegradability and flexibility in various applications.

Sources and Production Methods

PLA (Polylactic Acid) is derived primarily from renewable starch sources such as corn, sugarcane, or cassava using fermentation followed by polymerization processes. PHA (Polyhydroxyalkanoates) is naturally produced by bacterial fermentation of organic substrates, including waste oils and sugars, accumulating intracellularly as energy storage compounds. While PLA relies on agricultural crops for feedstock, PHA production utilizes a broader range of feedstocks and involves microbial synthesis under controlled fermentation conditions.

Biodegradability and Environmental Impact

PLA (Polylactic Acid) biodegrades effectively under industrial composting conditions but breaks down slowly in natural environments, limiting its overall environmental benefit. PHA (Polyhydroxyalkanoates) demonstrates superior biodegradability across diverse ecosystems, including marine and soil environments, making it a more sustainable plastic alternative. Environmental impact assessments show PHA generates fewer greenhouse gases and less toxic residue during degradation compared to PLA, reinforcing its position as a greener bioplastic solution.

Physical Properties and Applications

PLA exhibits higher rigidity and tensile strength with a melting point around 150-160degC, making it suitable for packaging and disposable tableware. PHA offers superior flexibility, biodegradability in marine environments, and thermal resistance up to 170degC, ideal for agricultural films and medical implants. Both bioplastics serve niche markets where specific mechanical properties and eco-friendly disposal are critical.

Cost Comparison: PLA vs PHA

PLA (Polylactic Acid) generally offers lower production costs compared to PHA (Polyhydroxyalkanoates) due to its simpler fermentation and polymerization processes, making it more economically viable for large-scale applications. PHA, while biodegradable and compostable, incurs higher manufacturing expenses stemming from complex microbial synthesis and costly feedstocks. The cost disparity significantly influences the choice of bioplastic, with PLA favored in cost-sensitive markets and PHA preferred where enhanced biodegradability justifies the premium price.

Performance in Industrial Composting

PLA (Polylactic Acid) and PHA (Polyhydroxyalkanoates) both show promising performance in industrial composting environments, with PLA typically breaking down within 1 to 3 months under controlled conditions of 58-60degC and high humidity. PHA exhibits superior biodegradability, often degrading completely within 45 to 90 days due to its microbial origin, and it can compost effectively even in less optimized conditions compared to PLA. The faster and more consistent composting behavior of PHA makes it a preferred choice for applications requiring reliable end-of-life management in industrial composting facilities.

Food Safety and Regulatory Approvals

PLA (Polylactic Acid) and PHA (Polyhydroxyalkanoates) are both biodegradable plastics widely used in food packaging, but PHA offers superior food safety due to its natural microbial fermentation origin and enhanced resistance to microbial contamination. Regulatory approvals for PLA are well-established with FDA and EFSA recognition for food contact applications, while PHA is gaining increasing approval worldwide, supported by its biodegradability and compostability credentials under standards such as ASTM D6400 and EN 13432. Both materials meet strict migration limits essential for food safety, but PHA's broader spectrum of regulatory acceptance positions it as a safer alternative in applications requiring stringent compliance.

Market Availability and Scalability

PLA dominates the market with widespread availability due to its cost-effective production from renewable resources like corn starch, making it a preferred choice in packaging and disposable items. PHA, though biocompatible and biodegradable, remains less commercially accessible because of higher production costs and limited large-scale manufacturing facilities. Scalability challenges hinder PHA expansion, whereas PLA benefits from established industrial-scale processing and supply chains.

Future Trends in Bioplastics: PLA and PHA

PLA and PHA represent two of the most promising bioplastics driving innovation in sustainable materials, with global demand for PLA projected to grow at a CAGR of over 15% by 2030 due to its affordability and biodegradability. PHA, known for its superior compostability and production from renewable resources, is gaining traction in high-value applications such as medical devices and packaging, supported by advancements in microbial fermentation technologies. Future trends emphasize the integration of PLA and PHA in circular economy models, leveraging improved bioprocessing techniques and the development of hybrid bioplastics to enhance material performance and environmental impact.

PLA vs PHA Infographic

materialdif.com

materialdif.com