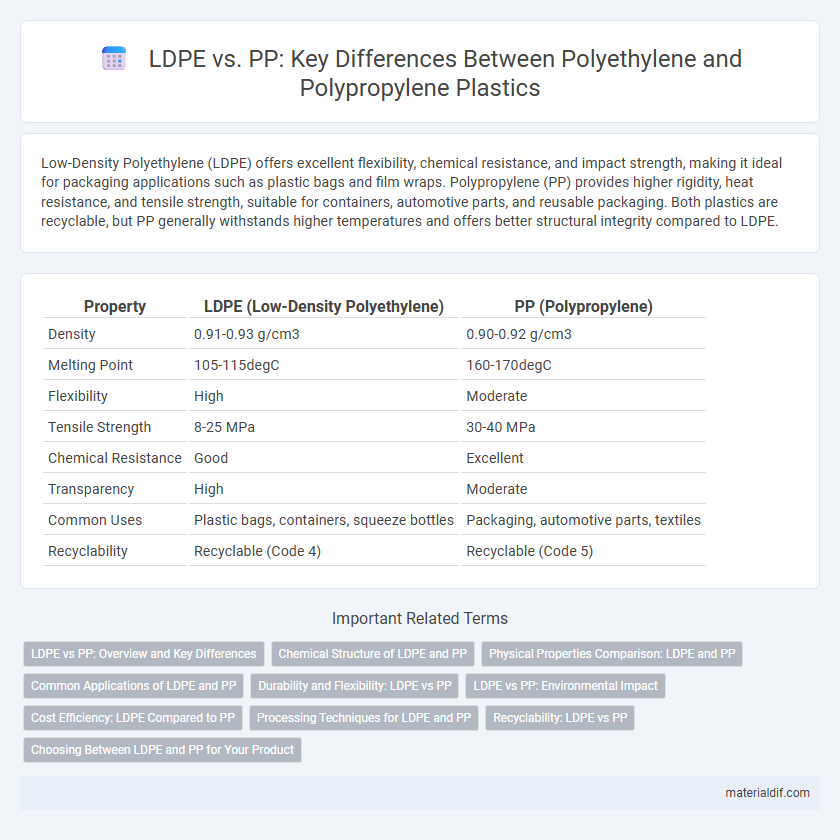

Low-Density Polyethylene (LDPE) offers excellent flexibility, chemical resistance, and impact strength, making it ideal for packaging applications such as plastic bags and film wraps. Polypropylene (PP) provides higher rigidity, heat resistance, and tensile strength, suitable for containers, automotive parts, and reusable packaging. Both plastics are recyclable, but PP generally withstands higher temperatures and offers better structural integrity compared to LDPE.

Table of Comparison

| Property | LDPE (Low-Density Polyethylene) | PP (Polypropylene) |

|---|---|---|

| Density | 0.91-0.93 g/cm3 | 0.90-0.92 g/cm3 |

| Melting Point | 105-115degC | 160-170degC |

| Flexibility | High | Moderate |

| Tensile Strength | 8-25 MPa | 30-40 MPa |

| Chemical Resistance | Good | Excellent |

| Transparency | High | Moderate |

| Common Uses | Plastic bags, containers, squeeze bottles | Packaging, automotive parts, textiles |

| Recyclability | Recyclable (Code 4) | Recyclable (Code 5) |

LDPE vs PP: Overview and Key Differences

Low-Density Polyethylene (LDPE) and Polypropylene (PP) are widely used thermoplastics with distinct properties and applications. LDPE offers high flexibility, excellent impact resistance, and superior transparency, making it ideal for packaging films and containers, whereas PP provides greater rigidity, higher melting point, and better chemical resistance suitable for automotive parts and household goods. The key differences center on their molecular structure, mechanical strength, thermal tolerance, and suitability for specific manufacturing processes like injection molding versus film extrusion.

Chemical Structure of LDPE and PP

Low-Density Polyethylene (LDPE) features a highly branched chemical structure with numerous short and long side chains, which reduces intermolecular forces and results in a less dense, more flexible polymer. Polypropylene (PP) has a more regular, linear backbone with methyl group side chains attached to every other carbon atom, providing greater crystallinity and rigidity. The distinct branching in LDPE versus the stereoregular structure of PP influences their physical properties, making LDPE more pliable and PP more durable.

Physical Properties Comparison: LDPE and PP

Low-Density Polyethylene (LDPE) exhibits lower tensile strength and higher flexibility compared to Polypropylene (PP), making LDPE more suitable for applications requiring pliability such as plastic bags and film wrap. PP has a higher melting point around 160-170degC and greater rigidity, which contributes to its widespread use in automotive parts, food containers, and textiles. Both materials offer excellent chemical resistance, but LDPE stands out for its impact resistance, while PP provides superior fatigue resistance and stiffness.

Common Applications of LDPE and PP

Low-Density Polyethylene (LDPE) is commonly used in flexible packaging such as plastic bags, film wraps, and containers due to its excellent clarity and flexibility. Polypropylene (PP) is favored for rigid packaging, automotive parts, and consumer goods because of its higher melting point and strength. Both LDPE and PP play vital roles in everyday products, with LDPE suited for lightweight, flexible applications and PP for durable, heat-resistant uses.

Durability and Flexibility: LDPE vs PP

Low-Density Polyethylene (LDPE) offers superior flexibility and impact resistance, making it suitable for applications requiring bendability and stress tolerance. Polypropylene (PP) exhibits higher durability with better resistance to fatigue, heat, and chemical exposure, ideal for rigid and long-lasting products. The choice between LDPE and PP depends on the balance needed between flexibility and strength in the intended application.

LDPE vs PP: Environmental Impact

Low-Density Polyethylene (LDPE) generally has a lower environmental impact compared to Polypropylene (PP) due to its higher recyclability rate and lower energy consumption during production. LDPE's ability to be more easily recycled reduces landfill waste and minimizes pollution, whereas PP, despite its durability, presents greater challenges in recycling processes. The environmental footprint of LDPE is further decreased by its biodegradability potential in certain conditions, unlike PP, which persists longer in ecosystems.

Cost Efficiency: LDPE Compared to PP

LDPE offers lower raw material and production costs compared to PP, making it a cost-efficient option for applications requiring flexibility and impact resistance. The processing temperatures for LDPE are generally lower, reducing energy consumption and manufacturing expenses. However, PP provides better mechanical strength and chemical resistance, which can justify its higher cost in specialized uses.

Processing Techniques for LDPE and PP

LDPE (Low-Density Polyethylene) is processed primarily through extrusion, blow molding, and injection molding due to its high flexibility and low melting point, enabling easy shaping into films and flexible packaging. PP (Polypropylene) utilizes injection molding, extrusion, and thermoforming, excelling in producing rigid containers and automotive parts thanks to its higher melting point and stiffness. Both polymers require specific temperature control during processing to optimize mechanical properties and prevent degradation.

Recyclability: LDPE vs PP

LDPE (Low-Density Polyethylene) and PP (Polypropylene) differ significantly in recyclability due to their chemical structures and common applications. LDPE is widely recycled through processes like mechanical recycling but often faces challenges due to contamination and collection inefficiencies, leading to lower recycling rates compared to PP. PP, characterized by higher melting points and durability, enjoys more established recycling streams and better market demand for recycled pellets, promoting greater circularity in packaging and automotive sectors.

Choosing Between LDPE and PP for Your Product

Choosing between LDPE (Low-Density Polyethylene) and PP (Polypropylene) depends on the product requirements such as flexibility, durability, and temperature resistance. LDPE offers excellent flexibility and impact resistance, making it ideal for products like plastic bags and flexible tubing, while PP provides higher mechanical strength and thermal stability, suitable for automotive parts and food containers. Evaluating the end-use environment and processing methods helps determine whether LDPE or PP best meets performance and cost-efficiency goals.

LDPE vs PP Infographic

materialdif.com

materialdif.com