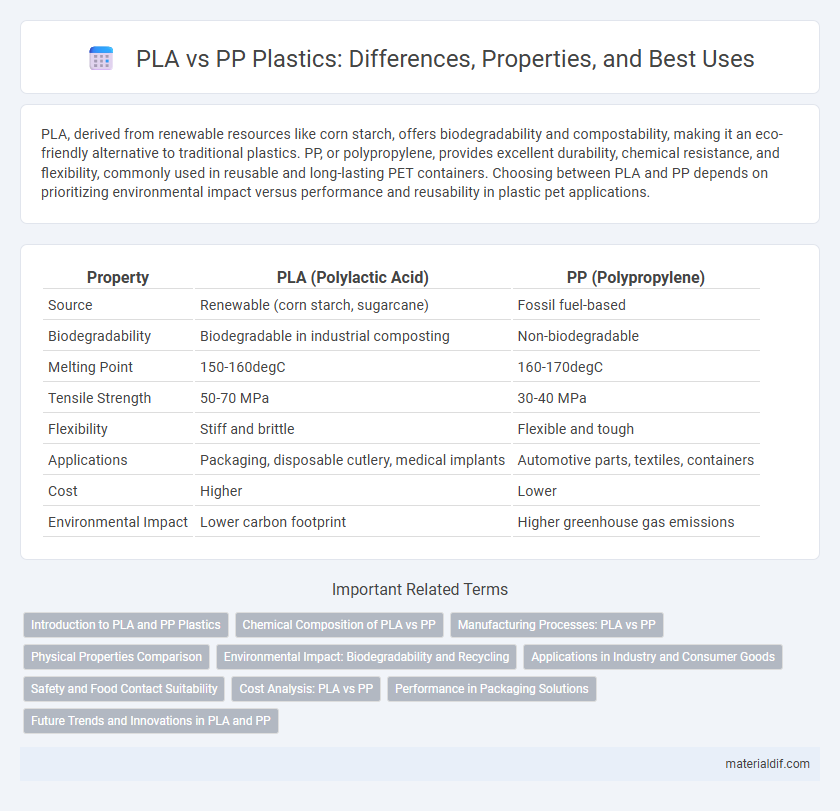

PLA, derived from renewable resources like corn starch, offers biodegradability and compostability, making it an eco-friendly alternative to traditional plastics. PP, or polypropylene, provides excellent durability, chemical resistance, and flexibility, commonly used in reusable and long-lasting PET containers. Choosing between PLA and PP depends on prioritizing environmental impact versus performance and reusability in plastic pet applications.

Table of Comparison

| Property | PLA (Polylactic Acid) | PP (Polypropylene) |

|---|---|---|

| Source | Renewable (corn starch, sugarcane) | Fossil fuel-based |

| Biodegradability | Biodegradable in industrial composting | Non-biodegradable |

| Melting Point | 150-160degC | 160-170degC |

| Tensile Strength | 50-70 MPa | 30-40 MPa |

| Flexibility | Stiff and brittle | Flexible and tough |

| Applications | Packaging, disposable cutlery, medical implants | Automotive parts, textiles, containers |

| Cost | Higher | Lower |

| Environmental Impact | Lower carbon footprint | Higher greenhouse gas emissions |

Introduction to PLA and PP Plastics

PLA (Polylactic Acid) is a biodegradable, bio-based plastic derived from renewable resources like corn starch and sugarcane, widely used for eco-friendly packaging and disposable items. PP (Polypropylene) is a versatile thermoplastic polymer known for its excellent chemical resistance, durability, and high melting point, making it ideal for automotive parts, consumer goods, and food containers. PLA offers compostability and reduced carbon footprint, whereas PP provides superior mechanical strength and heat resistance for heavy-duty applications.

Chemical Composition of PLA vs PP

Polylactic acid (PLA) is a biodegradable thermoplastic derived from renewable resources like corn starch, consisting primarily of repeating units of lactic acid with ester linkages (-COO-), which contribute to its biodegradability and compostability. Polypropylene (PP) is a synthetic polymer made from the polymerization of propylene monomers, featuring a hydrocarbon backbone with methyl groups (-CH3) attached to alternating carbon atoms, resulting in a non-polar, hydrophobic material with high chemical resistance. The ester bonds in PLA make it susceptible to hydrolytic degradation, whereas the saturated hydrocarbon structure of PP provides greater chemical stability and resistance to environmental degradation.

Manufacturing Processes: PLA vs PP

PLA (Polylactic Acid) is derived from renewable resources such as corn starch through fermentation and polymerization, utilizing extrusion and injection molding techniques that accommodate its lower melting point of around 160-180degC. PP (Polypropylene), a petroleum-based polymer, undergoes energy-intensive manufacturing processes including polymerization via Ziegler-Natta catalysts and is compatible with high-temperature processing methods like injection molding and blow molding due to its melting point of approximately 160-170degC. The processing of PLA demands precise temperature control to avoid degradation, whereas PP's robust thermal resistance allows for greater manufacturing flexibility and widespread industrial application.

Physical Properties Comparison

PLA (Polylactic Acid) exhibits higher tensile strength and stiffness compared to PP (Polypropylene), making it more rigid but less impact-resistant. PP offers superior flexibility, higher elongation at break, and better resistance to environmental stress cracking, enhancing its durability in dynamic applications. Thermal stability is greater in PP, with a melting point around 160degC compared to PLA's lower thermal resistance near 150degC, influencing their suitability for heat-exposed uses.

Environmental Impact: Biodegradability and Recycling

PLA (Polylactic Acid) is a biodegradable plastic derived from renewable resources like corn starch, breaking down under industrial composting conditions within months, thus reducing landfill accumulation. PP (Polypropylene) is a petroleum-based plastic known for its durability and resistance to degradation, often remaining in the environment for centuries and posing significant recycling challenges due to contamination and sorting issues. While PLA offers environmental benefits through lower carbon emissions and biodegradability, its recycling infrastructure is limited compared to PP, which is widely recycled but contributes to long-term environmental pollution when improperly managed.

Applications in Industry and Consumer Goods

Polylactic Acid (PLA) is extensively used in biodegradable packaging, disposable tableware, and medical implants due to its compostability and biocompatibility, while Polypropylene (PP) dominates in automotive parts, reusable containers, and textiles for its durability and chemical resistance. PLA's applications in consumer goods emphasize eco-friendly alternatives, especially in food packaging and 3D printing filaments. PP's industrial use thrives in manufacturing processes demanding high impact resistance and thermal stability, such as in piping systems and household appliances.

Safety and Food Contact Suitability

Polylactic Acid (PLA) is a biodegradable, food-safe plastic derived from renewable resources such as corn starch, offering excellent safety for food contact due to its non-toxic nature and compliance with FDA and EU regulations. Polypropylene (PP) is a durable, heat-resistant plastic commonly used in food packaging, approved for repeated food contact and known for its chemical resistance and low risk of leaching harmful substances. While PLA provides an eco-friendly alternative with safe disposal benefits, PP remains preferable for applications requiring higher temperature tolerance and long-term food storage safety.

Cost Analysis: PLA vs PP

PLA (Polylactic Acid) generally incurs higher production costs compared to PP (Polypropylene) due to its renewable raw materials and more complex manufacturing process. PP offers cost advantages with lower raw material prices and established mass production techniques, making it more economically viable for large-scale applications. Despite PLA's environmental benefits, PP remains the preferred choice where cost efficiency is the primary factor.

Performance in Packaging Solutions

PLA (Polylactic Acid) offers excellent clarity and a biodegradable profile, making it suitable for eco-friendly packaging with moderate barrier properties against moisture and oxygen. PP (Polypropylene) exhibits superior mechanical strength, high thermal resistance, and excellent moisture barrier capabilities, ideal for packaging that requires durability and extended shelf life. The choice between PLA and PP depends on the packaging requirements, balancing sustainability goals with performance criteria such as durability and preservation.

Future Trends and Innovations in PLA and PP

Future trends in PLA emphasize biodegradable enhancements and renewable feedstock sourcing to boost sustainability and reduce environmental impact, with innovations in blending PLA with other biopolymers for improved mechanical properties and heat resistance. PP advancements focus on lightweight composite formulations and chemical recycling technologies to extend lifecycle and promote circular economy practices. Emerging research on bio-based PP and multifunctional coatings aims to combine durability with eco-friendly attributes, positioning both polymers for diversified applications in packaging, automotive, and consumer goods sectors.

PLA vs PP Infographic

materialdif.com

materialdif.com