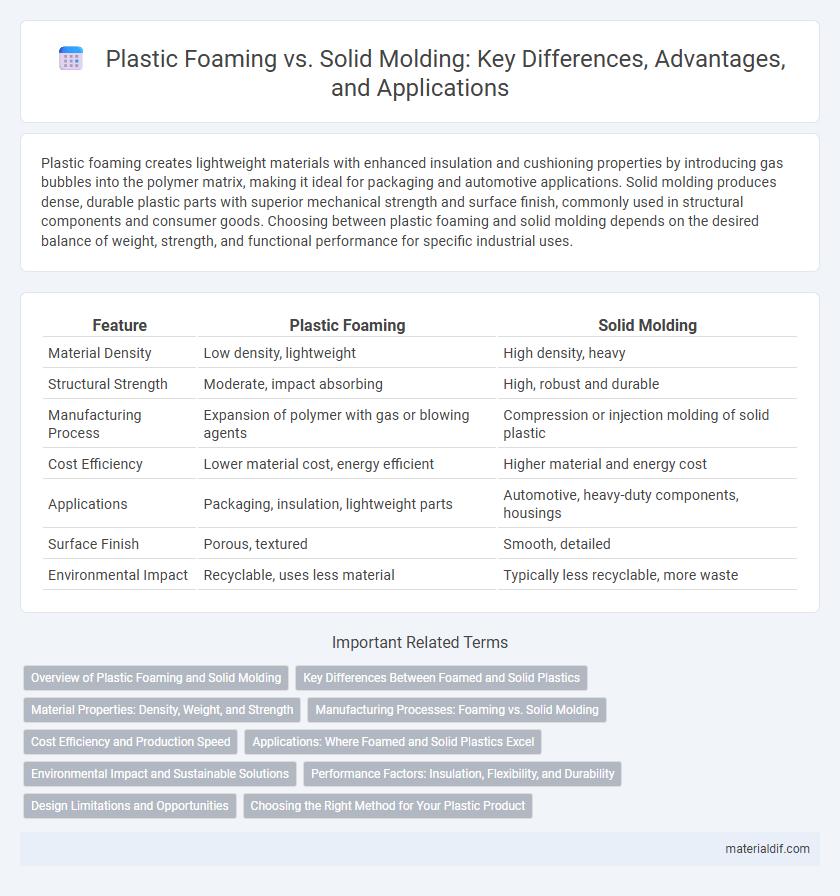

Plastic foaming creates lightweight materials with enhanced insulation and cushioning properties by introducing gas bubbles into the polymer matrix, making it ideal for packaging and automotive applications. Solid molding produces dense, durable plastic parts with superior mechanical strength and surface finish, commonly used in structural components and consumer goods. Choosing between plastic foaming and solid molding depends on the desired balance of weight, strength, and functional performance for specific industrial uses.

Table of Comparison

| Feature | Plastic Foaming | Solid Molding |

|---|---|---|

| Material Density | Low density, lightweight | High density, heavy |

| Structural Strength | Moderate, impact absorbing | High, robust and durable |

| Manufacturing Process | Expansion of polymer with gas or blowing agents | Compression or injection molding of solid plastic |

| Cost Efficiency | Lower material cost, energy efficient | Higher material and energy cost |

| Applications | Packaging, insulation, lightweight parts | Automotive, heavy-duty components, housings |

| Surface Finish | Porous, textured | Smooth, detailed |

| Environmental Impact | Recyclable, uses less material | Typically less recyclable, more waste |

Overview of Plastic Foaming and Solid Molding

Plastic foaming involves introducing gas bubbles into the polymer matrix to create lightweight, porous materials with enhanced thermal insulation and reduced density. Solid molding, such as injection or compression molding, produces dense, uniform plastic parts with high structural integrity and surface finish. Both methods offer tailored mechanical and physical properties suited for diverse applications ranging from automotive components to packaging.

Key Differences Between Foamed and Solid Plastics

Foamed plastics contain gas bubbles trapped within the polymer matrix, leading to a reduced density and enhanced insulation properties compared to solid plastics, which are dense and non-porous. Solid molding results in products with higher strength, stiffness, and durability, while plastic foaming improves impact absorption and reduces material usage and weight. The cellular structure in foamed plastics significantly affects thermal conductivity and buoyancy, whereas solid molded plastics excel in load-bearing and dimensional stability applications.

Material Properties: Density, Weight, and Strength

Plastic foaming exhibits lower density and weight compared to solid molding, making it ideal for applications requiring lightweight materials. Foamed plastics maintain moderate strength but generally offer reduced mechanical properties relative to solid molded plastics, which provide superior strength and structural integrity. The choice between foamed and solid molding hinges on balancing material density, weight constraints, and the necessary strength for specific industrial applications.

Manufacturing Processes: Foaming vs. Solid Molding

Plastic foaming involves injecting gas or chemical agents into the polymer to create a lightweight, porous structure that enhances insulation and reduces material usage. Solid molding processes such as injection molding or compression molding produce dense, uniform parts with high mechanical strength and dimensional accuracy. Choosing between foaming and solid molding depends on the application's requirements for weight, strength, and thermal performance.

Cost Efficiency and Production Speed

Plastic foaming reduces material usage and energy consumption, resulting in lower production costs compared to solid molding. Solid molding offers faster cycle times for high-volume production but requires more raw material and higher energy input. Cost efficiency depends on product design and production scale, with foaming favored for lightweight, complex shapes and solid molding preferred for durability and rapid batch output.

Applications: Where Foamed and Solid Plastics Excel

Foamed plastics excel in applications requiring lightweight materials with excellent insulation properties, such as packaging, automotive components, and thermal insulation panels. Solid molding plastics are preferred for high-strength, durable products like household appliances, automotive parts, and industrial equipment where structural integrity is critical. The choice between foamed and solid plastics depends on balancing weight reduction, insulation needs, and mechanical strength requirements in specific industries.

Environmental Impact and Sustainable Solutions

Plastic foaming generates lightweight materials with lower resource consumption but often involves blowing agents that contribute to greenhouse gas emissions, posing environmental challenges. Solid molding uses denser, more stable plastics, resulting in less off-gassing but higher material usage and energy consumption during production. Sustainable solutions include developing bio-based foaming agents and recyclable solid-molded plastics to reduce carbon footprint and enhance circularity in plastic manufacturing.

Performance Factors: Insulation, Flexibility, and Durability

Plastic foaming offers superior insulation due to its cellular structure that traps air, enhancing thermal resistance compared to solid molding. Flexibility in foam plastics is typically greater, allowing for better shock absorption and cushioning, whereas solid molded plastics provide higher structural rigidity. Durability varies as solid molding excels in impact resistance and load-bearing capacity, while foamed plastics may degrade faster under mechanical stress but provide resilience in lightweight applications.

Design Limitations and Opportunities

Plastic foaming offers the advantage of lightweight structures with enhanced insulation properties, but it faces design limitations such as reduced mechanical strength and less detailed surface finishes compared to solid molding. Solid molding enables precise, complex shapes and high durability, making it ideal for load-bearing applications, yet it can result in heavier products and higher material costs. Choosing between plastic foaming and solid molding depends on balancing design priorities like strength, weight, and cost-efficiency in manufacturing.

Choosing the Right Method for Your Plastic Product

Plastic foaming creates lightweight, insulating materials by introducing gas bubbles into the polymer matrix, ideal for packaging and cushioning applications requiring flexibility and reduced density. Solid molding, including injection or compression molding, produces dense, rigid products with high structural integrity, suitable for durable components and precise, detailed designs. Selecting between foaming and solid molding depends on factors such as desired product strength, weight constraints, thermal insulation properties, and cost-effectiveness in the manufacturing process.

Plastic Foaming vs Solid Molding Infographic

materialdif.com

materialdif.com