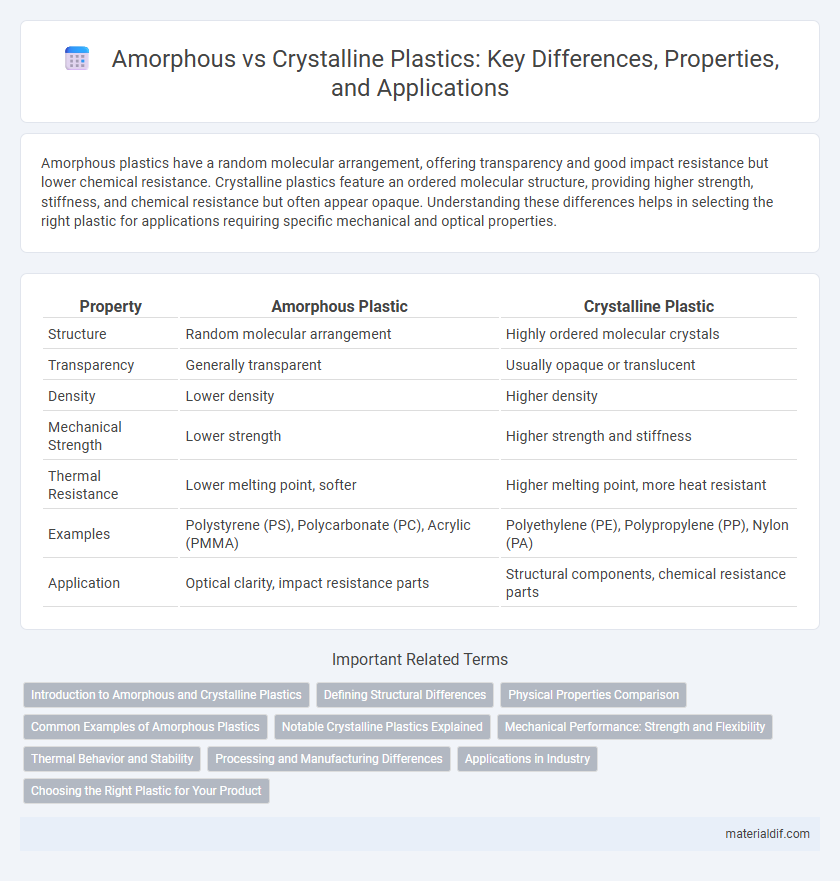

Amorphous plastics have a random molecular arrangement, offering transparency and good impact resistance but lower chemical resistance. Crystalline plastics feature an ordered molecular structure, providing higher strength, stiffness, and chemical resistance but often appear opaque. Understanding these differences helps in selecting the right plastic for applications requiring specific mechanical and optical properties.

Table of Comparison

| Property | Amorphous Plastic | Crystalline Plastic |

|---|---|---|

| Structure | Random molecular arrangement | Highly ordered molecular crystals |

| Transparency | Generally transparent | Usually opaque or translucent |

| Density | Lower density | Higher density |

| Mechanical Strength | Lower strength | Higher strength and stiffness |

| Thermal Resistance | Lower melting point, softer | Higher melting point, more heat resistant |

| Examples | Polystyrene (PS), Polycarbonate (PC), Acrylic (PMMA) | Polyethylene (PE), Polypropylene (PP), Nylon (PA) |

| Application | Optical clarity, impact resistance parts | Structural components, chemical resistance parts |

Introduction to Amorphous and Crystalline Plastics

Amorphous plastics, such as polystyrene and polycarbonate, have a random molecular arrangement resulting in transparency and impact resistance, while crystalline plastics like polyethylene and polypropylene feature an ordered molecular structure that provides higher chemical resistance and strength. The degree of crystallinity significantly influences the mechanical and thermal properties, with amorphous plastics exhibiting lower density and higher flexibility compared to their crystalline counterparts. Understanding the differences in molecular structure is essential for selecting the right plastic type for applications requiring specific durability, clarity, and temperature tolerance.

Defining Structural Differences

Amorphous plastics feature a random, disordered molecular structure, resulting in transparent, flexible materials with low melting points and isotropic mechanical properties. Crystalline plastics possess highly ordered molecular chains that form tightly packed regions, leading to increased density, higher melting points, and enhanced tensile strength. The degree of crystallinity directly influences thermal behavior, chemical resistance, and mechanical performance in both types of plastics.

Physical Properties Comparison

Amorphous plastics exhibit lower density and increased transparency due to their random molecular arrangement, resulting in moderate strength and impact resistance. Crystalline plastics feature tightly packed molecular chains, providing higher density, superior tensile strength, and greater chemical resistance but lower impact resistance and reduced optical clarity. Thermal behavior differs as crystalline plastics have distinct melting points, whereas amorphous plastics soften over a temperature range.

Common Examples of Amorphous Plastics

Common examples of amorphous plastics include polystyrene (PS), polycarbonate (PC), and acrylonitrile butadiene styrene (ABS), known for their transparency and impact resistance. These plastics lack a defined crystalline structure, resulting in enhanced clarity and improved dimensional stability. Their applications range from optical lenses and automotive parts to consumer electronics due to their unique mechanical and thermal properties.

Notable Crystalline Plastics Explained

Notable crystalline plastics include polyethylene (PE), polypropylene (PP), and polyamide (nylon), which exhibit highly ordered molecular structures resulting in enhanced mechanical strength, chemical resistance, and higher melting points. These materials demonstrate superior durability and rigidity compared to amorphous plastics like polystyrene or polycarbonate, making them ideal for applications requiring toughness and thermal stability. Crystalline plastics also feature distinct melting temperatures, enabling precise processing techniques such as injection molding and extrusion in manufacturing.

Mechanical Performance: Strength and Flexibility

Amorphous plastics exhibit superior flexibility and impact resistance due to their irregular molecular arrangement, allowing them to absorb stress without fracturing. Crystalline plastics possess higher mechanical strength and stiffness, resulting from their tightly packed, ordered molecular structure, which enhances load-bearing capacity but reduces flexibility. The choice between amorphous and crystalline plastics depends on required balance between strength and flexibility for specific applications like automotive parts or packaging.

Thermal Behavior and Stability

Amorphous plastics exhibit lower melting points and gradual softening over a broad temperature range due to their irregular molecular structure, resulting in less thermal stability compared to crystalline plastics. Crystalline plastics feature tightly packed polymer chains with distinct melting points, providing higher thermal resistance and improved dimensional stability under heat. These differences influence material selection in applications requiring specific thermal behaviors, such as heat resistance or flexibility.

Processing and Manufacturing Differences

Amorphous plastics, such as polystyrene and polycarbonate, exhibit random molecular arrangements, resulting in lower melting points and easier thermoforming during manufacturing processes like injection molding and extrusion. Crystalline plastics, including polyethylene and polypropylene, feature ordered molecular structures that require higher processing temperatures and longer cooling times to achieve desired mechanical properties, often making manufacturing more energy-intensive. Differences in crystallinity affect cycle times, part shrinkage, and dimensional stability, influencing the selection of processing parameters for optimized production efficiency.

Applications in Industry

Amorphous plastics such as polystyrene (PS) and polycarbonate (PC) are widely used in optical lenses, automotive components, and medical devices due to their transparency and impact resistance. Crystalline plastics like polypropylene (PP) and polyethylene (PE) find extensive applications in packaging, automotive fuel tanks, and industrial containers for their chemical resistance and high tensile strength. The choice between amorphous and crystalline plastics depends on the required mechanical properties, thermal stability, and environmental durability in specific industrial applications.

Choosing the Right Plastic for Your Product

Selecting the right plastic involves understanding the distinctions between amorphous and crystalline plastics, as amorphous plastics such as polystyrene offer transparency and ease of processing, while crystalline plastics like polypropylene provide superior chemical resistance and mechanical strength. Amorphous plastics exhibit random molecular arrangements resulting in higher impact resistance and better dimensional stability, making them ideal for applications requiring clarity and toughness. Crystalline plastics crystallize into ordered structures, yielding higher melting points and rigidity, suitable for products subjected to thermal stress and heavy loads.

Amorphous Plastic vs Crystalline Plastic Infographic

materialdif.com

materialdif.com