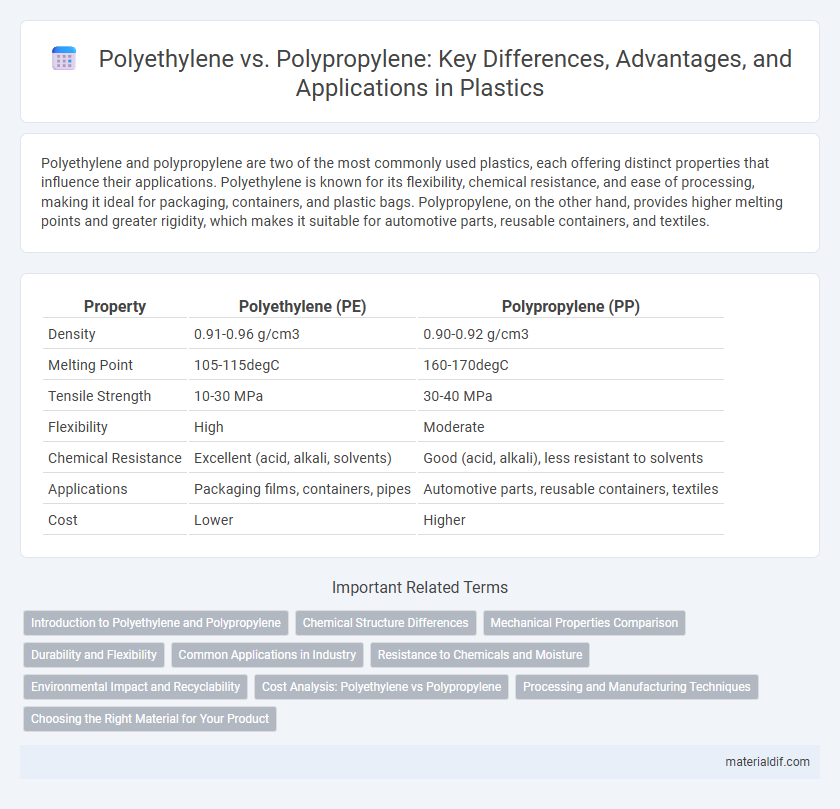

Polyethylene and polypropylene are two of the most commonly used plastics, each offering distinct properties that influence their applications. Polyethylene is known for its flexibility, chemical resistance, and ease of processing, making it ideal for packaging, containers, and plastic bags. Polypropylene, on the other hand, provides higher melting points and greater rigidity, which makes it suitable for automotive parts, reusable containers, and textiles.

Table of Comparison

| Property | Polyethylene (PE) | Polypropylene (PP) |

|---|---|---|

| Density | 0.91-0.96 g/cm3 | 0.90-0.92 g/cm3 |

| Melting Point | 105-115degC | 160-170degC |

| Tensile Strength | 10-30 MPa | 30-40 MPa |

| Flexibility | High | Moderate |

| Chemical Resistance | Excellent (acid, alkali, solvents) | Good (acid, alkali), less resistant to solvents |

| Applications | Packaging films, containers, pipes | Automotive parts, reusable containers, textiles |

| Cost | Lower | Higher |

Introduction to Polyethylene and Polypropylene

Polyethylene is the most widely produced plastic globally, known for its flexibility, chemical resistance, and low cost, making it ideal for packaging, containers, and household goods. Polypropylene offers higher stiffness, heat resistance, and durability, often used in automotive parts, textiles, and reusable containers. Both polyolefins are thermoplastics derived from petroleum, but their structural differences influence applications and mechanical properties significantly.

Chemical Structure Differences

Polyethylene consists of a simple carbon chain with hydrogen atoms attached, characterized by its repeating -CH2- units, which gives it a linear or branched structure depending on the type. Polypropylene features a similar carbon backbone but includes a methyl group (CH3) attached to every other carbon atom, introducing asymmetry and steric hindrance in its molecular structure. This chemical difference influences their thermal properties and crystallinity, with polypropylene generally exhibiting higher melting points and rigidity compared to polyethylene.

Mechanical Properties Comparison

Polyethylene exhibits superior impact resistance and flexibility, making it ideal for applications requiring toughness and elongation, while polypropylene offers higher tensile strength and stiffness suited for structural components. Polypropylene's higher melting point enhances thermal stability compared to polyethylene, which performs better in low-temperature environments due to its lower crystallinity. Mechanical properties such as tensile strength range from 20-40 MPa for polyethylene and 30-70 MPa for polypropylene, highlighting polypropylene's advantage in load-bearing applications.

Durability and Flexibility

Polyethylene offers superior flexibility due to its low-density molecular structure, making it ideal for applications requiring pliability and impact resistance. Polypropylene exhibits higher durability with greater tensile strength and chemical resistance, suitable for products exposed to mechanical stress and harsh environments. Choosing between polyethylene and polypropylene depends on the balance needed between flexibility and long-lasting durability in specific use cases.

Common Applications in Industry

Polyethylene is widely utilized in packaging films, plastic bags, and containers due to its flexibility and moisture resistance, making it essential in the food and consumer goods industries. Polypropylene is favored for automotive parts, reusable containers, and textiles because of its higher melting point and chemical resistance, supporting durability in manufacturing and industrial applications. Both materials play critical roles in their respective sectors, with polyethylene excelling in lightweight, flexible uses and polypropylene dominating in rigid, heat-resistant products.

Resistance to Chemicals and Moisture

Polyethylene exhibits excellent resistance to most acids, bases, and organic solvents, making it highly durable in chemical environments, while polypropylene offers superior resistance to fatigue and higher tolerance to moisture absorption. Polypropylene's crystalline structure provides enhanced chemical stability against alkalis and hydrocarbons compared to polyethylene, yet both materials demonstrate low permeability to water vapor, ensuring effective moisture barriers. For applications requiring extended exposure to harsh chemicals and damp conditions, polypropylene often outperforms polyethylene due to its higher melting point and improved resistance to chemical degradation.

Environmental Impact and Recyclability

Polyethylene and polypropylene differ significantly in environmental impact and recyclability; polyethylene, commonly found in plastic bags and packaging, is recyclable but often contributes to pollution due to low recycling rates. Polypropylene, used in containers and automotive parts, is more durable and has a higher recycling value, making it more sustainable when properly processed. Both plastics require improved waste management strategies to reduce their ecological footprints.

Cost Analysis: Polyethylene vs Polypropylene

Polyethylene generally offers a lower production cost compared to polypropylene, driven by its simpler polymerization process and abundant raw material availability. Polypropylene, while slightly more expensive, provides enhanced chemical resistance and higher melting points, which can justify the premium in applications demanding durability. Cost analysis must consider not only the initial material price but also long-term performance and recyclability factors impacting overall economic efficiency.

Processing and Manufacturing Techniques

Polyethylene (PE) and polypropylene (PP) differ significantly in processing and manufacturing techniques due to their molecular structures; PE is typically processed through extrusion, blow molding, and injection molding, benefiting from its lower melting point and flexibility. Polypropylene's higher melting point enables it to withstand more rigorous thermal processes, making it ideal for injection molding, thermoforming, and film production with excellent fatigue resistance. Both polymers require specific temperature controls and cooling rates to optimize crystallinity, impacting their mechanical properties and end-use applications in packaging, automotive, and consumer goods.

Choosing the Right Material for Your Product

Polyethylene offers excellent chemical resistance and flexibility, making it ideal for packaging films and containers, while polypropylene provides higher heat resistance and rigidity, suitable for automotive parts and reusable containers. Selecting the right plastic depends on product requirements such as durability, temperature tolerance, and exposure to chemicals. Consider mechanical strength, environmental stress, and cost-effectiveness when deciding between polyethylene and polypropylene for your application.

Polyethylene vs Polypropylene Infographic

materialdif.com

materialdif.com