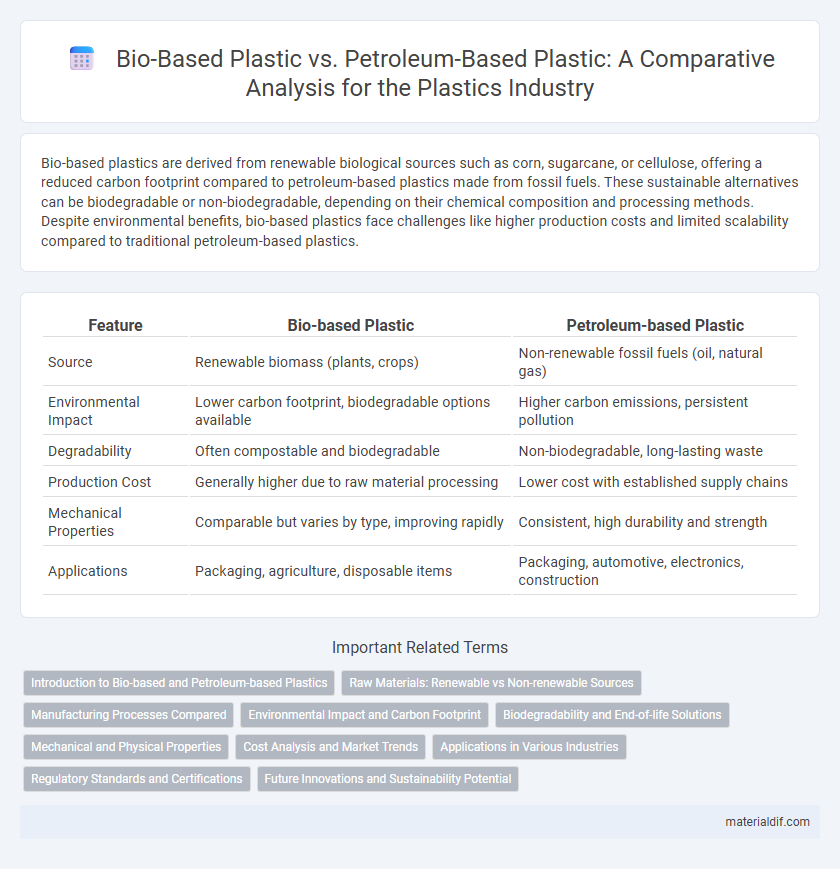

Bio-based plastics are derived from renewable biological sources such as corn, sugarcane, or cellulose, offering a reduced carbon footprint compared to petroleum-based plastics made from fossil fuels. These sustainable alternatives can be biodegradable or non-biodegradable, depending on their chemical composition and processing methods. Despite environmental benefits, bio-based plastics face challenges like higher production costs and limited scalability compared to traditional petroleum-based plastics.

Table of Comparison

| Feature | Bio-based Plastic | Petroleum-based Plastic |

|---|---|---|

| Source | Renewable biomass (plants, crops) | Non-renewable fossil fuels (oil, natural gas) |

| Environmental Impact | Lower carbon footprint, biodegradable options available | Higher carbon emissions, persistent pollution |

| Degradability | Often compostable and biodegradable | Non-biodegradable, long-lasting waste |

| Production Cost | Generally higher due to raw material processing | Lower cost with established supply chains |

| Mechanical Properties | Comparable but varies by type, improving rapidly | Consistent, high durability and strength |

| Applications | Packaging, agriculture, disposable items | Packaging, automotive, electronics, construction |

Introduction to Bio-based and Petroleum-based Plastics

Bio-based plastics are derived from renewable biomass sources such as corn starch, sugarcane, and cellulose, offering a sustainable alternative to conventional plastics. Petroleum-based plastics, synthesized from fossil fuels like crude oil and natural gas, dominate the global plastic market due to their durability and cost-effectiveness. Understanding the differences in raw materials and environmental impacts is crucial for evaluating their roles in reducing plastic pollution and advancing circular economy goals.

Raw Materials: Renewable vs Non-renewable Sources

Bio-based plastics are derived from renewable biomass sources such as corn, sugarcane, and cellulose, which reduce dependence on finite fossil fuels. Petroleum-based plastics originate from non-renewable crude oil and natural gas, contributing to resource depletion and environmental concerns. Utilizing renewable raw materials in bio-based plastics supports sustainability and lowers carbon footprints compared to their petroleum-based counterparts.

Manufacturing Processes Compared

Bio-based plastics are derived from renewable biomass sources such as corn, sugarcane, or cellulose, utilizing fermentation and polymerization techniques to produce biopolymers like polylactic acid (PLA). Petroleum-based plastics rely on petrochemical processes including cracking and polymerization of fossil fuel-derived monomers such as ethylene and propylene, resulting in polymers like polyethylene and polypropylene. Manufacturing bio-based plastics generally requires less energy and emits fewer greenhouse gases compared to the energy-intensive refining and processing of crude oil in petroleum-based plastic production.

Environmental Impact and Carbon Footprint

Bio-based plastics significantly reduce carbon footprints by utilizing renewable resources like corn and sugarcane, which absorb CO2 during growth, whereas petroleum-based plastics release high levels of greenhouse gases during extraction and processing. The environmental impact of bio-based plastics includes lower fossil fuel dependency and improved biodegradability, contributing to decreased landfill accumulation and marine pollution. However, land use changes for bio-based feedstocks can affect biodiversity and water resources, requiring sustainable production practices to maximize ecological benefits.

Biodegradability and End-of-life Solutions

Bio-based plastics, derived from renewable biomass, generally exhibit enhanced biodegradability compared to petroleum-based plastics, which are predominantly resistant to natural degradation processes. End-of-life solutions for bio-based plastics often include composting, anaerobic digestion, and industrial biodegradation, offering sustainable waste management options that reduce environmental impact. Petroleum-based plastics primarily rely on mechanical recycling or landfill disposal, contributing to long-term pollution and accumulation of non-degradable microplastics in ecosystems.

Mechanical and Physical Properties

Bio-based plastics typically exhibit lower tensile strength and thermal resistance compared to petroleum-based plastics, making them less suitable for high-stress industrial applications. Petroleum-based plastics offer superior mechanical durability, impact resistance, and dimensional stability, which contribute to their widespread use in automotive and packaging industries. Advances in bio-based polymer formulations are gradually enhancing the physical properties, yet petroleum-derived plastics currently dominate in performance-critical contexts.

Cost Analysis and Market Trends

Bio-based plastics often exhibit higher initial production costs compared to petroleum-based plastics due to raw material sourcing and processing technologies, yet decreasing feedstock expenses and regulatory incentives are narrowing this gap. Market trends show increasing demand for bio-based plastics driven by consumer preference for sustainability and government policies targeting carbon footprint reduction, resulting in projected compound annual growth rates (CAGR) of over 15% in bio-based plastic segments. In contrast, petroleum-based plastics maintain cost advantages and established infrastructure, though their market share faces gradual decline amid environmental concerns and shifting regulatory frameworks.

Applications in Various Industries

Bio-based plastics are increasingly utilized in packaging, automotive, and agriculture due to their biodegradability and renewable origins, reducing environmental impact compared to petroleum-based plastics. Petroleum-based plastics dominate in construction, electronics, and consumer goods for their cost-effectiveness, durability, and versatility. Industry adoption depends on performance requirements, environmental regulations, and sustainability goals driving the shift towards bio-based alternatives.

Regulatory Standards and Certifications

Bio-based plastics are increasingly subject to rigorous regulatory standards such as ASTM D6866 and EN 16575, which verify their renewable carbon content and biodegradability, ensuring compliance with sustainability goals. Petroleum-based plastics primarily follow regulations like REACH and the U.S. Toxic Substances Control Act (TSCA), focusing on chemical safety and environmental impact. Certifications such as the USDA BioPreferred label for bio-based plastics and the Resin Identification Code (RIC) for petroleum-based plastics guide consumers on material origin and recyclability.

Future Innovations and Sustainability Potential

Future innovations in bio-based plastics emphasize enhancing biodegradability and reducing carbon footprints through advanced biotechnology and green chemistry. Research focuses on developing scalable production methods using renewable feedstocks like agricultural waste, improving material performance comparable to petroleum-based plastics. Sustainable potential lies in circular economy integration, where bio-based plastics enable closed-loop recycling and lower environmental impact compared to conventional fossil-fuel-derived polymers.

Bio-based Plastic vs Petroleum-based Plastic Infographic

materialdif.com

materialdif.com