Polyethylene (PE) offers excellent flexibility and impact resistance, making it ideal for packaging and plastic bags, while Polypropylene (PP) provides higher stiffness and heat resistance, suitable for automotive parts and reusable containers. PE has a simpler chemical structure allowing for greater clarity and softness, whereas PP's crystalline structure enhances durability and chemical resistance. Both are versatile thermoplastics, but the choice depends on application-specific requirements such as temperature tolerance and mechanical strength.

Table of Comparison

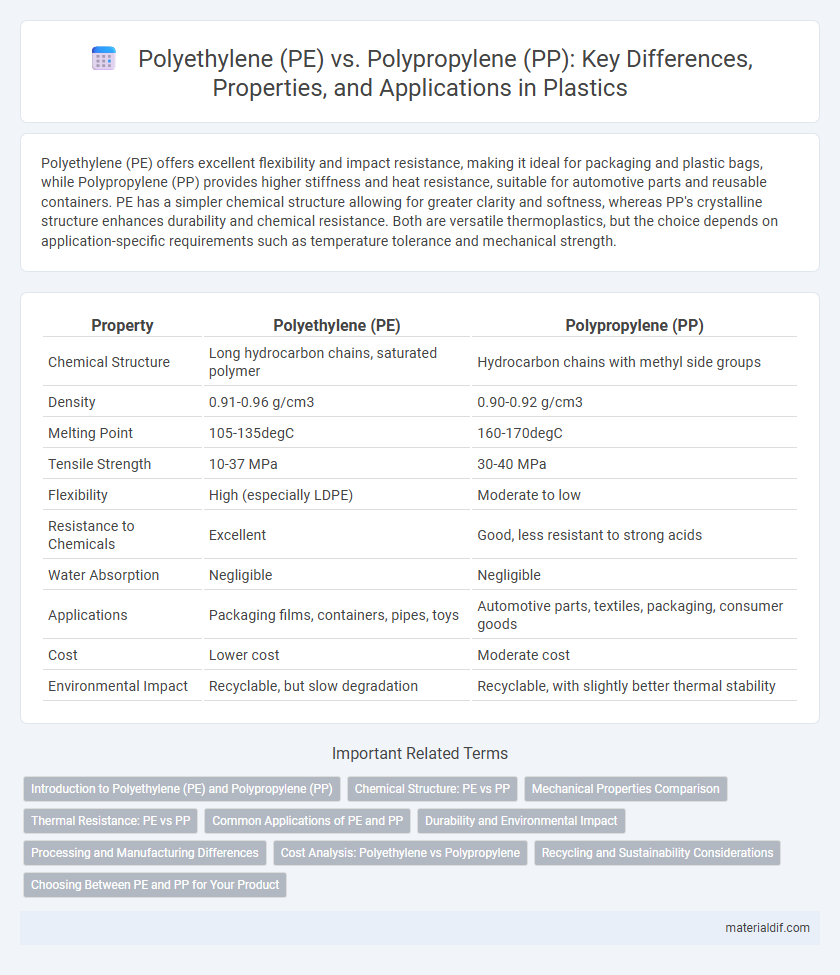

| Property | Polyethylene (PE) | Polypropylene (PP) |

|---|---|---|

| Chemical Structure | Long hydrocarbon chains, saturated polymer | Hydrocarbon chains with methyl side groups |

| Density | 0.91-0.96 g/cm3 | 0.90-0.92 g/cm3 |

| Melting Point | 105-135degC | 160-170degC |

| Tensile Strength | 10-37 MPa | 30-40 MPa |

| Flexibility | High (especially LDPE) | Moderate to low |

| Resistance to Chemicals | Excellent | Good, less resistant to strong acids |

| Water Absorption | Negligible | Negligible |

| Applications | Packaging films, containers, pipes, toys | Automotive parts, textiles, packaging, consumer goods |

| Cost | Lower cost | Moderate cost |

| Environmental Impact | Recyclable, but slow degradation | Recyclable, with slightly better thermal stability |

Introduction to Polyethylene (PE) and Polypropylene (PP)

Polyethylene (PE) and Polypropylene (PP) are two of the most widely used thermoplastic polymers in the plastics industry, known for their versatility and durability. Polyethylene offers excellent chemical resistance and impact strength, making it ideal for packaging, containers, and plastic bags. Polypropylene exhibits a higher melting point and rigidity, suited for automotive parts, textiles, and reusable containers.

Chemical Structure: PE vs PP

Polyethylene (PE) consists of a simple linear or branched chain of repeating ethylene units, characterized by strong C-C and C-H bonds that contribute to its chemical resistance and flexibility. Polypropylene (PP) differs by having a methyl group (-CH3) attached to every other carbon atom in the backbone, creating a more complex, semi-crystalline structure that enhances rigidity and higher melting point. The presence of the methyl side group in PP significantly influences its mechanical properties, making it stiffer and more heat-resistant compared to PE.

Mechanical Properties Comparison

Polyethylene (PE) exhibits higher impact resistance and flexibility, making it ideal for applications requiring toughness and durability. Polypropylene (PP) offers superior tensile strength and stiffness, enhancing its performance in load-bearing and structural uses. Both plastics demonstrate excellent chemical resistance, but PE generally provides better elongation at break, while PP excels in hardness and thermal stability.

Thermal Resistance: PE vs PP

Polypropylene (PP) exhibits superior thermal resistance compared to Polyethylene (PE), with a melting point around 160-170degC versus PE's range of 105-135degC depending on the type (HDPE or LDPE). PP maintains its structural integrity at higher temperatures, making it suitable for applications involving heat exposure, such as microwave containers and automotive parts. Polyethylene tends to soften and deform at lower temperatures, limiting its use in high-heat environments.

Common Applications of PE and PP

Polyethylene (PE) is widely used in packaging films, plastic bags, containers, and bottles due to its flexibility and chemical resistance. Polypropylene (PP) finds common applications in automotive parts, reusable containers, textiles, and medical devices because of its higher melting point and rigidity. Both plastics are essential in manufacturing durable, lightweight products across diverse industries.

Durability and Environmental Impact

Polypropylene (PP) exhibits higher tensile strength and greater fatigue resistance compared to polyethylene (PE), making PP more durable for automotive parts and reusable containers. Polyethylene, especially high-density polyethylene (HDPE), is easier to recycle and has a lower carbon footprint due to simpler polymer chains and catalytic processes. Despite PP's robustness, PE's widespread recyclability and biodegradability potential contribute to a reduced environmental impact in packaging and single-use products.

Processing and Manufacturing Differences

Polyethylene (PE) offers easier processing with lower melting points typically between 105-135degC, facilitating extrusion and molding at lower temperatures, while polypropylene (PP) requires higher processing temperatures around 160-170degC, providing superior heat resistance and rigidity in manufactured products. PE's flexibility and chemical resistance make it ideal for films, bags, and containers, whereas PP's higher tensile strength and fatigue resistance suit automotive parts and reusable packaging. Manufacturing PE involves simpler blow molding and injection molding techniques, while PP demands controlled cooling rates and sometimes nucleating agents to enhance clarity and mechanical properties.

Cost Analysis: Polyethylene vs Polypropylene

Polyethylene (PE) generally offers lower raw material costs compared to Polypropylene (PP), making it a more economical choice for large-volume applications. The production process for PE consumes less energy, further reducing overall manufacturing expenses. However, PP's superior mechanical properties and higher melting point can justify its higher cost in applications requiring greater durability and thermal resistance.

Recycling and Sustainability Considerations

Polyethylene (PE) and Polypropylene (PP) both offer recyclability benefits, but PE has a more established recycling infrastructure due to its widespread use in packaging films and containers. PP's higher melting point allows for better durability but poses challenges in recycling processes, often requiring separation and specialized facilities. Sustainable practices in recycling both polymers include mechanical recycling and chemical recycling methods, with ongoing innovations aimed at reducing environmental impact and improving material recovery rates.

Choosing Between PE and PP for Your Product

Polyethylene (PE) offers excellent chemical resistance and flexibility, making it ideal for applications like packaging films and containers, while Polypropylene (PP) provides higher heat resistance and rigidity, suitable for automotive parts and reusable containers. Consider product requirements such as temperature tolerance, impact resistance, and cost-efficiency when selecting between PE and PP to ensure optimal performance and durability. Material density differences--PE typically ranges from 0.91 to 0.96 g/cm3 and PP around 0.85 to 0.92 g/cm3--also influence weight and strength in final products.

Polyethylene (PE) vs Polypropylene (PP) Infographic

materialdif.com

materialdif.com