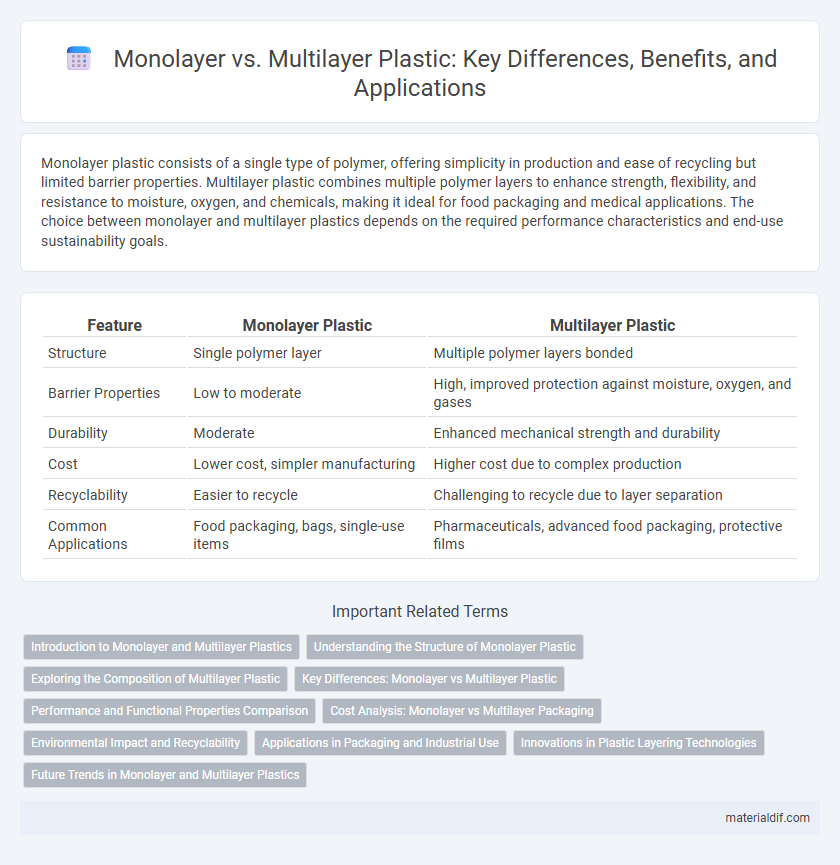

Monolayer plastic consists of a single type of polymer, offering simplicity in production and ease of recycling but limited barrier properties. Multilayer plastic combines multiple polymer layers to enhance strength, flexibility, and resistance to moisture, oxygen, and chemicals, making it ideal for food packaging and medical applications. The choice between monolayer and multilayer plastics depends on the required performance characteristics and end-use sustainability goals.

Table of Comparison

| Feature | Monolayer Plastic | Multilayer Plastic |

|---|---|---|

| Structure | Single polymer layer | Multiple polymer layers bonded |

| Barrier Properties | Low to moderate | High, improved protection against moisture, oxygen, and gases |

| Durability | Moderate | Enhanced mechanical strength and durability |

| Cost | Lower cost, simpler manufacturing | Higher cost due to complex production |

| Recyclability | Easier to recycle | Challenging to recycle due to layer separation |

| Common Applications | Food packaging, bags, single-use items | Pharmaceuticals, advanced food packaging, protective films |

Introduction to Monolayer and Multilayer Plastics

Monolayer plastics consist of a single, uniform polymer layer offering simplicity and ease of recycling but limited barrier properties. Multilayer plastics combine two or more distinct polymer layers, enhancing mechanical strength, gas barriers, and moisture resistance for advanced packaging applications. The choice between monolayer and multilayer plastics depends on performance requirements, cost considerations, and environmental impact.

Understanding the Structure of Monolayer Plastic

Monolayer plastic consists of a single, uniform layer of polymer, designed to provide specific mechanical and barrier properties based on the type of material used. This structure offers simplicity in production and recyclability, but often lacks the enhanced performance characteristics found in multilayer plastics, such as improved moisture or oxygen barrier functions. Understanding the molecular arrangement and thickness of monolayer plastic is crucial for optimizing its strength, flexibility, and application suitability in packaging and industrial uses.

Exploring the Composition of Multilayer Plastic

Multilayer plastic consists of multiple polymer layers, each designed to optimize specific properties such as barrier protection, mechanical strength, and flexibility. Its composition typically includes barrier materials like ethylene vinyl alcohol (EVOH) or polyvinylidene chloride (PVDC) combined with structural polymers such as polyethylene (PE) or polypropylene (PP). This strategic layering enhances performance in packaging by improving resistance to oxygen, moisture, and contaminants, surpassing the limitations of monolayer plastics.

Key Differences: Monolayer vs Multilayer Plastic

Monolayer plastic consists of a single layer of material providing basic barrier properties, while multilayer plastic combines multiple polymer layers engineered to enhance strength, flexibility, and barrier performance against moisture, oxygen, and contaminants. Monolayer films are cost-effective and easier to recycle, but multilayer plastics offer superior protection for sensitive products, extending shelf life significantly. The choice between monolayer and multilayer plastics depends on application requirements such as durability, environmental impact, and product preservation needs.

Performance and Functional Properties Comparison

Monolayer plastics offer simplicity and cost-effectiveness but often lack the enhanced barrier, mechanical strength, and thermal resistance found in multilayer plastics. Multilayer plastics combine diverse polymers to optimize oxygen and moisture barrier properties, improve durability, and provide tailored functionality for specific applications such as food packaging and medical devices. Performance differences significantly impact shelf life, product protection, and environmental resistance, making multilayer plastics preferable for high-demand uses.

Cost Analysis: Monolayer vs Multilayer Packaging

Monolayer plastic packaging generally offers lower production costs due to simpler manufacturing processes and reduced material usage compared to multilayer alternatives. Multilayer packaging, while more expensive, provides enhanced barrier properties and durability, justifying its higher price for applications requiring extended shelf life or protection from moisture and oxygen. A comprehensive cost analysis must balance initial material and production expenses with functional performance benefits to determine the most economical choice for specific packaging needs.

Environmental Impact and Recyclability

Monolayer plastics are generally easier to recycle due to their uniform composition, which facilitates mechanical recycling processes and reduces environmental pollution. Multilayer plastics, composed of different polymer layers, pose significant recycling challenges as separation of materials is complex, often leading to landfill accumulation or incineration. The environmental impact of multilayer plastics is higher, resulting in increased resource consumption and greenhouse gas emissions throughout their lifecycle compared to monolayer alternatives.

Applications in Packaging and Industrial Use

Monolayer plastic films are commonly used in packaging applications requiring simplicity and cost-effectiveness, such as food wrap and grocery bags, due to their uniform structure and ease of recycling. Multilayer plastic films, composed of multiple bonded layers, provide enhanced barrier properties against moisture, oxygen, and contaminants, making them ideal for industrial packaging, pharmaceuticals, and food preservation. The combination of different polymers in multilayer plastics allows customization for specific mechanical strength and chemical resistance, expanding their use in complex packaging solutions.

Innovations in Plastic Layering Technologies

Innovations in plastic layering technologies have transformed the use of monolayer and multilayer plastics by enhancing barrier properties, flexibility, and durability. Advanced co-extrusion and lamination techniques enable the precise combination of different polymers to achieve superior performance in packaging, reducing material consumption and improving recyclability. These developments foster sustainable solutions while meeting industry demands for strength and protection.

Future Trends in Monolayer and Multilayer Plastics

Monolayer plastics offer advantages in recyclability and cost-effectiveness, driving innovation toward bio-based and biodegradable materials to meet sustainability goals. Multilayer plastics are evolving with advanced barrier technologies and selective recyclability to enhance product protection while addressing environmental impact. Future trends emphasize circular economy principles, integrating monolayer and multilayer systems to balance performance with eco-friendly design.

Monolayer vs Multilayer Plastic Infographic

materialdif.com

materialdif.com