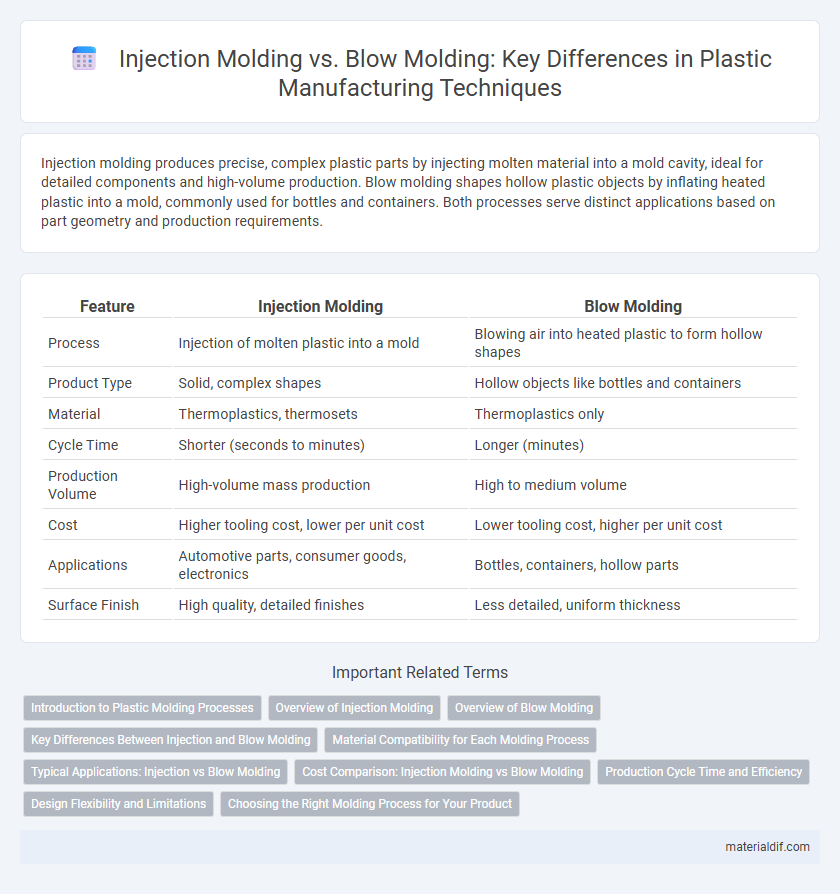

Injection molding produces precise, complex plastic parts by injecting molten material into a mold cavity, ideal for detailed components and high-volume production. Blow molding shapes hollow plastic objects by inflating heated plastic into a mold, commonly used for bottles and containers. Both processes serve distinct applications based on part geometry and production requirements.

Table of Comparison

| Feature | Injection Molding | Blow Molding |

|---|---|---|

| Process | Injection of molten plastic into a mold | Blowing air into heated plastic to form hollow shapes |

| Product Type | Solid, complex shapes | Hollow objects like bottles and containers |

| Material | Thermoplastics, thermosets | Thermoplastics only |

| Cycle Time | Shorter (seconds to minutes) | Longer (minutes) |

| Production Volume | High-volume mass production | High to medium volume |

| Cost | Higher tooling cost, lower per unit cost | Lower tooling cost, higher per unit cost |

| Applications | Automotive parts, consumer goods, electronics | Bottles, containers, hollow parts |

| Surface Finish | High quality, detailed finishes | Less detailed, uniform thickness |

Introduction to Plastic Molding Processes

Injection molding and blow molding are two primary plastic molding processes widely used in manufacturing complex and hollow plastic products. Injection molding involves injecting molten plastic into a mold cavity to create precise, detailed parts with high repeatability, ideal for items like automotive components and consumer electronics. Blow molding uses air pressure to inflate heated plastic into a mold, producing hollow objects such as bottles and containers, making it essential for packaging industries.

Overview of Injection Molding

Injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity, where it cools and solidifies into the desired shape. This method excels in producing highly detailed, complex parts with tight tolerances and is ideal for high-volume production runs. Common applications include automotive components, consumer electronics housings, and medical devices due to its efficiency and precision.

Overview of Blow Molding

Blow molding is a manufacturing process used to create hollow plastic parts by inflating heated plastic inside a mold cavity, commonly employed for producing bottles, containers, and other hollow shapes. This technique offers high efficiency in mass production and allows for complex geometries with uniform wall thickness. Key materials used in blow molding include polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET), which provide durability and flexibility in packaging applications.

Key Differences Between Injection and Blow Molding

Injection molding produces solid, intricate plastic parts by injecting molten material into a mold cavity, making it ideal for complex geometries and high precision applications. Blow molding forms hollow plastic objects by inflating a heated plastic tube inside a mold, primarily used for manufacturing containers like bottles and hollow parts. Key differences include the type of products produced--solid versus hollow--production speed, and material usage efficiency.

Material Compatibility for Each Molding Process

Injection molding is compatible with a wide range of thermoplastics such as ABS, polycarbonate, and nylon, offering high precision for complex geometries. Blow molding primarily works with polyethylene, polypropylene, and PVC, optimizing the production of hollow, lightweight containers. Material selection is crucial to match the thermal and flow properties required by each molding process, ensuring product integrity and efficiency.

Typical Applications: Injection vs Blow Molding

Injection molding is commonly used for manufacturing complex, precise plastic parts such as automotive components, medical devices, and consumer electronics housings. Blow molding is ideal for producing hollow plastic products like bottles, containers, and fuel tanks due to its ability to create lightweight, durable, and seamless shapes. Typical applications highlight injection molding's strength in detailed, high-tolerance items, whereas blow molding excels in packaging and storage solutions requiring uniform wall thickness.

Cost Comparison: Injection Molding vs Blow Molding

Injection molding generally incurs higher initial tooling costs due to complex molds, while blow molding offers lower upfront mold expenses, making it more cost-effective for high-volume production of hollow parts. Per-unit production costs in injection molding decrease with volume but remain higher compared to blow molding for large-scale manufacturing of bottles and containers. Material waste is minimal in injection molding, enhancing cost efficiency, whereas blow molding requires less material per product, further reducing overall costs.

Production Cycle Time and Efficiency

Injection molding offers shorter production cycle times, typically ranging from 15 to 60 seconds per part, enabling high efficiency for complex, high-volume plastic components. Blow molding cycles vary between 20 to 120 seconds depending on the product size and design, optimized for hollow objects like bottles with excellent scalability but generally longer cycles than injection molding. Efficiency in injection molding is driven by rapid cooling and precise material injection, while blow molding maximizes throughput for lightweight, hollow parts with minimal material waste.

Design Flexibility and Limitations

Injection molding offers superior design flexibility with the ability to create complex, detailed shapes and intricate features using multi-cavity molds, supporting tight tolerances and fine surface finishes. Blow molding primarily suits hollow, lightweight structures like bottles and containers but faces limitations in achieving intricate designs or thick walls. Understanding these distinctions guides optimal plastic part selection based on complexity, wall thickness, and functional requirements.

Choosing the Right Molding Process for Your Product

Injection molding excels in producing complex, high-precision plastic parts with intricate details and tight tolerances, ideal for components like automotive parts, electronics housings, and medical devices. Blow molding is preferred for creating hollow, lightweight objects such as bottles, containers, and fuel tanks, offering efficient material usage and faster production cycles. Selecting the right molding process depends on product design, volume requirements, wall thickness, and intended functionality to optimize cost-efficiency and quality.

Injection Molding vs Blow Molding Infographic

materialdif.com

materialdif.com