OPA barrier film offers excellent mechanical strength and moisture resistance, making it ideal for packaging applications requiring durability and protection against water vapor. EVOH barrier film provides superior oxygen barrier properties, effectively preserving product freshness and extending shelf life for sensitive goods. Choosing between OPA and EVOH films depends on whether moisture protection or oxygen barrier performance is the primary packaging requirement.

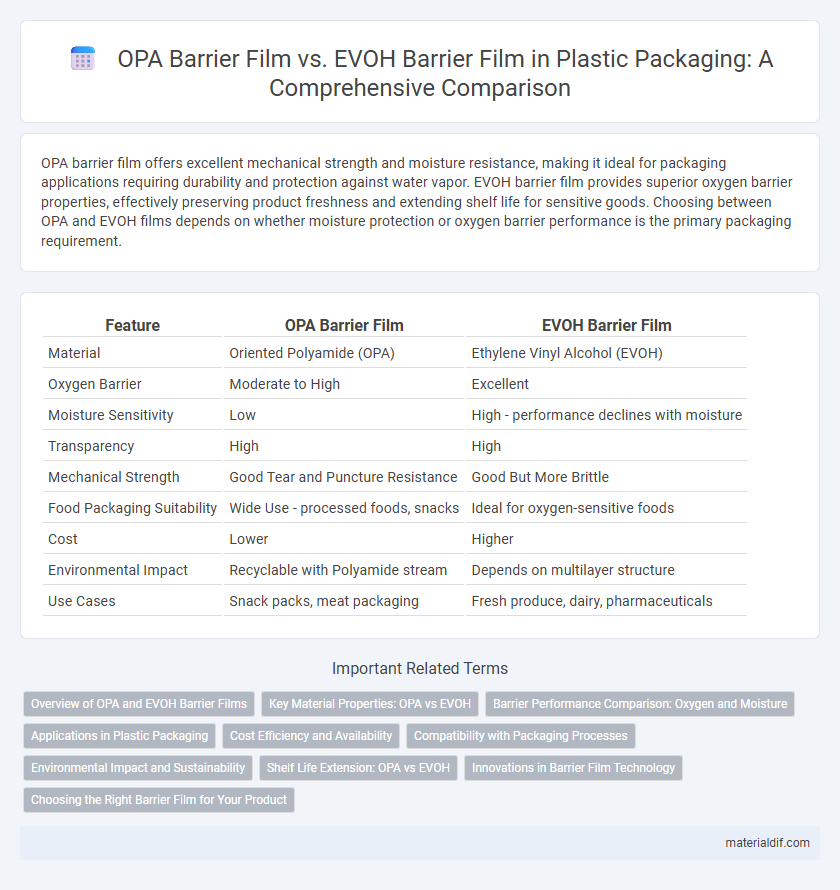

Table of Comparison

| Feature | OPA Barrier Film | EVOH Barrier Film |

|---|---|---|

| Material | Oriented Polyamide (OPA) | Ethylene Vinyl Alcohol (EVOH) |

| Oxygen Barrier | Moderate to High | Excellent |

| Moisture Sensitivity | Low | High - performance declines with moisture |

| Transparency | High | High |

| Mechanical Strength | Good Tear and Puncture Resistance | Good But More Brittle |

| Food Packaging Suitability | Wide Use - processed foods, snacks | Ideal for oxygen-sensitive foods |

| Cost | Lower | Higher |

| Environmental Impact | Recyclable with Polyamide stream | Depends on multilayer structure |

| Use Cases | Snack packs, meat packaging | Fresh produce, dairy, pharmaceuticals |

Overview of OPA and EVOH Barrier Films

OPA (Oriented Polyamide) barrier film offers excellent mechanical strength, flexibility, and high oxygen barrier properties, making it ideal for food packaging that requires durability and longer shelf life. EVOH (Ethylene Vinyl Alcohol) barrier film is known for its superior oxygen and gas barrier performance, even at low humidity levels, which helps preserve product freshness and extend shelf life significantly. Both films are widely used in multilayer packaging applications, but EVOH is preferred when maximum gas impermeability is critical, while OPA is favored for its toughness and heat resistance.

Key Material Properties: OPA vs EVOH

OPA (Oriented Polyamide) film exhibits excellent mechanical strength, high puncture resistance, and superior flexibility, making it ideal for demanding packaging applications. EVOH (Ethylene Vinyl Alcohol) film provides exceptional gas barrier properties, particularly against oxygen, ensuring prolonged product shelf life and freshness. While OPA offers robust physical durability, EVOH excels in moisture and aroma retention, often paired together for enhanced multi-layer packaging performance.

Barrier Performance Comparison: Oxygen and Moisture

OPA barrier film exhibits superior oxygen barrier properties with oxygen transmission rates (OTR) as low as 0.1 cc/m2/day, making it ideal for sensitive food packaging. EVOH barrier film provides excellent oxygen barrier performance but is highly sensitive to moisture, causing its OTR to increase significantly in high humidity environments. Moisture barrier performance favors OPA films due to their inherent hydrophobic nature, delivering better protection against water vapor transmission rates (WVTR) compared to EVOH films.

Applications in Plastic Packaging

OPA barrier film exhibits excellent oxygen and aroma barrier properties, making it ideal for packaging sensitive food products such as snacks, coffee, and ready-to-eat meals. EVOH barrier film offers superior gas barrier performance, especially against oxygen, and is widely used in multilayer packaging for fresh meat, dairy products, and pharmaceuticals to extend shelf life. Both films enhance product protection, but EVOH's high clarity and chemical resistance often favor applications requiring transparency and stringent barrier requirements.

Cost Efficiency and Availability

OPA barrier films typically offer higher cost efficiency compared to EVOH films due to lower raw material and production costs, making them a preferred choice for budget-sensitive packaging applications. EVOH barrier films provide superior oxygen barrier properties but come with higher expenses and limited availability in certain regions due to complex manufacturing processes and supply chain constraints. When balancing cost efficiency and availability, OPA films often dominate in markets requiring large volume packaging solutions under tight budget constraints.

Compatibility with Packaging Processes

OPA barrier film offers excellent compatibility with various packaging processes such as heat sealing, vacuum packaging, and MAP (Modified Atmosphere Packaging) due to its high thermal stability and mechanical strength. EVOH barrier film excels in gas barrier properties but requires careful handling during extrusion and lamination to maintain its integrity within multilayer packaging structures. Both materials integrate well with standard packaging lines, but EVOH may need specific adhesives or tie layers to enhance adhesion and process compatibility in complex packaging applications.

Environmental Impact and Sustainability

OPA barrier film offers high gas barrier properties with better recyclability due to its simpler polymer structure, reducing environmental footprint during recycling processes. EVOH barrier film provides excellent oxygen and moisture resistance but poses challenges in recycling because of its multilayer composition, leading to increased energy consumption and waste. Choosing OPA films can enhance sustainability efforts by facilitating circular economy practices and lowering overall plastic pollution.

Shelf Life Extension: OPA vs EVOH

OPA (Oriented Polyamide) barrier films provide excellent oxygen and moisture resistance, significantly extending the shelf life of packaged products by maintaining product freshness and preventing spoilage. EVOH (Ethylene Vinyl Alcohol) films offer superior gas barrier properties, particularly against oxygen, enabling longer shelf life for sensitive foods like meats and dairy. Comparing shelf life extension, EVOH typically outperforms OPA due to its higher oxygen barrier efficiency, although OPA's moisture resistance benefits certain high-humidity environments.

Innovations in Barrier Film Technology

OPA barrier films offer enhanced mechanical strength and excellent moisture resistance, making them ideal for food packaging applications requiring durability. EVOH barrier films provide superior oxygen barrier properties, significantly extending shelf life by preventing oxidation and preserving product freshness. Innovations in barrier film technology focus on multilayer co-extrusion and nanocomposite enhancements, combining OPA's toughness with EVOH's oxygen impermeability to create advanced films with optimal performance and sustainability.

Choosing the Right Barrier Film for Your Product

Choosing the right barrier film depends on the specific requirements of your product, such as moisture and oxygen resistance. OPA (Oriented Polyamide) barrier films offer excellent mechanical strength and high oxygen barrier properties, making them ideal for packaging sensitive food items. EVOH (Ethylene Vinyl Alcohol) provides superior oxygen barrier performance especially under low humidity conditions, but requires lamination with moisture-resistant films for optimal protection.

OPA Barrier Film vs EVOH Barrier Film Infographic

materialdif.com

materialdif.com