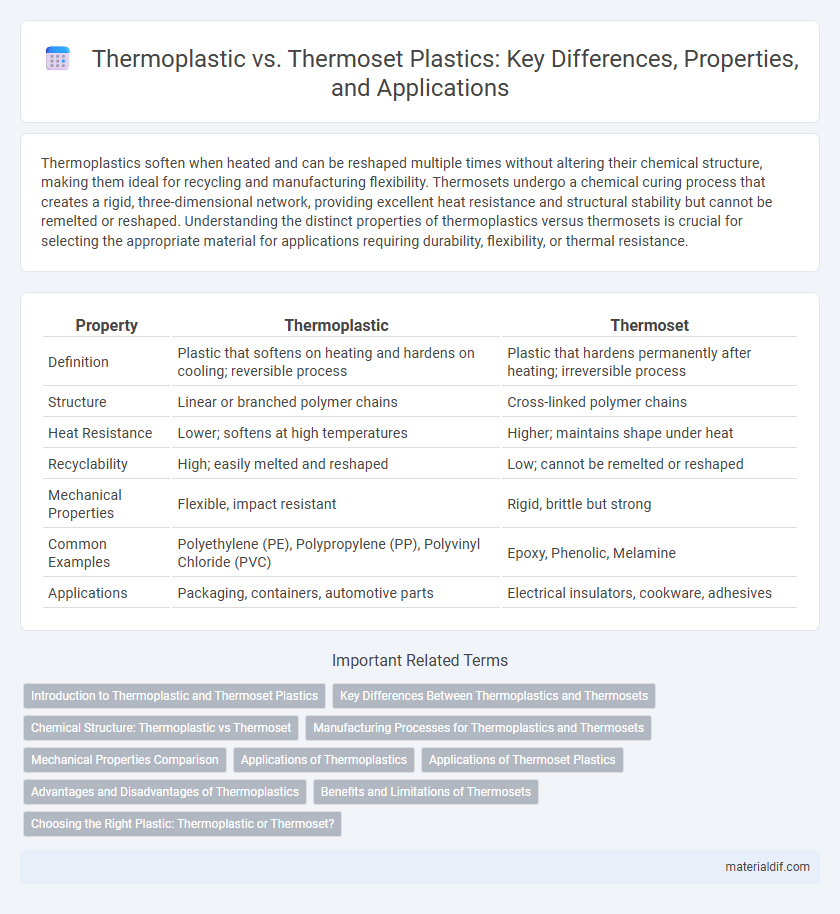

Thermoplastics soften when heated and can be reshaped multiple times without altering their chemical structure, making them ideal for recycling and manufacturing flexibility. Thermosets undergo a chemical curing process that creates a rigid, three-dimensional network, providing excellent heat resistance and structural stability but cannot be remelted or reshaped. Understanding the distinct properties of thermoplastics versus thermosets is crucial for selecting the appropriate material for applications requiring durability, flexibility, or thermal resistance.

Table of Comparison

| Property | Thermoplastic | Thermoset |

|---|---|---|

| Definition | Plastic that softens on heating and hardens on cooling; reversible process | Plastic that hardens permanently after heating; irreversible process |

| Structure | Linear or branched polymer chains | Cross-linked polymer chains |

| Heat Resistance | Lower; softens at high temperatures | Higher; maintains shape under heat |

| Recyclability | High; easily melted and reshaped | Low; cannot be remelted or reshaped |

| Mechanical Properties | Flexible, impact resistant | Rigid, brittle but strong |

| Common Examples | Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC) | Epoxy, Phenolic, Melamine |

| Applications | Packaging, containers, automotive parts | Electrical insulators, cookware, adhesives |

Introduction to Thermoplastic and Thermoset Plastics

Thermoplastic plastics consist of polymer chains that soften when heated and harden upon cooling, allowing for repeated reshaping without altering their chemical structure. Thermoset plastics, in contrast, undergo a curing process that creates irreversible cross-linked bonds, resulting in a rigid and heat-resistant material that cannot be remelted. These fundamental differences in molecular structure impact their applications, machinability, and recyclability in industries like automotive, electronics, and packaging.

Key Differences Between Thermoplastics and Thermosets

Thermoplastics can be repeatedly melted and reshaped due to their linear polymer chains, whereas thermosets undergo a chemical curing process that creates a rigid, three-dimensional network, preventing reshaping. Thermoplastics are generally more flexible and recyclable, making them suitable for applications like packaging and automotive parts, while thermosets offer superior heat resistance and structural integrity, ideal for electrical insulators and adhesives. Understanding these differences is crucial for selecting materials based on durability, thermal stability, and recyclability requirements in manufacturing.

Chemical Structure: Thermoplastic vs Thermoset

Thermoplastics consist of linear or branched polymer chains without cross-linking, allowing them to soften and melt upon heating. Thermosets feature heavily cross-linked, three-dimensional polymer networks that create a rigid structure resistant to melting after curing. This fundamental difference in chemical structure dictates their thermal behavior, recyclability, and mechanical properties.

Manufacturing Processes for Thermoplastics and Thermosets

Thermoplastics undergo manufacturing processes such as injection molding, extrusion, and blow molding, where they are heated to a pliable state and reshaped repeatedly without altering their chemical structure. Thermosets, however, are formed through irreversible curing processes like compression molding and transfer molding, where heat or catalysts induce cross-linking, resulting in a rigid, durable material that cannot be re-melted. These distinct manufacturing methods reflect their fundamental polymer structures, with thermoplastics offering recyclability and versatility, while thermosets provide superior mechanical strength and thermal stability.

Mechanical Properties Comparison

Thermoplastics exhibit greater flexibility and impact resistance due to their linear molecular structure, allowing for easier reshaping and recycling. Thermosets possess superior thermal stability and higher tensile strength, resulting from their cross-linked polymer network that enhances rigidity and chemical resistance. Mechanical properties such as elongation at break and hardness favor thermoplastics for applications requiring toughness, while thermosets excel in structural components demanding dimensional stability and heat endurance.

Applications of Thermoplastics

Thermoplastics are widely used in automotive components, packaging materials, and consumer electronics due to their ability to be repeatedly molded and recycled. Their flexibility, impact resistance, and lightweight properties make them ideal for manufacturing items like plastic bottles, containers, and medical devices. Common thermoplastics such as polyethylene, polypropylene, and polycarbonate enable cost-effective production and versatile applications across various industries.

Applications of Thermoset Plastics

Thermoset plastics are extensively used in electrical insulation, automotive components, and aerospace applications due to their superior heat resistance and mechanical strength. Their cross-linked molecular structure ensures durability and stability under high temperatures, making them ideal for circuit boards, engine parts, and composite materials. Common thermoset polymers include epoxy, phenolic, and polyester resins, which provide excellent chemical resistance and structural integrity in demanding environments.

Advantages and Disadvantages of Thermoplastics

Thermoplastics offer advantages such as recyclability, ease of molding, and the ability to be reshaped multiple times, making them ideal for mass production and diverse applications. They typically have lower resistance to heat and chemicals compared to thermosets, which limits their use in high-temperature or harsh environments. The primary disadvantage of thermoplastics is their lower mechanical strength and susceptibility to deformation under stress, unlike thermosets that provide superior durability and structural stability.

Benefits and Limitations of Thermosets

Thermoset plastics offer exceptional thermal resistance and structural integrity, making them ideal for high-temperature applications and durable products like electrical insulators and automotive parts. Their cross-linked molecular structure prevents reshaping after curing, which limits recyclability and repair options compared to thermoplastics. Despite these limitations, thermosets provide superior chemical resistance and mechanical strength, enhancing performance in demanding environments.

Choosing the Right Plastic: Thermoplastic or Thermoset?

Thermoplastics offer flexibility and recyclability due to their ability to melt and remold multiple times, making them ideal for applications requiring reshaping or repair. Thermosets provide superior chemical resistance and structural integrity by forming irreversible bonds during curing, suited for high-temperature or high-stress environments. Selecting between thermoplastic and thermoset depends on factors like mechanical strength requirements, temperature exposure, and recyclability needs, guiding optimal material performance and lifecycle.

Thermoplastic vs Thermoset Infographic

materialdif.com

materialdif.com