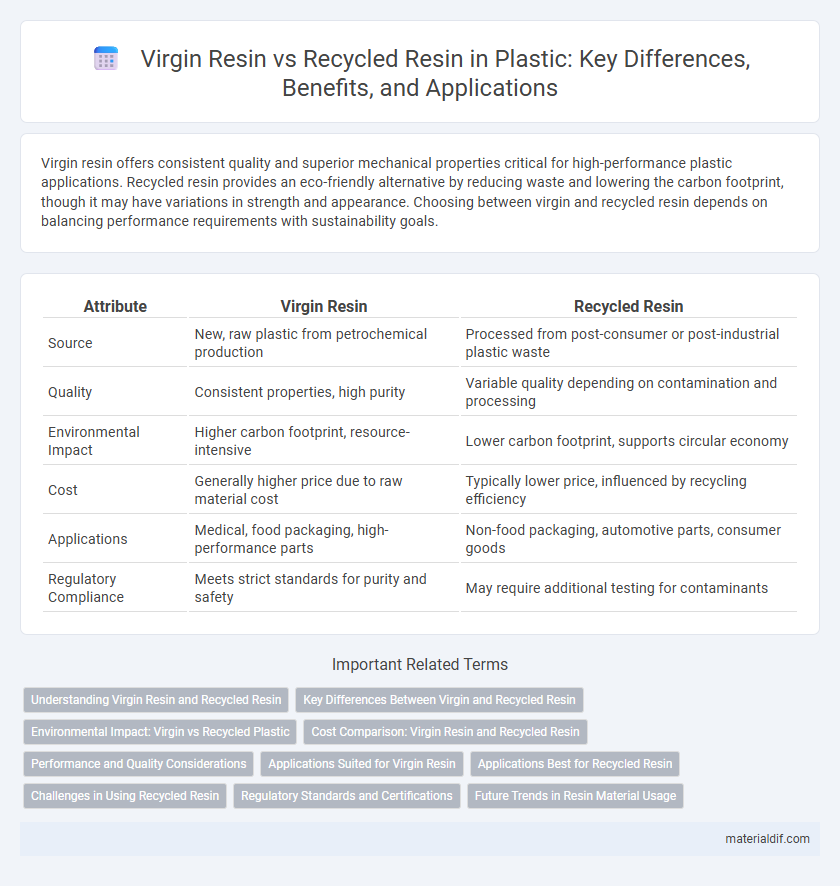

Virgin resin offers consistent quality and superior mechanical properties critical for high-performance plastic applications. Recycled resin provides an eco-friendly alternative by reducing waste and lowering the carbon footprint, though it may have variations in strength and appearance. Choosing between virgin and recycled resin depends on balancing performance requirements with sustainability goals.

Table of Comparison

| Attribute | Virgin Resin | Recycled Resin |

|---|---|---|

| Source | New, raw plastic from petrochemical production | Processed from post-consumer or post-industrial plastic waste |

| Quality | Consistent properties, high purity | Variable quality depending on contamination and processing |

| Environmental Impact | Higher carbon footprint, resource-intensive | Lower carbon footprint, supports circular economy |

| Cost | Generally higher price due to raw material cost | Typically lower price, influenced by recycling efficiency |

| Applications | Medical, food packaging, high-performance parts | Non-food packaging, automotive parts, consumer goods |

| Regulatory Compliance | Meets strict standards for purity and safety | May require additional testing for contaminants |

Understanding Virgin Resin and Recycled Resin

Virgin resin is a raw plastic material produced directly from petrochemicals, offering consistent quality, superior mechanical properties, and high purity, making it ideal for applications demanding stringent performance standards. Recycled resin, derived from processed post-consumer or post-industrial plastic waste, varies in quality due to contamination and degradation but significantly reduces environmental impact by conserving resources and decreasing landfill waste. Understanding the differences between virgin and recycled resin is crucial for manufacturers aiming to balance performance requirements with sustainability goals in their plastic production processes.

Key Differences Between Virgin and Recycled Resin

Virgin resin is produced from raw petrochemicals, offering consistent quality, higher purity, and superior mechanical properties compared to recycled resin. Recycled resin, derived from post-consumer or post-industrial plastic waste, often contains impurities and shows variability in color, strength, and thermal stability. The choice between virgin and recycled resin impacts product performance, cost, and environmental sustainability in plastic manufacturing.

Environmental Impact: Virgin vs Recycled Plastic

Virgin resin production consumes significantly more energy and natural resources compared to recycled resin, leading to higher greenhouse gas emissions and environmental degradation. Recycled resin reduces landfill waste and lowers carbon footprint by reusing existing plastic materials, conserving fossil fuels, and decreasing pollution. Choosing recycled plastic supports circular economy principles by minimizing resource extraction and promoting sustainable manufacturing practices.

Cost Comparison: Virgin Resin and Recycled Resin

Virgin resin generally incurs higher production costs due to raw material extraction and energy-intensive processes, resulting in a higher price point compared to recycled resin. Recycled resin offers cost advantages by repurposing post-consumer or post-industrial plastic waste, reducing material expenses and lowering overall manufacturing costs. Price fluctuations in virgin resin are influenced by crude oil markets, while recycled resin prices depend on collection, sorting efficiency, and market demand for recycled plastics.

Performance and Quality Considerations

Virgin resin offers superior mechanical strength, clarity, and consistency compared to recycled resin, which may contain contaminants or degraded polymers affecting performance. Recycled resin tends to have variable melt flow rates and potential odor issues due to residual impurities, limiting its application in high-precision or food-grade products. Selecting virgin resin ensures optimal durability and surface finish, crucial for critical applications demanding stringent quality standards.

Applications Suited for Virgin Resin

Virgin resin exhibits superior mechanical strength and chemical resistance, making it ideal for high-performance applications such as medical devices, food packaging, and automotive parts. Its consistent purity and color stability ensure optimal performance in precision molding and electronic components. Industries demanding stringent regulatory compliance and durability predominantly prefer virgin resin for reliable and safe product manufacturing.

Applications Best for Recycled Resin

Recycled resin is ideal for non-food packaging, automotive components, and construction materials where high strength and flexibility are essential. Its sustainable nature lowers environmental impact, making it suitable for manufacturing household items, gardening tools, and consumer electronics casings. Despite slightly lower purity, recycled resin meets industry standards for durability and cost-efficiency in applications not requiring pristine virgin resin characteristics.

Challenges in Using Recycled Resin

Recycled resin faces challenges such as inconsistent quality and contamination, which can affect the mechanical properties and appearance of the final plastic products. Variability in polymer composition and the presence of residual additives or impurities hinder its performance in high-precision applications. These issues necessitate advanced sorting, cleaning technologies, and quality control measures to ensure recycled resins meet industry standards.

Regulatory Standards and Certifications

Virgin resin complies with stringent regulatory standards such as FDA, EU food contact regulations, and REACH, ensuring purity and safety for sensitive applications. Recycled resin certifications like ISCC Plus and OEKO-TEX certify traceability and compliance with environmental standards but may face variability in contaminant thresholds. Both resins must meet specific sectoral requirements, with recycled resin's evolving certifications increasingly aligning with global sustainability directives.

Future Trends in Resin Material Usage

Future trends in resin material usage indicate a growing preference for recycled resin due to increasing environmental regulations and corporate sustainability goals. Innovations in recycling technologies are enhancing the quality and performance of recycled resin, making it a viable alternative to virgin resin in many applications. Market demand is shifting towards circular economy models, where recycled resin plays a critical role in reducing plastic waste and conserving natural resources.

Virgin Resin vs Recycled Resin Infographic

materialdif.com

materialdif.com