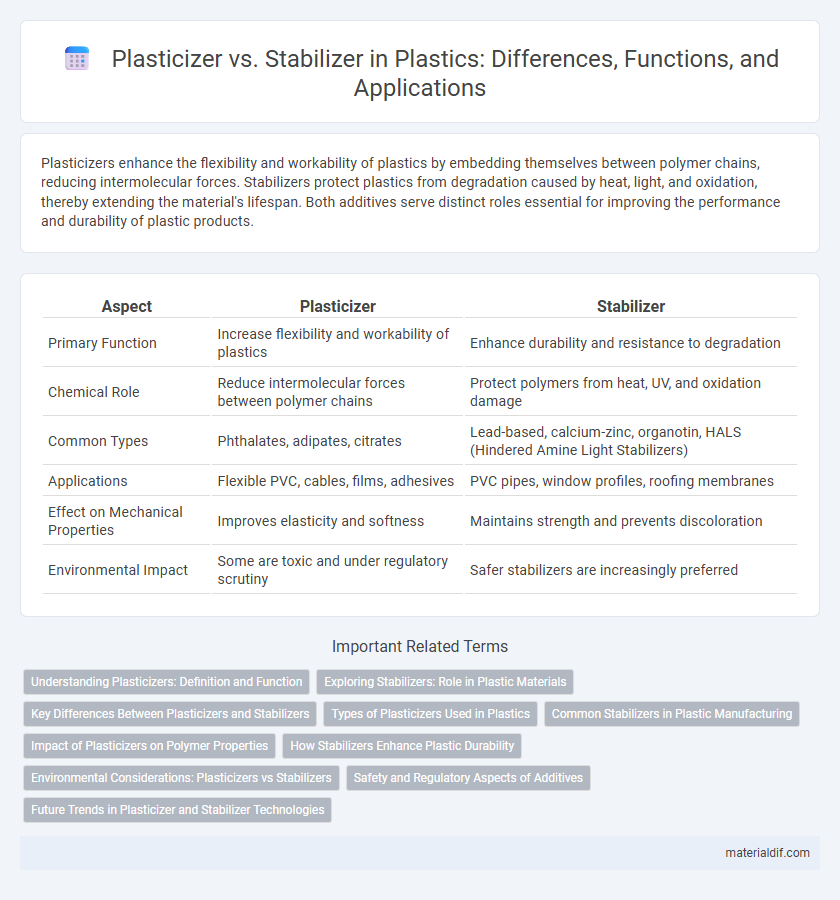

Plasticizers enhance the flexibility and workability of plastics by embedding themselves between polymer chains, reducing intermolecular forces. Stabilizers protect plastics from degradation caused by heat, light, and oxidation, thereby extending the material's lifespan. Both additives serve distinct roles essential for improving the performance and durability of plastic products.

Table of Comparison

| Aspect | Plasticizer | Stabilizer |

|---|---|---|

| Primary Function | Increase flexibility and workability of plastics | Enhance durability and resistance to degradation |

| Chemical Role | Reduce intermolecular forces between polymer chains | Protect polymers from heat, UV, and oxidation damage |

| Common Types | Phthalates, adipates, citrates | Lead-based, calcium-zinc, organotin, HALS (Hindered Amine Light Stabilizers) |

| Applications | Flexible PVC, cables, films, adhesives | PVC pipes, window profiles, roofing membranes |

| Effect on Mechanical Properties | Improves elasticity and softness | Maintains strength and prevents discoloration |

| Environmental Impact | Some are toxic and under regulatory scrutiny | Safer stabilizers are increasingly preferred |

Understanding Plasticizers: Definition and Function

Plasticizers are additives that increase the flexibility, workability, and durability of plastics by reducing intermolecular forces between polymer chains. Unlike stabilizers, which protect plastics from degradation caused by heat, light, and oxidation, plasticizers primarily enhance the material's softness and extensibility. Common plasticizers include phthalates and adipates, widely used to improve the performance of PVC and other polymers.

Exploring Stabilizers: Role in Plastic Materials

Stabilizers in plastic materials enhance durability by preventing degradation caused by heat, light, and oxygen exposure, thereby extending the lifespan of polymers. Unlike plasticizers, which increase flexibility by reducing intermolecular forces, stabilizers maintain the structural integrity and mechanical properties of plastics during processing and end-use. Common stabilizers include heat stabilizers, UV stabilizers, and antioxidants, each tailored to protect specific plastic types such as PVC, polyethylene, and polypropylene.

Key Differences Between Plasticizers and Stabilizers

Plasticizers and stabilizers serve distinct roles in plastic formulation; plasticizers increase flexibility and reduce brittleness by embedding themselves between polymer chains, whereas stabilizers enhance durability by protecting plastics from degradation caused by heat, UV radiation, or oxidation. Plasticizers primarily influence the mechanical properties of plastics like PVC, improving softness and workability, while stabilizers maintain the chemical integrity and longevity of plastic products during processing and use. The concentration and chemical composition of plasticizers and stabilizers are critical factors that determine the performance, safety, and environmental impact of the final plastic material.

Types of Plasticizers Used in Plastics

Plasticizers primarily include phthalates, adipates, and citrates, each enhancing polymer flexibility by reducing intermolecular forces within plastics. Phthalate plasticizers such as di(2-ethylhexyl) phthalate (DEHP) remain the most widely used due to their effectiveness and cost-efficiency. In contrast, stabilizers like lead, calcium-zinc, and organotin compounds serve to increase thermal and UV resistance but do not significantly alter the plastic's flexibility.

Common Stabilizers in Plastic Manufacturing

Common stabilizers in plastic manufacturing include heat stabilizers such as calcium-zinc and lead-based compounds, which prevent degradation during processing by protecting polymer chains from heat and UV exposure. These stabilizers enhance the durability and lifespan of plastics by maintaining their mechanical and aesthetic properties. Unlike plasticizers that increase flexibility by softening polymers, stabilizers primarily focus on preserving the integrity and performance of the plastic material.

Impact of Plasticizers on Polymer Properties

Plasticizers significantly enhance polymer flexibility and elongation by reducing intermolecular forces and increasing chain mobility, which improves material softness and processability. Unlike stabilizers that protect polymers from thermal, UV, or oxidative degradation, plasticizers primarily affect mechanical properties without directly influencing polymer stability. High concentrations of plasticizers can lead to decreased tensile strength and dimensional stability, highlighting the need for balanced formulation in applications such as PVC manufacturing.

How Stabilizers Enhance Plastic Durability

Stabilizers enhance plastic durability by preventing degradation caused by heat, light, and oxygen exposure, thus maintaining the material's physical and chemical properties over time. Unlike plasticizers, which increase flexibility by softening polymers, stabilizers work by inhibiting oxidative and thermal breakdown to extend the lifespan of plastics in harsh environments. Common stabilizers include UV absorbers and antioxidants, which are critical for applications requiring long-term durability and resistance to environmental stressors.

Environmental Considerations: Plasticizers vs Stabilizers

Plasticizers and stabilizers serve distinct functions in plastic production, with significant environmental implications. Plasticizers, primarily phthalates, can leach into ecosystems, posing risks to wildlife and human health due to their endocrine-disrupting properties, while stabilizers such as lead or cadmium-based compounds may introduce heavy metal toxicity concerns during disposal or recycling. The development of bio-based and non-toxic alternatives for both additives is crucial to minimizing plastic pollution and enhancing environmental sustainability.

Safety and Regulatory Aspects of Additives

Plasticizers and stabilizers play distinct roles in polymer formulations, with plasticizers enhancing flexibility and stabilizers improving thermal and UV resistance. Regulatory agencies, including the U.S. EPA and the European Chemicals Agency (ECHA), enforce strict safety guidelines to limit exposure to certain plasticizers such as phthalates, due to their potential endocrine-disrupting effects. Stabilizers, often containing heavy metals like lead or cadmium, face stringent restrictions and are increasingly replaced by safer alternatives to comply with global environmental and health standards.

Future Trends in Plasticizer and Stabilizer Technologies

Future trends in plasticizer and stabilizer technologies emphasize the development of bio-based and non-toxic additives to enhance environmental sustainability and human health safety. Innovations focus on improving compatibility with diverse polymer matrices and increasing resistance to thermal and UV degradation for longer-lasting materials. Advanced nanotechnology and smart additives are emerging to provide tailored performance characteristics, such as self-healing and enhanced mechanical properties in plastic composites.

Plasticizer vs Stabilizer Infographic

materialdif.com

materialdif.com