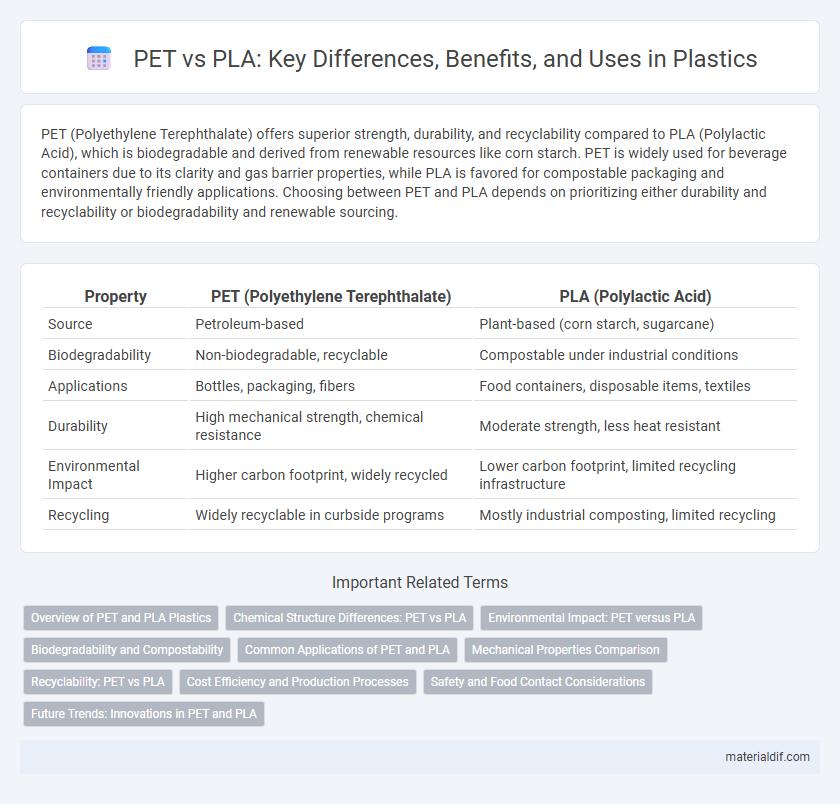

PET (Polyethylene Terephthalate) offers superior strength, durability, and recyclability compared to PLA (Polylactic Acid), which is biodegradable and derived from renewable resources like corn starch. PET is widely used for beverage containers due to its clarity and gas barrier properties, while PLA is favored for compostable packaging and environmentally friendly applications. Choosing between PET and PLA depends on prioritizing either durability and recyclability or biodegradability and renewable sourcing.

Table of Comparison

| Property | PET (Polyethylene Terephthalate) | PLA (Polylactic Acid) |

|---|---|---|

| Source | Petroleum-based | Plant-based (corn starch, sugarcane) |

| Biodegradability | Non-biodegradable, recyclable | Compostable under industrial conditions |

| Applications | Bottles, packaging, fibers | Food containers, disposable items, textiles |

| Durability | High mechanical strength, chemical resistance | Moderate strength, less heat resistant |

| Environmental Impact | Higher carbon footprint, widely recycled | Lower carbon footprint, limited recycling infrastructure |

| Recycling | Widely recyclable in curbside programs | Mostly industrial composting, limited recycling |

Overview of PET and PLA Plastics

PET (polyethylene terephthalate) is a widely used thermoplastic polyester known for its strong, lightweight, and recyclable properties, commonly found in beverage bottles and food containers. PLA (polylactic acid) is a biodegradable, bio-based plastic derived from renewable resources such as corn starch or sugarcane, favored for its compostability and reduced environmental impact. PET offers superior durability and chemical resistance, while PLA excels in sustainability and is primarily used in packaging and disposable products.

Chemical Structure Differences: PET vs PLA

Polyethylene terephthalate (PET) features a repeating ester linkage formed between terephthalic acid and ethylene glycol, resulting in an aromatic polyester with strong chemical stability and high crystallinity. Polylactic acid (PLA) is a biodegradable aliphatic polyester synthesized from lactic acid, characterized by its chiral center and the presence of hydroxyl and carboxyl groups leading to lower crystallinity and enhanced biodegradability. The chemical structure differences between PET and PLA significantly influence their thermal properties, mechanical strength, and environmental impact.

Environmental Impact: PET versus PLA

PET (polyethylene terephthalate) is widely used in packaging due to its durability and recyclability, but its production relies heavily on fossil fuels and can contribute to greenhouse gas emissions. PLA (polylactic acid) is derived from renewable resources like corn starch, offering a compostable alternative with a lower carbon footprint under industrial composting conditions. However, the environmental benefits of PLA are offset by its limited biodegradability in natural environments and challenges in recycling infrastructure.

Biodegradability and Compostability

PET (Polyethylene Terephthalate) is a widely used plastic known for its durability but is not biodegradable and takes centuries to break down in landfills. PLA (Polylactic Acid), derived from renewable resources like corn starch, is both biodegradable and compostable under industrial composting conditions, breaking down within months. The eco-friendly advantages of PLA make it a preferred choice for sustainable packaging compared to conventional PET.

Common Applications of PET and PLA

PET (Polyethylene Terephthalate) is widely used in beverage bottles, food packaging, and synthetic fibers due to its strong barrier properties and recyclability. PLA (Polylactic Acid) finds common applications in compostable food containers, disposable cutlery, and medical implants thanks to its biodegradability and biocompatibility. Both materials serve distinct market needs, with PET favored for durability and PLA preferred for sustainable, eco-friendly products.

Mechanical Properties Comparison

PET exhibits superior tensile strength and impact resistance compared to PLA, making it more suitable for applications requiring durability and mechanical stress. PLA, while biodegradable, has lower flexibility and a lower melting point, limiting its use in high-temperature or high-stress environments. The stiffness of PET coupled with its resistance to deformation under load contrasts with PLA's brittleness and tendency to fracture under mechanical strain.

Recyclability: PET vs PLA

PET (Polyethylene Terephthalate) is widely accepted in recycling programs due to its efficient and high-quality recyclability, leading to the production of recycled PET (rPET) used in new containers and textiles. PLA (Polylactic Acid), a biodegradable plastic derived from renewable resources, faces significant challenges in recycling because it requires industrial composting facilities and often contaminates traditional plastic recycling streams. The established infrastructure for PET recycling far exceeds that of PLA, making PET more advantageous for circular economy goals in plastic waste management.

Cost Efficiency and Production Processes

PET (Polyethylene Terephthalate) offers greater cost efficiency due to its widespread availability and established large-scale production processes, enabling lower material and manufacturing expenses. PLA (Polylactic Acid), derived from renewable resources, tends to have higher production costs because of its fermentation-based synthesis and less mature manufacturing infrastructure. PET's compatibility with existing recycling systems further enhances overall cost-effectiveness in production and waste management compared to PLA.

Safety and Food Contact Considerations

PET (Polyethylene Terephthalate) is widely recognized for its safety in food contact applications due to its strong barrier properties, chemical resistance, and FDA approval for direct food contact. PLA (Polylactic Acid), a bioplastic derived from renewable resources, offers biodegradability but has lower heat resistance and may release lactic acid under high temperatures, raising concerns in hot food packaging. Regulatory guidelines emphasize PET's reliability for long-term food storage, while PLA is recommended for short-term, cold food contact to ensure consumer safety and maintain food quality.

Future Trends: Innovations in PET and PLA

Future trends in PET (polyethylene terephthalate) emphasize enhanced recyclability and the development of bio-based PET variants to reduce carbon footprints. Innovations in PLA (polylactic acid) target improved mechanical properties and accelerated compostability through advanced polymer blending and enzymatic degradation techniques. Both materials are converging towards sustainable packaging solutions driven by consumer demand and regulatory pressure for eco-friendly plastics.

PET vs PLA Infographic

materialdif.com

materialdif.com