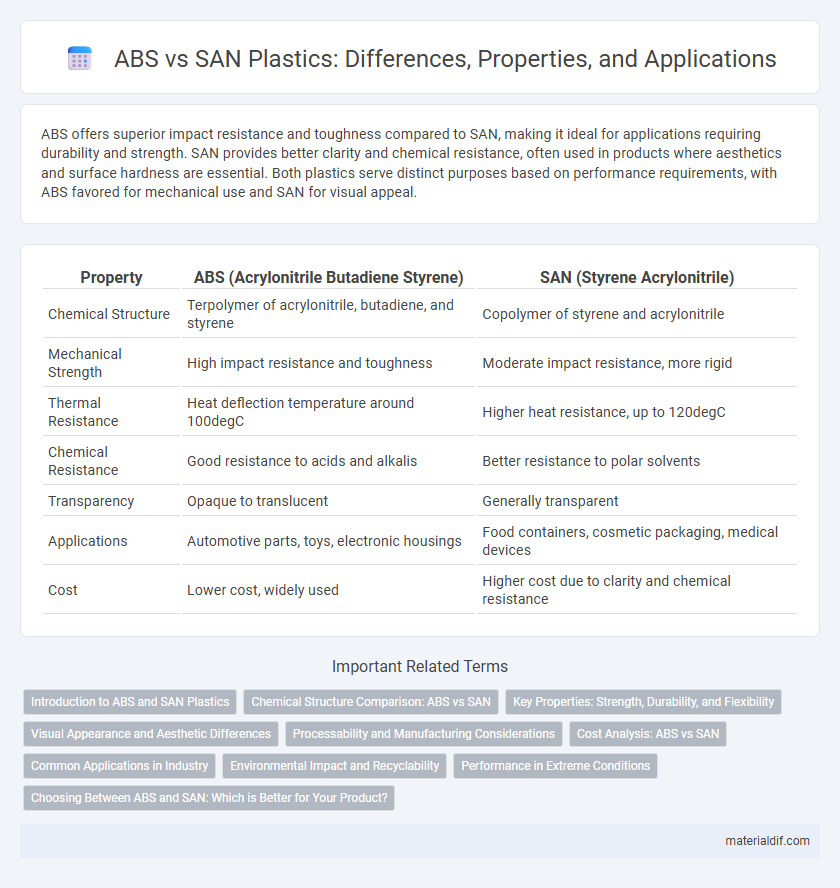

ABS offers superior impact resistance and toughness compared to SAN, making it ideal for applications requiring durability and strength. SAN provides better clarity and chemical resistance, often used in products where aesthetics and surface hardness are essential. Both plastics serve distinct purposes based on performance requirements, with ABS favored for mechanical use and SAN for visual appeal.

Table of Comparison

| Property | ABS (Acrylonitrile Butadiene Styrene) | SAN (Styrene Acrylonitrile) |

|---|---|---|

| Chemical Structure | Terpolymer of acrylonitrile, butadiene, and styrene | Copolymer of styrene and acrylonitrile |

| Mechanical Strength | High impact resistance and toughness | Moderate impact resistance, more rigid |

| Thermal Resistance | Heat deflection temperature around 100degC | Higher heat resistance, up to 120degC |

| Chemical Resistance | Good resistance to acids and alkalis | Better resistance to polar solvents |

| Transparency | Opaque to translucent | Generally transparent |

| Applications | Automotive parts, toys, electronic housings | Food containers, cosmetic packaging, medical devices |

| Cost | Lower cost, widely used | Higher cost due to clarity and chemical resistance |

Introduction to ABS and SAN Plastics

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic known for its toughness, impact resistance, and ease of machining, making it ideal for automotive parts, consumer electronics, and toys. SAN (Styrene Acrylonitrile) is a transparent, rigid thermoplastic with good chemical resistance and superior surface finish, often used in household appliances and medical devices. Both ABS and SAN offer unique benefits in plastic manufacturing, with ABS excelling in durability and SAN preferred for clarity and chemical stability.

Chemical Structure Comparison: ABS vs SAN

ABS (Acrylonitrile Butadiene Styrene) consists of three monomers--acrylonitrile, butadiene, and styrene--where butadiene imparts impact resistance and rubber-like flexibility. SAN (Styrene Acrylonitrile) is a copolymer made from styrene and acrylonitrile, lacking the butadiene component, resulting in higher rigidity and chemical resistance but reduced toughness. The key chemical structure difference lies in the presence of the butadiene rubber phase in ABS, which enhances impact strength compared to the rigid, more brittle SAN copolymer.

Key Properties: Strength, Durability, and Flexibility

ABS (Acrylonitrile Butadiene Styrene) exhibits excellent impact resistance, high strength, and notable toughness, making it highly durable for various applications. SAN (Styrene Acrylonitrile) offers superior rigidity and chemical resistance but has lower impact strength compared to ABS, resulting in less flexibility. The choice between ABS and SAN depends on the required balance between strength, durability, and flexibility for specific product needs.

Visual Appearance and Aesthetic Differences

ABS offers a glossy, smooth surface with excellent color richness and a high-quality finish, making it ideal for consumer electronics and automotive parts where visual appeal is critical. SAN, on the other hand, provides a clearer, more transparent appearance with a glass-like aesthetic, often used in applications requiring light diffusion or see-through elements such as display cases or cosmetic packaging. The choice between ABS and SAN largely depends on whether opacity with vibrant coloration or transparency with a glossy finish is desired for the final product's visual impact.

Processability and Manufacturing Considerations

ABS offers superior processability with enhanced impact resistance and ease of molding, making it ideal for injection molding and extrusion in complex shapes. SAN provides better heat resistance and surface finish but is more brittle and requires careful temperature control during manufacturing to prevent stress cracking. Manufacturers choose ABS for durability and versatility, while SAN is selected for applications demanding a smoother finish and higher dimensional stability.

Cost Analysis: ABS vs SAN

ABS (Acrylonitrile Butadiene Styrene) typically offers a lower material cost compared to SAN (Styrene Acrylonitrile), making it a more cost-effective option for high-volume production. SAN provides better chemical resistance and optical clarity, but these benefits come at a higher price point, impacting overall project budgets. Cost analysis between ABS and SAN should consider not only raw material pricing but also application-specific requirements and processing expenses.

Common Applications in Industry

ABS (Acrylonitrile Butadiene Styrene) is widely used in automotive parts, electronic housings, and consumer goods due to its impact resistance and ease of machining. SAN (Styrene Acrylonitrile) finds common applications in appliance parts, medical devices, and cosmetic containers because of its superior chemical resistance and clarity. Both plastics serve critical roles in manufacturing, with ABS preferred for durability and SAN favored for aesthetic and chemical stability in industrial products.

Environmental Impact and Recyclability

ABS (Acrylonitrile Butadiene Styrene) and SAN (Styrene Acrylonitrile) differ in environmental impact and recyclability, with ABS being less eco-friendly due to its butadiene content, which complicates recycling and leads to higher carbon emissions during production. SAN, composed mainly of styrene and acrylonitrile, tends to have better recyclability as it can be more easily processed in existing plastic recycling streams with lower environmental toxicity. Both materials contribute to plastic pollution, but SAN's simpler chemical structure offers a marginal advantage in reducing environmental footprint and enhancing circular economy potential.

Performance in Extreme Conditions

ABS (Acrylonitrile Butadiene Styrene) exhibits superior impact resistance and toughness in extreme temperature fluctuations, maintaining durability in both cold and moderately high-temperature environments. SAN (Styrene Acrylonitrile) offers enhanced chemical resistance and dimensional stability but tends to become brittle under very low temperatures and may deform under sustained high heat. For applications requiring resilience against mechanical stress and thermal shock, ABS outperforms SAN in maintaining structural integrity and performance.

Choosing Between ABS and SAN: Which is Better for Your Product?

ABS offers superior impact resistance and durability, making it ideal for applications requiring toughness and heat resistance, such as automotive parts and electronic housings. SAN provides better clarity, chemical resistance, and surface hardness, suitable for transparent or decorative components like appliance panels and consumer goods. Choosing between ABS and SAN depends on your product's specific needs for mechanical strength versus optical clarity and chemical durability.

ABS vs SAN Infographic

materialdif.com

materialdif.com