Nylon film offers greater flexibility and is ideal for applications requiring thin, lightweight, and transparent materials, whereas nylon sheet provides superior rigidity and durability for more structural uses. Nylon sheets typically have higher impact resistance and thickness options, making them suitable for machining and fabrication into robust parts. Both materials share excellent chemical resistance and tensile strength but differ significantly in their form factor and application versatility.

Table of Comparison

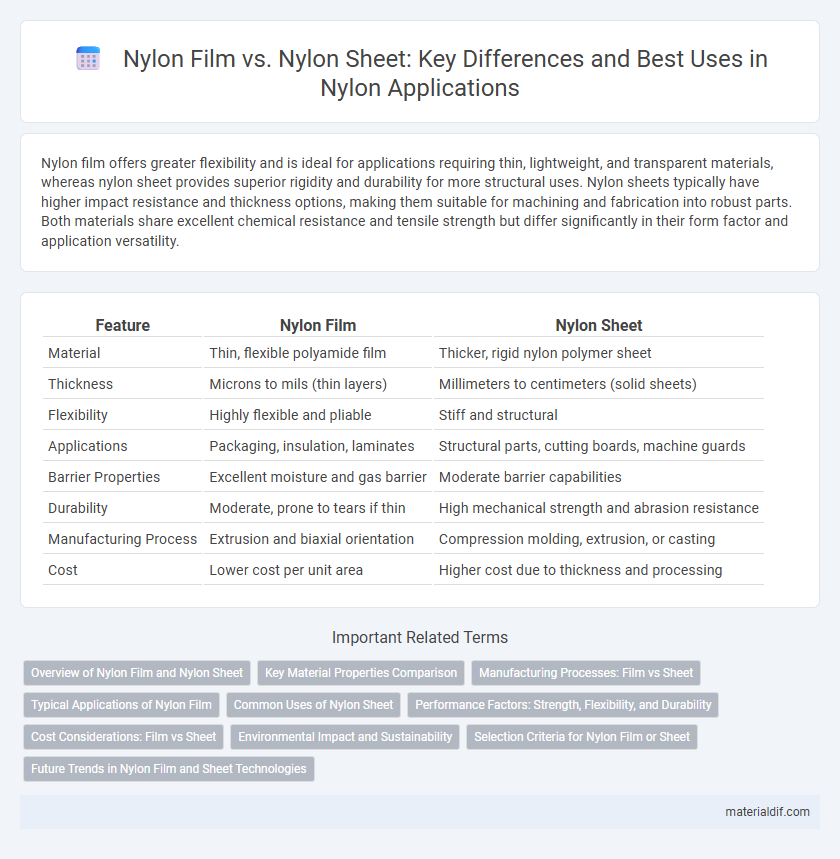

| Feature | Nylon Film | Nylon Sheet |

|---|---|---|

| Material | Thin, flexible polyamide film | Thicker, rigid nylon polymer sheet |

| Thickness | Microns to mils (thin layers) | Millimeters to centimeters (solid sheets) |

| Flexibility | Highly flexible and pliable | Stiff and structural |

| Applications | Packaging, insulation, laminates | Structural parts, cutting boards, machine guards |

| Barrier Properties | Excellent moisture and gas barrier | Moderate barrier capabilities |

| Durability | Moderate, prone to tears if thin | High mechanical strength and abrasion resistance |

| Manufacturing Process | Extrusion and biaxial orientation | Compression molding, extrusion, or casting |

| Cost | Lower cost per unit area | Higher cost due to thickness and processing |

Overview of Nylon Film and Nylon Sheet

Nylon film offers superior flexibility and clarity, making it ideal for packaging applications requiring moisture resistance and puncture strength, while nylon sheets provide robust structural support with higher thickness and rigidity for industrial and mechanical uses. Nylon films typically range from 12 to 100 microns in thickness, enabling lightweight, transparent layers, whereas nylon sheets are available in millimeter thicknesses, offering durability and impact resistance. Material properties like excellent wear resistance, chemical stability, and thermal resistance are inherent in both forms, but their applications differ based on physical form and mechanical strength.

Key Material Properties Comparison

Nylon film offers superior flexibility, clarity, and moisture barrier properties, making it ideal for packaging and industrial applications requiring lightweight and transparent material. Nylon sheets provide enhanced mechanical strength, impact resistance, and dimensional stability, suitable for structural components and parts subjected to higher stress. Both materials exhibit excellent chemical resistance and thermal stability, but their distinct form factors dictate their optimal uses in manufacturing.

Manufacturing Processes: Film vs Sheet

Nylon film is produced through a casting or extrusion process that creates thin, flexible layers ideal for packaging and protective coatings. In contrast, nylon sheet is typically manufactured by compression molding or extrusion followed by calendaring, resulting in thicker, rigid materials used for structural applications. The distinct manufacturing techniques directly influence the mechanical properties and end-use performance of nylon films versus sheets.

Typical Applications of Nylon Film

Nylon film is widely used in flexible packaging, food preservation, and industrial applications due to its excellent barrier properties against oxygen and moisture. It is commonly employed in vacuum packaging, snack food bags, and medical packaging where transparency and durability are critical. Unlike nylon sheets, which are rigid and suited for mechanical parts or structural components, nylon film offers superior flexibility and clarity for protective and wrapping solutions.

Common Uses of Nylon Sheet

Nylon sheets are commonly used in engineering applications such as gears, bearings, and wear plates due to their high strength, durability, and excellent abrasion resistance. Unlike nylon film, which is primarily utilized for packaging and electrical insulation, nylon sheets provide structural support and are often fabricated into custom parts for industrial machinery. Their chemical resistance and low friction properties make them ideal for automotive, construction, and manufacturing industries.

Performance Factors: Strength, Flexibility, and Durability

Nylon film offers superior flexibility and lightweight properties, making it ideal for applications requiring thin, durable barriers with excellent tensile strength. Nylon sheets provide enhanced structural strength and impact resistance, suitable for heavy-duty uses where rigidity and long-term durability are crucial. Both materials exhibit high abrasion resistance and chemical stability, but the choice depends on balancing flexibility needs with load-bearing requirements.

Cost Considerations: Film vs Sheet

Nylon film generally offers a lower cost per square foot compared to nylon sheet, making it more economical for applications requiring thin, flexible material. However, nylon sheets provide greater thickness and durability at a higher price point, justifying the investment for projects demanding structural strength. Cost efficiency depends on the specific thickness and mechanical properties needed for the intended use.

Environmental Impact and Sustainability

Nylon film offers enhanced recyclability due to its thinner gauge, reducing raw material consumption and energy use compared to thicker nylon sheets. Nylon sheets, while durable, typically require more resources to produce and generate more waste at end-of-life, negatively impacting environmental sustainability. Choosing nylon film supports reduced carbon footprint and waste, aligning better with eco-friendly manufacturing practices.

Selection Criteria for Nylon Film or Sheet

Nylon film offers superior flexibility, chemical resistance, and moisture barrier properties, making it ideal for packaging applications requiring transparency and lightweight durability. Nylon sheets provide greater rigidity, impact resistance, and structural support, suitable for engineering components and mechanical uses. Selection between nylon film and sheet depends primarily on the required thickness, mechanical strength, and application environment, with film favored for flexible packaging and sheets chosen for robust, load-bearing applications.

Future Trends in Nylon Film and Sheet Technologies

Advancements in nylon film and sheet technologies are driven by increased demand for lightweight, high-strength, and sustainable materials in packaging, automotive, and electronics industries. Emerging trends include enhanced barrier properties, improved recyclability, and integration of nanomaterials to boost mechanical and thermal performance. Innovation in bio-based nylon films and sheets is accelerating to meet stringent environmental regulations and consumer preference for eco-friendly solutions.

Nylon Film vs Nylon Sheet Infographic

materialdif.com

materialdif.com