Nylon mesh offers superior breathability and flexibility, making it ideal for applications requiring ventilation and lightweight durability. In contrast, nylon solid sheets provide enhanced strength, rigidity, and resistance to impact, suited for structural or protective uses. Choosing between nylon mesh and solid sheets depends on specific performance requirements such as airflow versus mechanical strength.

Table of Comparison

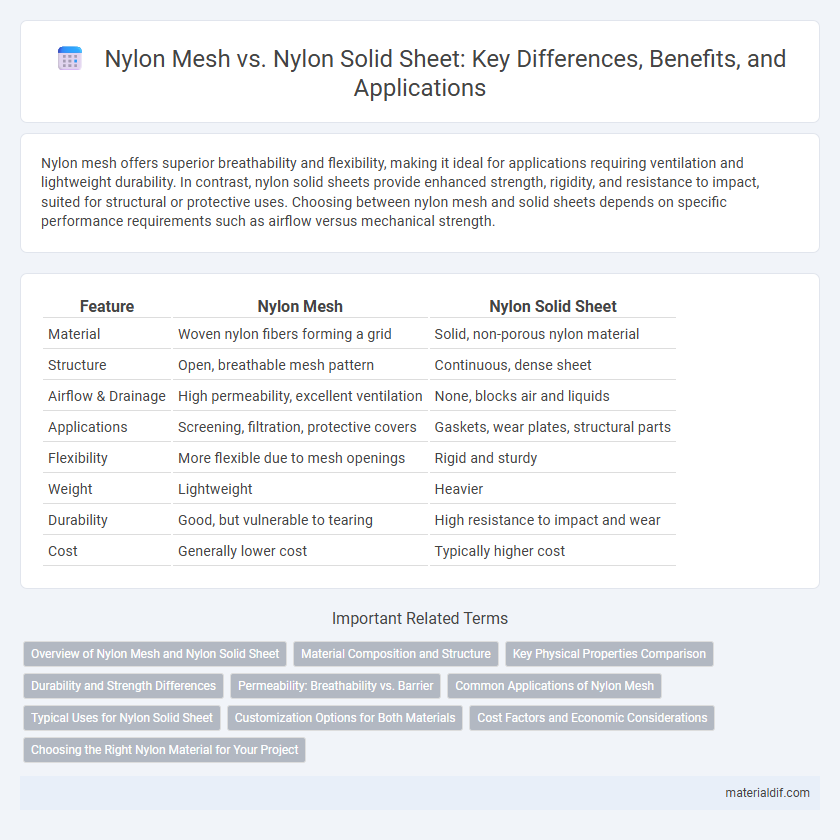

| Feature | Nylon Mesh | Nylon Solid Sheet |

|---|---|---|

| Material | Woven nylon fibers forming a grid | Solid, non-porous nylon material |

| Structure | Open, breathable mesh pattern | Continuous, dense sheet |

| Airflow & Drainage | High permeability, excellent ventilation | None, blocks air and liquids |

| Applications | Screening, filtration, protective covers | Gaskets, wear plates, structural parts |

| Flexibility | More flexible due to mesh openings | Rigid and sturdy |

| Weight | Lightweight | Heavier |

| Durability | Good, but vulnerable to tearing | High resistance to impact and wear |

| Cost | Generally lower cost | Typically higher cost |

Overview of Nylon Mesh and Nylon Solid Sheet

Nylon mesh features an open grid structure that provides excellent ventilation, flexibility, and lightweight strength, making it ideal for filtration, screening, and protective applications. Nylon solid sheets offer a dense, non-perforated surface with high tensile strength, impact resistance, and chemical durability, suitable for structural components, wear pads, and insulating layers. Both materials leverage nylon's inherent resistance to abrasion, moisture, and chemicals, but their physical forms cater to distinct industrial uses based on permeability and solidity requirements.

Material Composition and Structure

Nylon mesh consists of interwoven nylon fibers creating a porous structure that allows air and liquids to pass through, making it ideal for filtration and screening applications. Nylon solid sheets are made from dense, uniformly molded nylon resin, providing high tensile strength, impact resistance, and abrasion durability. The material composition in both forms is primarily polyamide, but the structural difference significantly influences their functional properties.

Key Physical Properties Comparison

Nylon mesh offers superior breathability and flexibility compared to nylon solid sheets, which provide enhanced strength and rigidity. The open structure of nylon mesh ensures excellent airflow and reduced weight, making it ideal for filtration and lightweight enclosures. In contrast, nylon solid sheets exhibit higher tensile strength, impact resistance, and durability, suitable for demanding mechanical applications requiring robust protection.

Durability and Strength Differences

Nylon mesh offers enhanced flexibility and breathability, making it suitable for applications requiring ventilation and lightweight durability. Nylon solid sheets provide greater strength and impact resistance due to their dense, uniform structure, ideal for heavy-duty protection and structural support. The choice between nylon mesh and solid sheets depends on specific durability needs, with solid sheets excelling in load-bearing strength and mesh prioritizing flexibility and airflow.

Permeability: Breathability vs. Barrier

Nylon mesh offers superior permeability, allowing excellent breathability and airflow, making it ideal for applications requiring ventilation and moisture escape. In contrast, nylon solid sheets provide a strong barrier against liquids, dust, and contaminants, ensuring protection and durability in sealing or protective covers. The choice between nylon mesh and solid sheets depends on whether breathability or barrier performance is the primary requirement for the intended use.

Common Applications of Nylon Mesh

Nylon mesh is widely used in filtration, screening, and protective gear due to its breathable structure and durability, enabling efficient air and liquid flow while blocking debris. Common applications include window screens, insect nets, and industrial filters, where its flexibility and resistance to chemicals provide long-lasting performance. In contrast, nylon solid sheets are preferred for structural components, wear pads, and mechanical parts requiring high impact strength and abrasion resistance.

Typical Uses for Nylon Solid Sheet

Nylon solid sheets are commonly used in manufacturing components that require high strength and wear resistance, such as gears, bushings, and structural parts. Their dense, non-porous composition provides excellent impact resistance and low friction, making them ideal for mechanical and industrial applications. These sheets are also favored for their chemical resistance and ease of machining in custom fabrication projects.

Customization Options for Both Materials

Nylon mesh offers extensive customization options including varied mesh sizes, porosity levels, and thicknesses to suit filtration, screening, or reinforcement applications. Nylon solid sheets provide flexibility in thickness, color, and surface finish, enabling tailored solutions for impact resistance, wear protection, and structural components. Both materials can be precision-cut and shaped, allowing for intricate designs and specific functional requirements across industrial and commercial uses.

Cost Factors and Economic Considerations

Nylon mesh typically incurs lower initial costs compared to nylon solid sheets due to reduced material usage and lighter weight, making it cost-effective for applications requiring filtration or ventilation. Solid nylon sheets, while more expensive upfront, offer greater durability and structural integrity, which can lead to lower replacement frequency and long-term savings in high-impact or load-bearing environments. Economic considerations often hinge on application-specific needs, where mesh suits budget-conscious projects focused on airflow and transparency, while solid sheets justify higher expenses through enhanced strength and longevity.

Choosing the Right Nylon Material for Your Project

Nylon mesh offers superior airflow and drainage, making it ideal for applications like filtration, screening, or protective coverings, whereas nylon solid sheets provide strength, durability, and resistance to wear, suitable for structural components and impact protection. Consider project requirements such as flexibility, permeability, and load-bearing capacity when selecting between nylon mesh and solid sheets. Optimizing material choice based on specific environmental conditions and mechanical demands ensures enhanced performance and longevity.

Nylon Mesh vs Nylon Solid Sheet Infographic

materialdif.com

materialdif.com