Heat stabilized nylon offers enhanced resistance to thermal degradation, maintaining its mechanical properties and dimensional stability under high temperatures compared to unstabilized nylon. Unstabilized nylon tends to absorb moisture and degrade faster when exposed to heat, leading to reduced strength and increased brittleness over time. Choosing heat stabilized nylon ensures superior durability and longevity in applications subjected to continuous or fluctuating heat conditions.

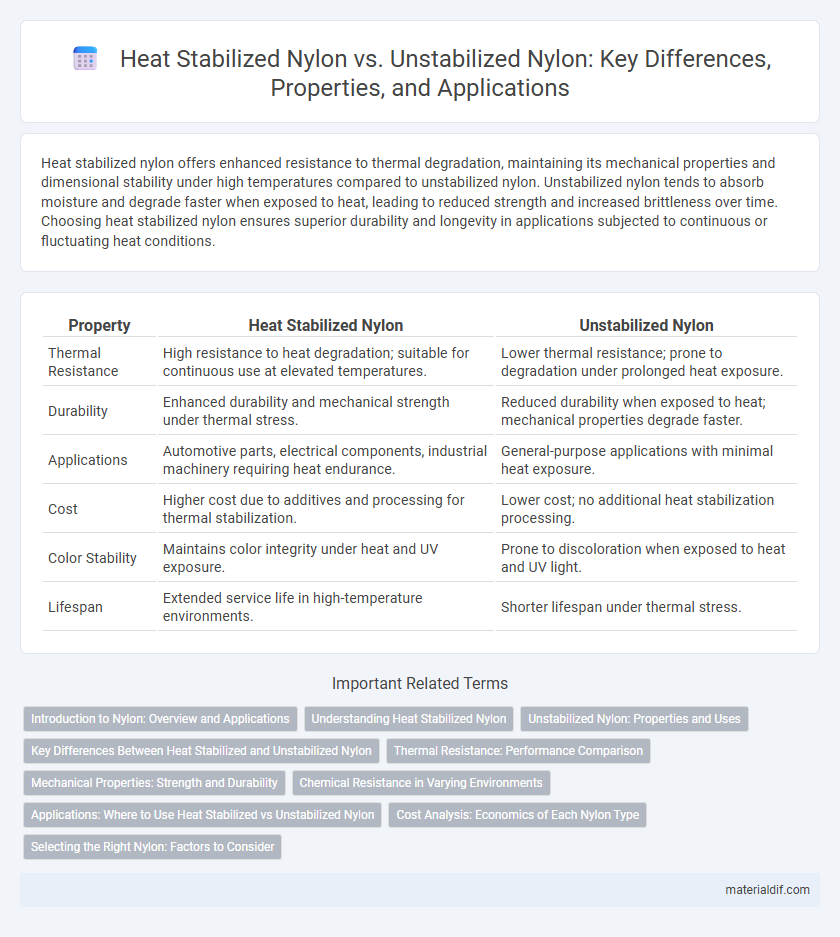

Table of Comparison

| Property | Heat Stabilized Nylon | Unstabilized Nylon |

|---|---|---|

| Thermal Resistance | High resistance to heat degradation; suitable for continuous use at elevated temperatures. | Lower thermal resistance; prone to degradation under prolonged heat exposure. |

| Durability | Enhanced durability and mechanical strength under thermal stress. | Reduced durability when exposed to heat; mechanical properties degrade faster. |

| Applications | Automotive parts, electrical components, industrial machinery requiring heat endurance. | General-purpose applications with minimal heat exposure. |

| Cost | Higher cost due to additives and processing for thermal stabilization. | Lower cost; no additional heat stabilization processing. |

| Color Stability | Maintains color integrity under heat and UV exposure. | Prone to discoloration when exposed to heat and UV light. |

| Lifespan | Extended service life in high-temperature environments. | Shorter lifespan under thermal stress. |

Introduction to Nylon: Overview and Applications

Heat stabilized nylon resists thermal degradation, extending its performance in high-temperature applications such as automotive under-the-hood components and electrical insulators. Unstabilized nylon exhibits vulnerability to heat, limiting its use to low-heat environments like textile fibers and consumer goods. Understanding the thermal properties of nylon variants guides material selection for engineering and industrial design.

Understanding Heat Stabilized Nylon

Heat stabilized nylon is engineered to resist thermal degradation and maintain mechanical properties under elevated temperatures, often achieved by adding specific heat stabilizers during the polymerization process. This modification enhances the material's resistance to discoloration, brittleness, and loss of tensile strength compared to unstabilized nylon, making it ideal for high-temperature applications in automotive and electrical components. Selecting heat stabilized nylon improves long-term durability and performance in environments exposed to continuous heat or thermal cycling.

Unstabilized Nylon: Properties and Uses

Unstabilized nylon exhibits high tensile strength, excellent flexibility, and good abrasion resistance, making it suitable for applications where heat exposure is minimal. It tends to degrade and lose mechanical properties when subjected to elevated temperatures or prolonged UV radiation, limiting its use in harsh environments. Common uses include textile fibers, fishing lines, and injection-molded parts in consumer products where heat stabilization is not critical.

Key Differences Between Heat Stabilized and Unstabilized Nylon

Heat stabilized nylon exhibits enhanced resistance to thermal degradation, maintaining its mechanical properties at elevated temperatures compared to unstabilized nylon, which tends to weaken and deform under heat exposure. The incorporation of heat stabilizers in nylon reduces discoloration, improves dimensional stability, and prevents hydrolysis during prolonged thermal processing. Unstabilized nylon's susceptibility to heat-induced molecular breakdown limits its use in high-temperature applications, whereas heat stabilized variants ensure durability and performance in demanding environments.

Thermal Resistance: Performance Comparison

Heat stabilized nylon exhibits significantly higher thermal resistance than unstabilized nylon, maintaining mechanical strength and dimensional stability at temperatures above 150degC. Unstabilized nylon tends to degrade and lose structural integrity when exposed to prolonged heat, typically starting at around 120degC. The thermal stabilization additives in heat stabilized nylon inhibit oxidation and thermal decomposition, extending its service life in high-temperature applications.

Mechanical Properties: Strength and Durability

Heat stabilized nylon exhibits enhanced mechanical properties, with significantly increased tensile strength and improved resistance to thermal degradation compared to unstabilized nylon. This stabilization process helps maintain the polymer's molecular structure under high temperatures, leading to superior durability and long-lasting performance in demanding applications. Unstabilized nylon tends to weaken and lose mechanical integrity more quickly when exposed to heat, limiting its use in high-stress environments.

Chemical Resistance in Varying Environments

Heat stabilized nylon exhibits superior chemical resistance compared to unstabilized nylon, maintaining structural integrity in harsh environments such as exposure to acids, alkalis, and solvents. Its enhanced thermal stability prevents degradation when subjected to elevated temperatures and aggressive chemical agents common in industrial applications. Unstabilized nylon, by contrast, is prone to hydrolysis and chemical breakdown, limiting its use in demanding chemical environments and shortening its service life.

Applications: Where to Use Heat Stabilized vs Unstabilized Nylon

Heat stabilized nylon is ideal for applications involving prolonged exposure to high temperatures, such as automotive engine components, electrical connectors, and industrial machinery parts, where thermal degradation resistance is critical. Unstabilized nylon suits lower temperature uses like consumer goods, textiles, and general-purpose molded parts where heat exposure is minimal and cost efficiency is prioritized. Selecting heat stabilized nylon ensures durability and performance in heat-intensive environments, while unstabilized nylon offers flexibility and lower cost for less demanding conditions.

Cost Analysis: Economics of Each Nylon Type

Heat stabilized nylon incurs higher production costs due to additives and processing required to enhance thermal resistance, resulting in increased material expenses but improved durability in high-temperature applications. Unstabilized nylon offers lower initial cost, making it suitable for budget-sensitive projects with minimal exposure to heat stress, but it may lead to higher long-term costs due to faster degradation and replacement needs. Economic analysis favors heat stabilized nylon for applications demanding extended lifespan and reduced maintenance, while unstabilized nylon remains cost-effective for low-heat environments.

Selecting the Right Nylon: Factors to Consider

Heat stabilized nylon offers enhanced resistance to thermal degradation, making it ideal for applications involving continuous exposure to elevated temperatures above 120degC. In contrast, unstabilized nylon is suitable for lower temperature environments where cost-effectiveness and flexibility are prioritized over thermal resistance. Key factors in selecting the right nylon include operating temperature, mechanical load, exposure to chemicals, and environmental conditions to ensure durability and performance.

Heat Stabilized Nylon vs Unstabilized Nylon Infographic

materialdif.com

materialdif.com