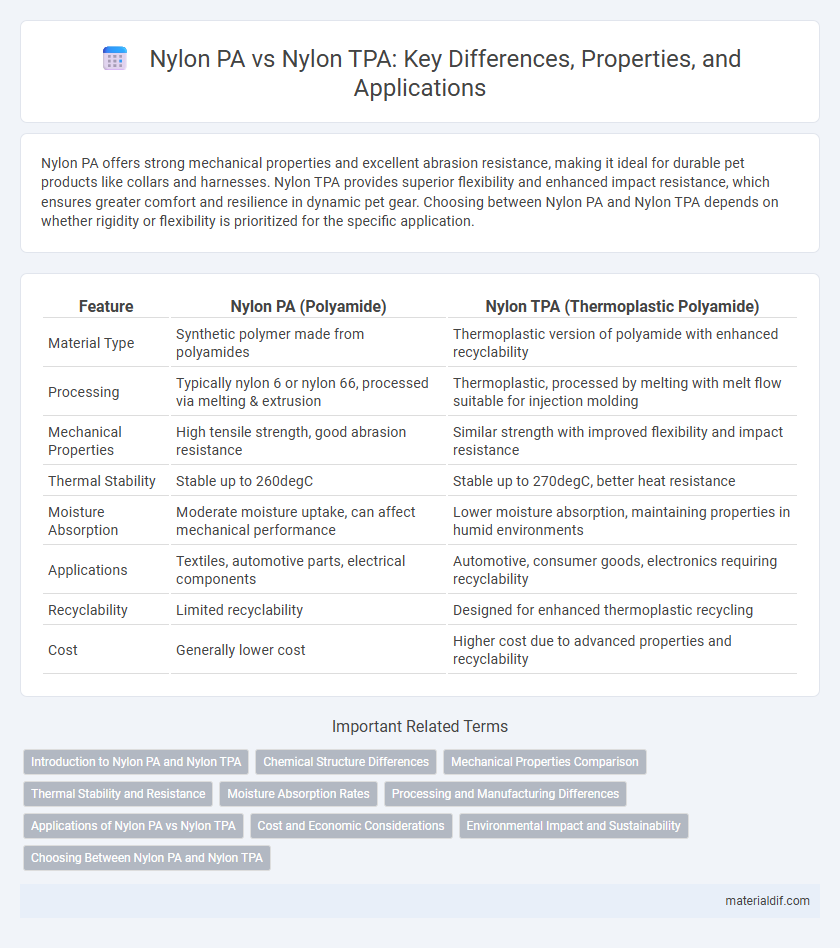

Nylon PA offers strong mechanical properties and excellent abrasion resistance, making it ideal for durable pet products like collars and harnesses. Nylon TPA provides superior flexibility and enhanced impact resistance, which ensures greater comfort and resilience in dynamic pet gear. Choosing between Nylon PA and Nylon TPA depends on whether rigidity or flexibility is prioritized for the specific application.

Table of Comparison

| Feature | Nylon PA (Polyamide) | Nylon TPA (Thermoplastic Polyamide) |

|---|---|---|

| Material Type | Synthetic polymer made from polyamides | Thermoplastic version of polyamide with enhanced recyclability |

| Processing | Typically nylon 6 or nylon 66, processed via melting & extrusion | Thermoplastic, processed by melting with melt flow suitable for injection molding |

| Mechanical Properties | High tensile strength, good abrasion resistance | Similar strength with improved flexibility and impact resistance |

| Thermal Stability | Stable up to 260degC | Stable up to 270degC, better heat resistance |

| Moisture Absorption | Moderate moisture uptake, can affect mechanical performance | Lower moisture absorption, maintaining properties in humid environments |

| Applications | Textiles, automotive parts, electrical components | Automotive, consumer goods, electronics requiring recyclability |

| Recyclability | Limited recyclability | Designed for enhanced thermoplastic recycling |

| Cost | Generally lower cost | Higher cost due to advanced properties and recyclability |

Introduction to Nylon PA and Nylon TPA

Nylon PA, or Polyamide, is a widely used synthetic polymer known for its high strength, abrasion resistance, and excellent chemical stability, commonly applied in textiles and industrial components. Nylon TPA, a variant of nylon based on thermoplastic polyamide, offers enhanced thermal resistance and mechanical properties suitable for advanced engineering applications. Understanding the distinctions between Nylon PA and Nylon TPA is crucial for selecting the appropriate material in sectors like automotive, aerospace, and consumer goods manufacturing.

Chemical Structure Differences

Nylon PA (Polyamide) consists of repeating amide groups linked by aliphatic chains, forming a linear polymer with high flexibility and strength. Nylon TPA (Thermoplastic Polyamide) incorporates aromatic rings within its polymer backbone, enhancing thermal stability and rigidity compared to conventional Nylon PA. The presence of these aromatic structures in Nylon TPA alters chain packing and intermolecular forces, resulting in distinct mechanical and thermal properties.

Mechanical Properties Comparison

Nylon PA (Polyamide) offers excellent tensile strength and abrasion resistance, making it suitable for demanding mechanical applications, while Nylon TPA (Thermoplastic Polyamide) provides enhanced flexibility and improved impact resistance due to its unique copolymer structure. Nylon PA typically demonstrates higher stiffness and hardness compared to Nylon TPA, which exhibits better elongation at break and resilience under dynamic loading. Selecting between Nylon PA and Nylon TPA depends on specific mechanical property requirements such as rigidity versus flexibility and wear resistance versus impact absorption.

Thermal Stability and Resistance

Nylon PA exhibits moderate thermal stability with a melting point typically around 220-265degC, making it suitable for applications requiring basic heat resistance. In comparison, Nylon TPA (Thermoplastic Polyester Amide) offers superior thermal stability and enhanced heat resistance, often withstanding temperatures above 270degC due to its combined polyester and amide structure. This makes Nylon TPA more resistant to thermal degradation and dimensional changes under prolonged heat exposure than conventional Nylon PA.

Moisture Absorption Rates

Nylon PA exhibits a moisture absorption rate typically around 2.3% to 2.8%, which can affect its dimensional stability and mechanical properties in humid environments. In contrast, Nylon TPA (Thermoplastic Polyamide) generally absorbs less moisture, with rates closer to 1.5% to 2.0%, offering improved resistance to water uptake and better performance in applications requiring lower moisture sensitivity. Understanding these differences is crucial for selecting the appropriate material in industries such as automotive, electronics, and textiles where moisture exposure impacts durability and functionality.

Processing and Manufacturing Differences

Nylon PA (Polyamide) typically requires higher processing temperatures around 260-280degC due to its semi-crystalline structure, while Nylon TPA (Thermoplastic Polyamide) processes efficiently at slightly lower temperatures of 230-260degC, enhancing energy efficiency. Injection molding of Nylon PA demands precise moisture conditioning to avoid hydrolytic degradation, whereas Nylon TPA exhibits improved moisture resistance, reducing pre-drying time and complexity. The crystallization behavior of Nylon PA leads to longer cycle times in manufacturing, compared to Nylon TPA's faster solidification rates, enabling higher production throughput.

Applications of Nylon PA vs Nylon TPA

Nylon PA, commonly used in automotive parts, textiles, and industrial machinery, offers excellent mechanical strength and chemical resistance suited for high-stress applications. Nylon TPA, favored in electrical and electronics components, provides superior thermal stability and dimensional accuracy, making it ideal for connectors, housings, and precision engineering parts. Both materials serve distinct industry needs with Nylon PA excelling in durability and Nylon TPA in temperature resilience.

Cost and Economic Considerations

Nylon PA generally offers lower production costs compared to Nylon TPA due to simpler manufacturing processes and widely available raw materials. Nylon TPA tends to have higher upfront costs but provides enhanced performance characteristics that can lead to longer product lifespans and reduced maintenance expenses. Evaluating the cost-benefit ratio of Nylon PA versus Nylon TPA involves considering both initial investment and total lifecycle economic impact.

Environmental Impact and Sustainability

Nylon PA (Polyamide) typically has a higher environmental impact due to its petroleum-based raw materials and energy-intensive production processes, resulting in greater greenhouse gas emissions and lower biodegradability. In contrast, Nylon TPA (Thermoplastic Polyamide) offers improved sustainability through enhanced recyclability and potential integration of bio-based feedstocks, reducing dependence on fossil fuels and promoting circular economy principles. Choosing Nylon TPA supports lower carbon footprints and waste reduction, making it a more eco-friendly option in textile and plastic manufacturing.

Choosing Between Nylon PA and Nylon TPA

Choosing between Nylon PA and Nylon TPA depends on the specific application requirements, as Nylon PA offers excellent mechanical strength and chemical resistance, while Nylon TPA provides superior thermal stability and flexibility. Nylon PA is commonly used in automotive parts, electrical components, and industrial machinery, whereas Nylon TPA is favored for high-temperature environments and dynamic applications such as sports equipment and flexible tubing. Evaluating factors like operating temperature, mechanical load, and environmental exposure helps determine the optimal nylon type for enhanced performance and durability.

Nylon PA vs Nylon TPA Infographic

materialdif.com

materialdif.com