UV-stabilized nylon offers enhanced resistance to degradation caused by prolonged exposure to sunlight, maintaining its strength and flexibility far longer than standard nylon. Unlike standard nylon, which can become brittle and lose performance properties when exposed to UV radiation, UV-stabilized nylon incorporates additives that prevent molecular breakdown. This makes UV-stabilized nylon ideal for outdoor pet products, ensuring durability and safety under harsh environmental conditions.

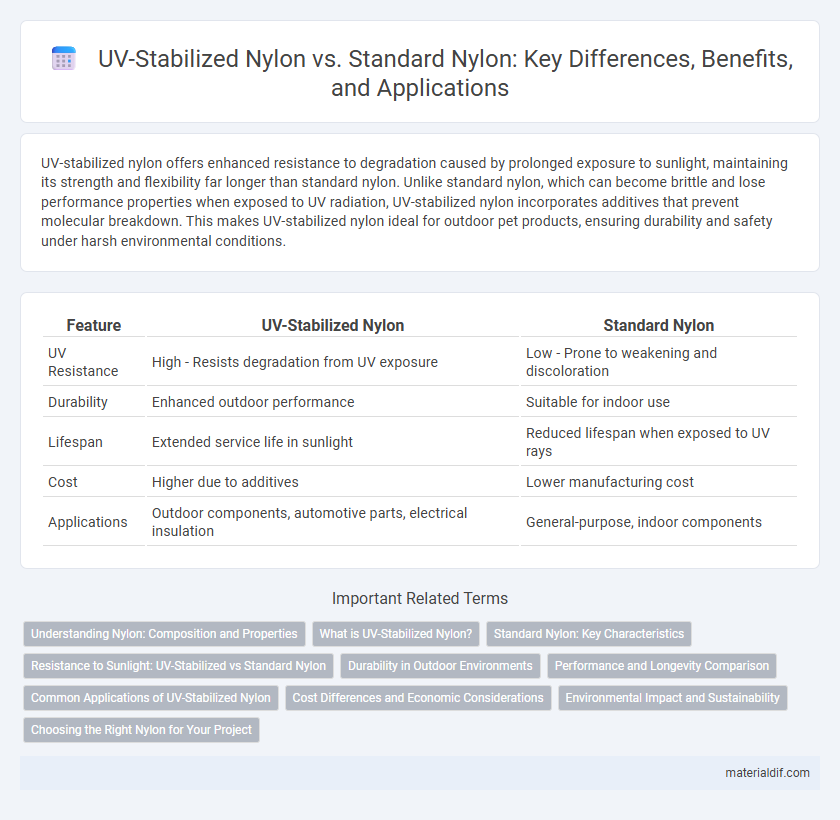

Table of Comparison

| Feature | UV-Stabilized Nylon | Standard Nylon |

|---|---|---|

| UV Resistance | High - Resists degradation from UV exposure | Low - Prone to weakening and discoloration |

| Durability | Enhanced outdoor performance | Suitable for indoor use |

| Lifespan | Extended service life in sunlight | Reduced lifespan when exposed to UV rays |

| Cost | Higher due to additives | Lower manufacturing cost |

| Applications | Outdoor components, automotive parts, electrical insulation | General-purpose, indoor components |

Understanding Nylon: Composition and Properties

UV-stabilized nylon incorporates additives like hindered amine light stabilizers (HALS) and UV absorbers to enhance resistance against ultraviolet radiation degradation, preserving mechanical strength and color integrity over prolonged sun exposure. Standard nylon, primarily composed of polyamides derived from hexamethylene diamine and adipic acid, offers excellent tensile strength, abrasion resistance, and chemical resistance but is susceptible to UV-induced oxidative chain scission, leading to embrittlement and discoloration. Understanding the molecular structure variations and additive integration clarifies how UV-stabilized nylon extends the lifespan and performance reliability in outdoor and high-UV environments compared to conventional nylon formulations.

What is UV-Stabilized Nylon?

UV-stabilized nylon is a modified form of standard nylon that incorporates additives to protect against ultraviolet (UV) radiation degradation. This enhancement significantly improves the material's resistance to discoloration, embrittlement, and loss of mechanical properties when exposed to prolonged sunlight. UV-stabilized nylon is essential for outdoor applications, ensuring durability and longevity compared to untreated standard nylon.

Standard Nylon: Key Characteristics

Standard nylon exhibits high tensile strength, excellent abrasion resistance, and good flexibility, making it suitable for various industrial and consumer applications. Its natural moisture absorption can lead to dimensional changes and reduced mechanical properties under prolonged exposure to humidity. Unlike UV-stabilized nylon, standard nylon degrades more rapidly when exposed to ultraviolet light, resulting in discoloration, brittleness, and loss of performance over time.

Resistance to Sunlight: UV-Stabilized vs Standard Nylon

UV-stabilized nylon incorporates additives that absorb and dissipate ultraviolet radiation, significantly enhancing its resistance to sunlight degradation compared to standard nylon. Standard nylon tends to yellow, weaken, and lose mechanical properties when exposed to prolonged UV exposure, leading to reduced lifespan and performance in outdoor applications. The UV-stabilized variant maintains structural integrity and color stability, making it ideal for outdoor use where sunlight resistance is critical.

Durability in Outdoor Environments

UV-stabilized nylon incorporates additives that significantly improve resistance to UV radiation, preventing degradation and maintaining strength in prolonged sun exposure compared to standard nylon. This enhanced durability makes UV-stabilized nylon ideal for outdoor applications such as marine hardware, outdoor gear, and automotive parts exposed to direct sunlight. Standard nylon tends to yellow, crack, and lose mechanical properties when subjected to UV rays, limiting its lifespan in outdoor environments.

Performance and Longevity Comparison

UV-stabilized nylon exhibits enhanced resistance to ultraviolet radiation, significantly reducing degradation, color fading, and loss of mechanical properties compared to standard nylon. This improved formulation extends the material's lifespan in outdoor applications by maintaining tensile strength, flexibility, and impact resistance under prolonged sun exposure. Consequently, UV-stabilized nylon outperforms standard nylon in terms of durability, making it ideal for products exposed to harsh environmental conditions.

Common Applications of UV-Stabilized Nylon

UV-stabilized nylon is engineered to withstand prolonged exposure to ultraviolet light, making it ideal for outdoor applications such as automotive components, electrical connectors, and marine hardware. Unlike standard nylon, which may degrade and lose strength when exposed to sunlight, UV-stabilized variants maintain their mechanical properties and resist yellowing or brittleness. This enhanced durability extends the lifespan of products used in harsh environments, including outdoor furniture, sports equipment, and agricultural machinery.

Cost Differences and Economic Considerations

UV-stabilized nylon typically incurs higher costs than standard nylon due to the addition of UV inhibitors and stabilizers that enhance weather resistance and prolong material lifespan in outdoor applications. While the upfront price difference can range from 15% to 30%, the extended durability and reduced maintenance requirements of UV-stabilized nylon often lead to lower total cost of ownership over time. Economic considerations favor UV-stabilized nylon for projects with long-term exposure to sunlight, balancing initial investment with improved performance and reduced replacement frequency.

Environmental Impact and Sustainability

UV-stabilized nylon extends material lifespan by reducing degradation from ultraviolet exposure, thereby minimizing waste and resource consumption compared to standard nylon. Its enhanced durability lowers the frequency of replacement, contributing to less environmental pollution and reduced carbon footprint throughout the product lifecycle. Incorporating UV stabilizers improves overall sustainability by optimizing nylon's performance in outdoor applications without relying heavily on frequent manufacturing cycles.

Choosing the Right Nylon for Your Project

UV-stabilized nylon offers enhanced resistance to ultraviolet light degradation, making it ideal for outdoor applications exposed to sunlight, whereas standard nylon may degrade faster under such conditions. Selecting the right nylon depends on the environmental exposure, mechanical strength requirements, and desired lifespan of the project. For critical outdoor parts like automotive components or outdoor gear, UV-stabilized nylon ensures longevity, while standard nylon suits indoor or shaded uses.

UV-Stabilized Nylon vs Standard Nylon Infographic

materialdif.com

materialdif.com