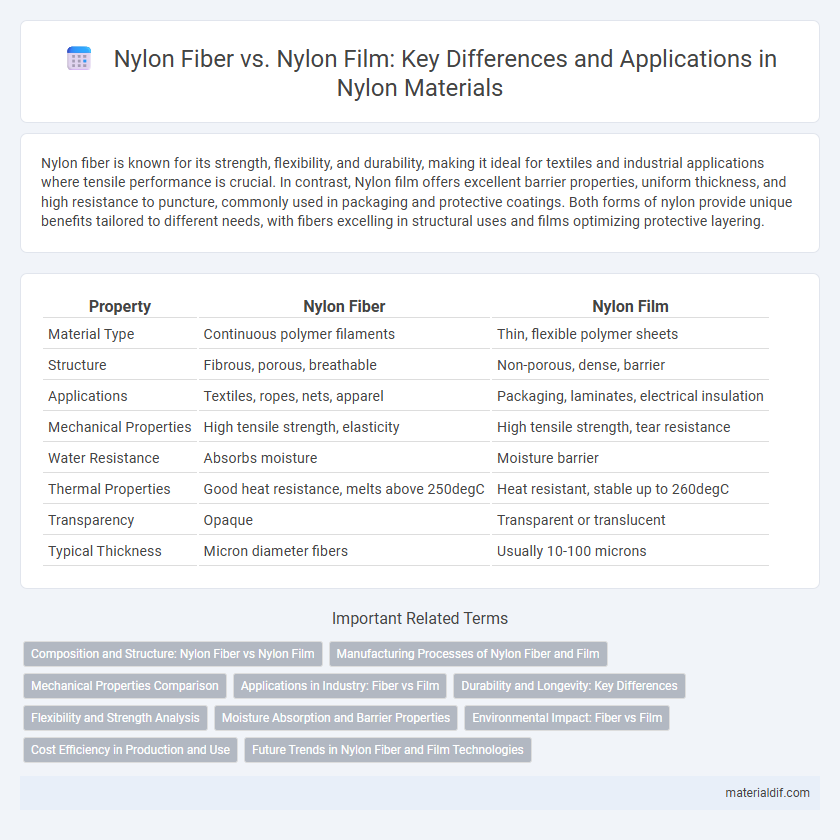

Nylon fiber is known for its strength, flexibility, and durability, making it ideal for textiles and industrial applications where tensile performance is crucial. In contrast, Nylon film offers excellent barrier properties, uniform thickness, and high resistance to puncture, commonly used in packaging and protective coatings. Both forms of nylon provide unique benefits tailored to different needs, with fibers excelling in structural uses and films optimizing protective layering.

Table of Comparison

| Property | Nylon Fiber | Nylon Film |

|---|---|---|

| Material Type | Continuous polymer filaments | Thin, flexible polymer sheets |

| Structure | Fibrous, porous, breathable | Non-porous, dense, barrier |

| Applications | Textiles, ropes, nets, apparel | Packaging, laminates, electrical insulation |

| Mechanical Properties | High tensile strength, elasticity | High tensile strength, tear resistance |

| Water Resistance | Absorbs moisture | Moisture barrier |

| Thermal Properties | Good heat resistance, melts above 250degC | Heat resistant, stable up to 260degC |

| Transparency | Opaque | Transparent or translucent |

| Typical Thickness | Micron diameter fibers | Usually 10-100 microns |

Composition and Structure: Nylon Fiber vs Nylon Film

Nylon fiber consists of long, continuous polymer chains arranged in a semi-crystalline structure that provides high tensile strength and elasticity, making it ideal for textile applications. Nylon film, however, is formed by casting or extrusion processes that produce a thin, flexible sheet with a more amorphous structure, offering excellent barrier properties and dimensional stability. Both share the polyamide composition but differ significantly in molecular orientation and crystallinity, influencing their mechanical and chemical performance.

Manufacturing Processes of Nylon Fiber and Film

Nylon fiber manufacturing involves melt spinning, where molten nylon is extruded through spinnerets to form continuous filaments that are subsequently drawn to align molecular chains and enhance strength. Nylon film production utilizes a casting or blown film extrusion process, where nylon resin is melted and either spread onto a chilled roll or inflated into a thin film bubble for cooling and solidification. Both processes employ controlled temperature and cooling rates to optimize the polymer's crystallinity and mechanical properties specific to fiber or film applications.

Mechanical Properties Comparison

Nylon fiber exhibits high tensile strength and excellent abrasion resistance, making it ideal for textile applications where durability and flexibility are crucial. In contrast, nylon film offers superior tear resistance and better barrier properties, providing enhanced mechanical stability for packaging and industrial uses. The distinct molecular orientation in fibers results in greater elongation at break, while films typically show increased modulus and dimensional stability under stress.

Applications in Industry: Fiber vs Film

Nylon fiber is predominantly used in the textile and automotive industries for manufacturing durable fabrics, ropes, and tire cords, benefiting from its high tensile strength and elasticity. Nylon film finds extensive applications in packaging, electrical insulation, and food preservation due to its excellent barrier properties and flexibility. The choice between nylon fiber and nylon film depends on required mechanical properties and functional performance in specific industrial applications.

Durability and Longevity: Key Differences

Nylon fiber exhibits exceptional tensile strength and abrasion resistance, contributing to superior durability in textiles and industrial applications. Nylon film offers enhanced chemical resistance and dimensional stability, which increases its longevity in packaging and protective coatings. The choice between Nylon fiber and Nylon film depends on the specific durability requirements and environmental exposure of the end use.

Flexibility and Strength Analysis

Nylon fiber exhibits superior flexibility due to its elongated polymer chains, allowing it to bend and stretch without breaking, making it ideal for textiles and ropes. In contrast, nylon film, created through a calendaring or casting process, offers enhanced tensile strength and resistance to punctures, suitable for packaging and barrier applications. The molecular orientation in nylon film increases its rigidity, reducing flexibility compared to nylon fiber but significantly improving durability under stress.

Moisture Absorption and Barrier Properties

Nylon fiber exhibits higher moisture absorption rates compared to nylon film due to its porous fibrous structure, making it less effective as a moisture barrier. Nylon film, produced via extrusion processes, offers superior barrier properties against water vapor and gases, ideal for packaging applications requiring moisture resistance. The dense, non-porous morphology of nylon film significantly reduces permeability, enhancing its protective performance over nylon fibers.

Environmental Impact: Fiber vs Film

Nylon fiber production generates significant greenhouse gas emissions and consumes high energy, contributing to environmental concerns, while nylon film manufacturing typically produces less waste and allows for more efficient material use. Nylon fiber's end-of-life impact is heightened by its resistance to biodegradation, causing persistent microplastic pollution, whereas nylon films can be engineered for faster degradation or recyclability in certain applications. Sustainable innovations in nylon films include bio-based alternatives and improved recycling technologies, which are less developed in nylon fiber production, highlighting the environmental advantage of nylon film over fiber.

Cost Efficiency in Production and Use

Nylon fiber production costs are generally lower than nylon film due to simpler manufacturing processes and less energy-intensive extrusion techniques. Nylon fibers provide cost efficiency in textiles and industrial applications through durability and lightweight properties, reducing long-term replacement expenses. In contrast, nylon film entails higher initial costs but offers superior barrier properties and strength, making it cost-effective for packaging and specialty applications where performance outweighs base material costs.

Future Trends in Nylon Fiber and Film Technologies

Emerging advancements in nylon fiber technology emphasize enhanced biodegradability and increased mechanical strength, targeting sustainable textile and industrial applications. Innovations in nylon film focus on developing ultra-thin, high-barrier films for superior packaging performance and reduced environmental impact. Integration of nanotechnology and bio-based materials is set to redefine future nylon fiber and film production, promoting eco-friendly and multifunctional solutions.

Nylon fiber vs Nylon film Infographic

materialdif.com

materialdif.com