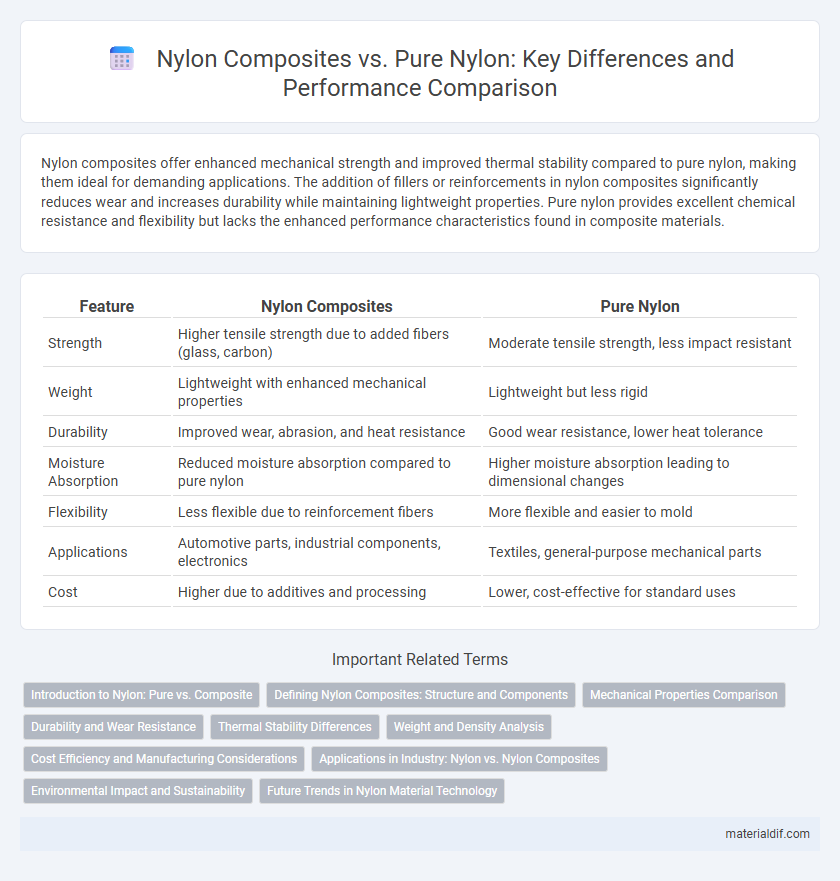

Nylon composites offer enhanced mechanical strength and improved thermal stability compared to pure nylon, making them ideal for demanding applications. The addition of fillers or reinforcements in nylon composites significantly reduces wear and increases durability while maintaining lightweight properties. Pure nylon provides excellent chemical resistance and flexibility but lacks the enhanced performance characteristics found in composite materials.

Table of Comparison

| Feature | Nylon Composites | Pure Nylon |

|---|---|---|

| Strength | Higher tensile strength due to added fibers (glass, carbon) | Moderate tensile strength, less impact resistant |

| Weight | Lightweight with enhanced mechanical properties | Lightweight but less rigid |

| Durability | Improved wear, abrasion, and heat resistance | Good wear resistance, lower heat tolerance |

| Moisture Absorption | Reduced moisture absorption compared to pure nylon | Higher moisture absorption leading to dimensional changes |

| Flexibility | Less flexible due to reinforcement fibers | More flexible and easier to mold |

| Applications | Automotive parts, industrial components, electronics | Textiles, general-purpose mechanical parts |

| Cost | Higher due to additives and processing | Lower, cost-effective for standard uses |

Introduction to Nylon: Pure vs. Composite

Nylon composites combine pure nylon with reinforcing materials such as glass fibers or carbon fibers to enhance mechanical strength, thermal stability, and wear resistance compared to pure nylon. Pure nylon, a synthetic polymer known for its flexibility, durability, and moisture absorption, serves as the base material but lacks the reinforced properties of composites. The choice between pure nylon and nylon composites depends on application-specific requirements for strength, weight, and environmental resistance.

Defining Nylon Composites: Structure and Components

Nylon composites consist of a nylon polymer matrix reinforced with materials such as glass fibers, carbon fibers, or minerals, enhancing mechanical properties like strength, stiffness, and thermal resistance compared to pure nylon. The composite structure allows for tailored performance attributes by varying the type, orientation, and concentration of reinforcement within the nylon base. This combination results in materials that maintain the inherent flexibility and chemical resistance of pure nylon while significantly improving durability and load-bearing capacity for demanding engineering applications.

Mechanical Properties Comparison

Nylon composites exhibit significantly enhanced mechanical properties compared to pure nylon, including higher tensile strength, improved impact resistance, and greater stiffness due to the incorporation of reinforcing fibers such as glass or carbon. The fiber reinforcement in nylon composites reduces material deformation under load and increases durability, making them suitable for demanding engineering applications. Pure nylon, while flexible and wear-resistant, generally offers lower mechanical strength and is more prone to creep under sustained stress than reinforced composites.

Durability and Wear Resistance

Nylon composites exhibit significantly enhanced durability and wear resistance compared to pure nylon, due to the incorporation of reinforcing fibers such as glass or carbon. These composites provide superior mechanical strength, improved impact resistance, and reduced abrasion, making them ideal for high-stress applications. Pure nylon, while flexible and chemically resistant, tends to wear faster under friction and heavy load conditions, limiting its lifespan in demanding environments.

Thermal Stability Differences

Nylon composites exhibit significantly enhanced thermal stability compared to pure nylon, due to the reinforcement materials such as glass fibers or carbon fibers that improve heat resistance and dimensional stability at elevated temperatures. Pure nylon typically begins to degrade or lose mechanical properties around 200degC, while nylon composites can maintain structural integrity and performance above this threshold, often reaching up to 250degC or higher depending on the composite formulation. This thermal stability differential makes nylon composites more suitable for demanding applications in automotive, aerospace, and industrial sectors where heat exposure is critical.

Weight and Density Analysis

Nylon composites exhibit significantly lower weight compared to pure nylon due to the integration of reinforcing materials such as glass or carbon fibers, which enhance strength while reducing bulk density. Pure nylon typically has a density ranging from 1.13 to 1.15 g/cm3, whereas nylon composites can achieve densities as low as 1.0 to 1.2 g/cm3 depending on the fiber content and type. This reduction in weight and optimized density improves the performance of components in automotive and aerospace applications where lightweight materials are crucial.

Cost Efficiency and Manufacturing Considerations

Nylon composites offer enhanced mechanical properties and durability compared to pure nylon, making them more cost-efficient in high-performance applications despite higher initial material costs. Manufacturing considerations include the need for specialized processing techniques such as injection molding with reinforced fibers, which can increase production complexity but result in longer-lasting components. Pure nylon remains preferable for simpler, low-stress parts due to its lower material cost and easier manufacturability.

Applications in Industry: Nylon vs. Nylon Composites

Nylon composites offer enhanced mechanical properties such as increased strength, stiffness, and heat resistance compared to pure nylon, making them ideal for demanding industrial applications like automotive parts, electrical components, and aerospace structures. Pure nylon is preferred in applications requiring flexibility, chemical resistance, and cost-effectiveness, such as textile fibers, packaging, and consumer goods. The choice between nylon composites and pure nylon depends on specific performance requirements, with composites dominating high-stress environments and pure nylon favored for lightweight and corrosion-resistant uses.

Environmental Impact and Sustainability

Nylon composites typically incorporate reinforcing fibers such as glass or carbon, which enhance mechanical strength but complicate recycling compared to pure nylon. Pure nylon demonstrates higher recyclability and a lower environmental footprint due to its simpler polymer structure and fewer additives. Lifecycle assessments reveal that pure nylon offers greater sustainability potential by facilitating circular economy practices and reducing landfill accumulation.

Future Trends in Nylon Material Technology

Nylon composites offer enhanced mechanical strength, thermal stability, and chemical resistance compared to pure nylon, driving their adoption in automotive, aerospace, and industrial applications. Future trends emphasize the development of bio-based nylon composites and advanced nanofillers to improve sustainability and performance metrics, including durability and weight reduction. Innovations in processing techniques, such as additive manufacturing and advanced extrusion, will further optimize the material properties and expand its usability in high-performance, eco-friendly solutions.

Nylon Composites vs Pure Nylon Infographic

materialdif.com

materialdif.com