Nylon 610 offers excellent chemical resistance and low moisture absorption, making it ideal for applications exposed to humid or corrosive environments. Nylon 612 provides superior dimensional stability and lower water uptake compared to Nylon 610, enhancing performance in precision parts and engineering components. Both materials exhibit strong mechanical properties, but Nylon 612's improved moisture resistance often makes it the preferred choice for long-term durability.

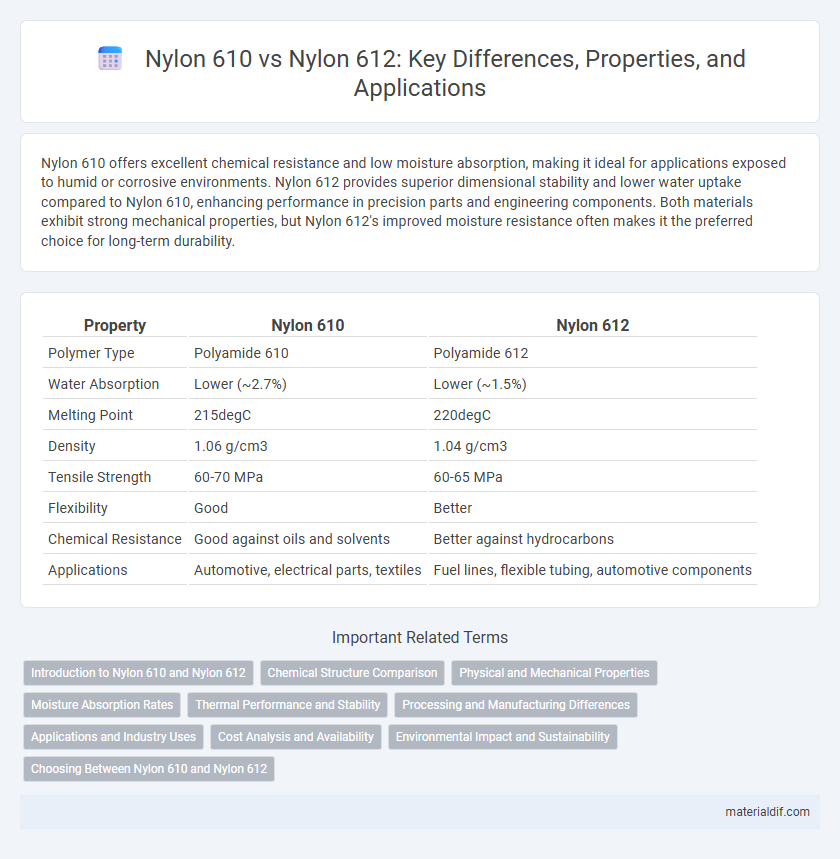

Table of Comparison

| Property | Nylon 610 | Nylon 612 |

|---|---|---|

| Polymer Type | Polyamide 610 | Polyamide 612 |

| Water Absorption | Lower (~2.7%) | Lower (~1.5%) |

| Melting Point | 215degC | 220degC |

| Density | 1.06 g/cm3 | 1.04 g/cm3 |

| Tensile Strength | 60-70 MPa | 60-65 MPa |

| Flexibility | Good | Better |

| Chemical Resistance | Good against oils and solvents | Better against hydrocarbons |

| Applications | Automotive, electrical parts, textiles | Fuel lines, flexible tubing, automotive components |

Introduction to Nylon 610 and Nylon 612

Nylon 610 and Nylon 612 are polyamides known for their excellent chemical resistance, low moisture absorption, and high thermal stability, making them suitable for automotive and industrial applications. Nylon 610 offers a balance of rigidity and flexibility due to its shorter carbon chain length, while Nylon 612 provides enhanced durability and improved dimensional stability because of its longer carbon chain. Both materials exhibit superior fatigue resistance and are ideal for components requiring consistent mechanical performance under varying environmental conditions.

Chemical Structure Comparison

Nylon 610 consists of hexamethylene diamine and sebacic acid, featuring a 6-carbon diamine and a 10-carbon diacid, while Nylon 612 is formed from hexamethylene diamine and dodecanedioic acid, containing a 6-carbon diamine and a 12-carbon diacid. The longer carbon chain in Nylon 612's diacid imparts greater flexibility and lower water absorption compared to Nylon 610. These structural differences influence their mechanical properties and thermal stability in various industrial applications.

Physical and Mechanical Properties

Nylon 610 exhibits higher tensile strength and better abrasion resistance compared to Nylon 612, making it more suitable for applications requiring durability under stress. Nylon 612 offers superior flexibility and lower moisture absorption due to its longer molecular chain, which enhances dimensional stability in humid environments. Both materials feature excellent chemical resistance and thermal stability, but Nylon 610 typically withstands higher impact forces, while Nylon 612 provides improved fatigue resistance.

Moisture Absorption Rates

Nylon 610 exhibits significantly lower moisture absorption rates compared to Nylon 612, making it more suitable for applications requiring dimensional stability in humid environments. With a moisture absorption rate around 2.4% at 24 hours of water immersion, Nylon 610 absorbs less water than Nylon 612, which typically absorbs about 2.8% under similar conditions. This difference impacts mechanical properties, as lower moisture uptake in Nylon 610 helps maintain tensile strength and reduces swelling.

Thermal Performance and Stability

Nylon 610 offers higher thermal stability with a melting point around 215degC, making it suitable for applications requiring sustained heat resistance. Nylon 612 has a slightly lower melting point near 190degC but exhibits better dimensional stability and lower moisture absorption, enhancing its performance in humid environments. Both materials provide good thermal performance, but Nylon 610 is preferred for higher temperature endurance while Nylon 612 excels in maintaining structural integrity under fluctuating conditions.

Processing and Manufacturing Differences

Nylon 610 offers lower moisture absorption and improved dimensional stability compared to Nylon 612 due to its longer carbon chain between amide groups, affecting processing characteristics such as drying time and melt temperature. Nylon 612 requires slightly higher processing temperatures but provides better chemical resistance and reduced warping during manufacturing, making it favorable in precision molding applications. Differences in crystallization rates impact cycle times, with Nylon 610 generally enabling faster cooling and injection molding speeds.

Applications and Industry Uses

Nylon 610 offers enhanced chemical resistance and lower water absorption, making it ideal for automotive fuel lines, electrical connectors, and industrial tubing where durability against harsh environments is critical. Nylon 612 provides superior dimensional stability and mechanical strength, favored in applications such as gears, bearings, and electrical components in aerospace and industrial machinery. Both materials are extensively used in the manufacturing sector, with Nylon 610 preferred for fluid handling systems and Nylon 612 chosen for high-performance mechanical parts.

Cost Analysis and Availability

Nylon 610 generally offers a lower cost compared to Nylon 612 due to its more common raw material sources and simpler production process. Availability of Nylon 610 is higher, with widespread suppliers and shorter lead times, whereas Nylon 612 is less prevalent, often resulting in higher prices and limited stock. The cost differential between Nylon 610 and Nylon 612 can impact project budgets significantly, especially in large-scale manufacturing where material sourcing efficiency is critical.

Environmental Impact and Sustainability

Nylon 610 exhibits a lower environmental impact than Nylon 612 due to its higher biobased content derived from sebacic acid sourced from castor oil, reducing reliance on fossil fuels. Both Nylon 610 and Nylon 612 offer improved sustainability compared to traditional nylons, but Nylon 610's greater renewable carbon content enhances its eco-friendly profile. Lifecycle assessments indicate Nylon 610 achieves better carbon footprint reductions, making it a preferable choice for applications prioritizing sustainability.

Choosing Between Nylon 610 and Nylon 612

Nylon 610 offers superior moisture resistance and dimensional stability, making it ideal for automotive and electrical applications exposed to humidity. Nylon 612 provides enhanced chemical resistance and lower water absorption, which suits industrial components requiring durability against oils and fuels. Selecting between Nylon 610 and Nylon 612 depends on the specific environmental factors and performance demands of the intended use.

Nylon 610 vs Nylon 612 Infographic

materialdif.com

materialdif.com