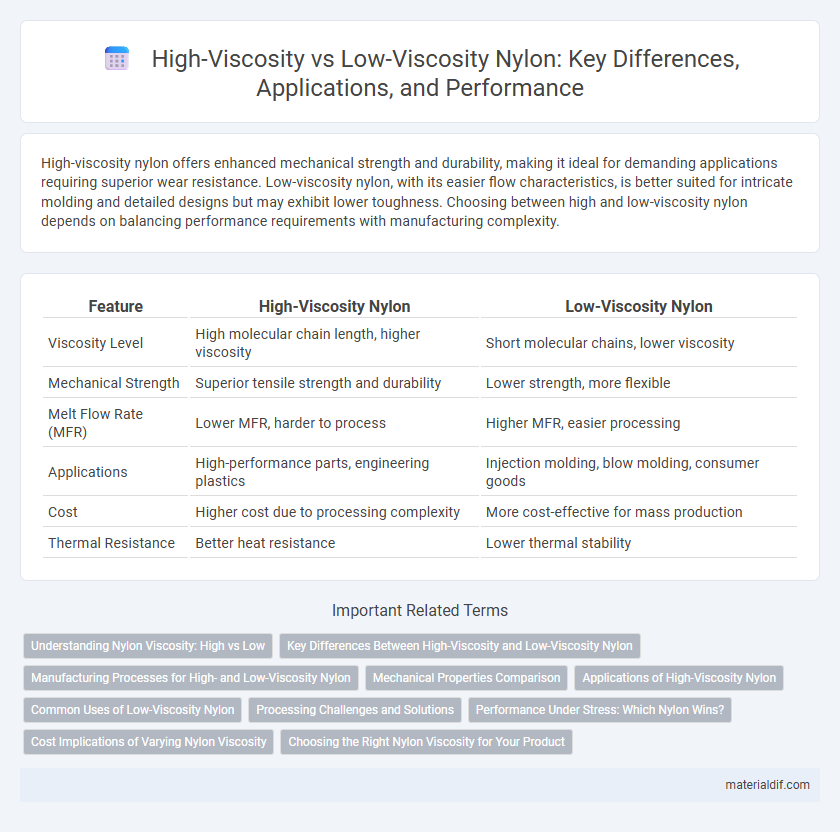

High-viscosity nylon offers enhanced mechanical strength and durability, making it ideal for demanding applications requiring superior wear resistance. Low-viscosity nylon, with its easier flow characteristics, is better suited for intricate molding and detailed designs but may exhibit lower toughness. Choosing between high and low-viscosity nylon depends on balancing performance requirements with manufacturing complexity.

Table of Comparison

| Feature | High-Viscosity Nylon | Low-Viscosity Nylon |

|---|---|---|

| Viscosity Level | High molecular chain length, higher viscosity | Short molecular chains, lower viscosity |

| Mechanical Strength | Superior tensile strength and durability | Lower strength, more flexible |

| Melt Flow Rate (MFR) | Lower MFR, harder to process | Higher MFR, easier processing |

| Applications | High-performance parts, engineering plastics | Injection molding, blow molding, consumer goods |

| Cost | Higher cost due to processing complexity | More cost-effective for mass production |

| Thermal Resistance | Better heat resistance | Lower thermal stability |

Understanding Nylon Viscosity: High vs Low

Nylon viscosity significantly influences its processing and mechanical properties, with high-viscosity nylon exhibiting greater molecular weight and enhanced tensile strength, making it ideal for demanding engineering applications. Low-viscosity nylon, characterized by lower molecular weight, offers better melt flow and easier moldability, suitable for intricate designs and fast processing cycles. Understanding the balance between high and low viscosity nylon allows manufacturers to optimize performance and manufacturing efficiency based on specific application requirements.

Key Differences Between High-Viscosity and Low-Viscosity Nylon

High-viscosity nylon features longer molecular chains, resulting in increased tensile strength, higher melting points, and enhanced wear resistance compared to low-viscosity nylon. Low-viscosity nylon has shorter polymer chains, providing better flow characteristics for intricate molding but lower mechanical properties and impact resistance. These differences make high-viscosity nylon ideal for heavy-duty applications, while low-viscosity nylon suits precision parts requiring complex shapes.

Manufacturing Processes for High- and Low-Viscosity Nylon

High-viscosity nylon, characterized by a higher molecular weight, requires precise temperature and pressure control during polymerization to achieve optimal chain length and mechanical strength, making processes like solution polymerization and solid-state polymerization preferred. Low-viscosity nylon, with shorter polymer chains, is typically produced via melt polymerization, enabling faster reaction rates and easier processing but yielding materials with lower tensile strength. Manufacturing high-viscosity nylon demands extended reaction times and careful heat management to avoid degradation, while low-viscosity nylon production focuses on efficiency and scalability for applications requiring flexibility and ease of molding.

Mechanical Properties Comparison

High-viscosity nylon exhibits superior tensile strength and impact resistance compared to low-viscosity variants, making it ideal for demanding engineering applications. Low-viscosity nylon offers enhanced processability and better flow characteristics but compromises on stiffness and durability. Mechanical properties such as elongation at break and fatigue resistance are significantly higher in high-viscosity nylon, contributing to longer lifespan in high-stress environments.

Applications of High-Viscosity Nylon

High-viscosity nylon, known for its superior mechanical strength and enhanced wear resistance, is widely used in demanding engineering applications such as automotive components, electrical connectors, and industrial gears. Its higher molecular weight provides excellent durability and dimensional stability, making it ideal for parts subject to high stress and friction. These properties set high-viscosity nylon apart from low-viscosity nylon, which is typically used in less mechanically intensive applications like textiles and packaging.

Common Uses of Low-Viscosity Nylon

Low-viscosity nylon is widely used in applications requiring ease of processing and excellent flow characteristics, such as injection molding of complex components like automotive parts, electrical connectors, and consumer goods. Its lower molecular weight allows for faster melting and molding cycles, making it ideal for producing thin-walled and intricately shaped items. The material also finds use in textile fibers, films, and coatings where smooth surface finish and flexibility are essential.

Processing Challenges and Solutions

High-viscosity nylon exhibits superior mechanical strength but presents processing challenges such as increased melt temperature and higher torque requirements, often leading to nozzle clogging and inconsistent flow during injection molding. Low-viscosity nylon offers easier flow and reduced processing temperature, minimizing equipment wear and cycle time, but may compromise on final part toughness and durability. Optimizing processing parameters like temperature control, screw speed, and mold design can mitigate these challenges, ensuring balanced performance and manufacturability for both high- and low-viscosity nylon grades.

Performance Under Stress: Which Nylon Wins?

High-viscosity nylon exhibits superior tensile strength and impact resistance, making it ideal for applications requiring durability under mechanical stress. Low-viscosity nylon offers better flow characteristics during molding but tends to have lower mechanical resilience and fatigue resistance. Under high-stress conditions, high-viscosity nylon consistently outperforms low-viscosity variants, ensuring enhanced performance and longer service life.

Cost Implications of Varying Nylon Viscosity

High-viscosity nylon typically incurs higher production costs due to its increased molecular weight, leading to enhanced strength and durability suitable for demanding applications. Low-viscosity nylon offers cost savings in processing and material usage but may compromise mechanical properties, making it ideal for less intensive uses. Manufacturers must balance performance requirements and budget constraints when selecting nylon viscosity grades.

Choosing the Right Nylon Viscosity for Your Product

High-viscosity nylon offers enhanced mechanical strength and abrasion resistance, making it ideal for applications requiring durability and wear resistance, such as automotive parts and industrial components. Low-viscosity nylon provides better flow characteristics and ease of molding, suitable for complex shapes and detailed injection-molded products in consumer electronics and small precision parts. Selecting the appropriate nylon viscosity depends on balancing product performance requirements with manufacturing capabilities to optimize both functionality and production efficiency.

High-viscosity nylon vs Low-viscosity nylon Infographic

materialdif.com

materialdif.com