Nylon resin offers higher consistency and better mechanical strength compared to nylon powder, making it ideal for injection molding and durable applications. Nylon powder is preferred for additive manufacturing and powder metallurgy due to its fine particle size, allowing precise layering and complex geometries. Choosing between nylon resin and nylon powder depends on the required manufacturing process and the desired material properties for the final product.

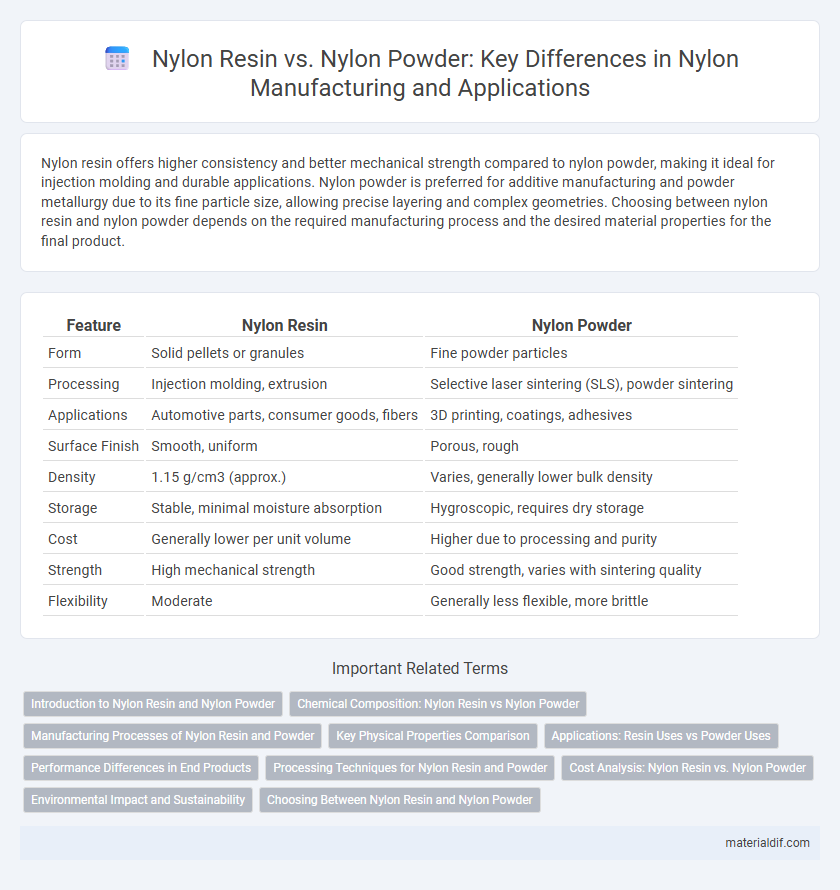

Table of Comparison

| Feature | Nylon Resin | Nylon Powder |

|---|---|---|

| Form | Solid pellets or granules | Fine powder particles |

| Processing | Injection molding, extrusion | Selective laser sintering (SLS), powder sintering |

| Applications | Automotive parts, consumer goods, fibers | 3D printing, coatings, adhesives |

| Surface Finish | Smooth, uniform | Porous, rough |

| Density | 1.15 g/cm3 (approx.) | Varies, generally lower bulk density |

| Storage | Stable, minimal moisture absorption | Hygroscopic, requires dry storage |

| Cost | Generally lower per unit volume | Higher due to processing and purity |

| Strength | High mechanical strength | Good strength, varies with sintering quality |

| Flexibility | Moderate | Generally less flexible, more brittle |

Introduction to Nylon Resin and Nylon Powder

Nylon resin is a thermoplastic material commonly used in injection molding and extrusion processes due to its excellent mechanical strength and chemical resistance. Nylon powder, on the other hand, is a fine particulate form utilized primarily in powder coating, selective laser sintering (SLS) 3D printing, and composite manufacturing for enhanced surface finish and precision. Both forms of nylon exhibit high durability and thermal stability, but the choice between resin and powder depends on specific application requirements such as manufacturing method and desired material properties.

Chemical Composition: Nylon Resin vs Nylon Powder

Nylon resin primarily consists of long polymer chains formed through the condensation of diamines and dicarboxylic acids, resulting in solid, thermoplastic pellets used for molding and extrusion. Nylon powder is finely ground Nylon resin, maintaining the same polyamide chemical structure but offering increased surface area and faster melting behavior during processes like selective laser sintering in additive manufacturing. Both forms share the characteristic amide linkages in their molecular backbone, but their physical state influences processing techniques and application performance.

Manufacturing Processes of Nylon Resin and Powder

Nylon resin is typically produced through a polymerization process involving caprolactam or hexamethylene diamine and adipic acid, followed by extrusion and pelletizing to form solid resin beads used in injection molding. Nylon powder manufacturing commonly employs methods such as spray drying or cryogenic grinding to create fine, uniform particles suitable for powder coating and selective laser sintering in additive manufacturing. Both forms require precise control of temperature and moisture during processing to ensure optimal molecular weight and mechanical properties for end-use applications.

Key Physical Properties Comparison

Nylon resin typically exhibits higher density, superior melting point, and enhanced tensile strength compared to Nylon powder, making it suitable for injection molding and extrusion processes. Nylon powder offers greater surface area and lower particle size, enabling finer sintering in additive manufacturing and improved flow in powder-based formulations. The physical state difference significantly affects moisture absorption rates, with resin generally showing lower water uptake than powder, impacting dimensional stability and mechanical properties.

Applications: Resin Uses vs Powder Uses

Nylon resin is commonly used in injection molding and extrusion processes to produce automotive parts, electrical components, and consumer goods due to its high strength and durability. Nylon powder, favored in selective laser sintering (SLS) 3D printing, enables the creation of complex geometries for prototyping, customized medical devices, and lightweight aerospace components. The choice between nylon resin and nylon powder depends largely on the manufacturing technique and application requirements, with resin suited for mass production and powder ideal for rapid prototyping and intricate designs.

Performance Differences in End Products

Nylon resin offers superior mechanical strength and consistent durability in molded parts compared to nylon powder, which is ideal for additive manufacturing but may result in lower impact resistance. Nylon resin typically provides enhanced thermal stability and moisture resistance, critical for high-performance applications such as automotive components and industrial gears. In contrast, nylon powder allows for more complex geometries in 3D printing but may require post-processing to achieve comparable surface finish and mechanical properties.

Processing Techniques for Nylon Resin and Powder

Nylon resin typically undergoes injection molding and extrusion processes, offering precise control over part dimensions and surface finish due to its melt flow properties. Nylon powder is primarily used in selective laser sintering (SLS) 3D printing and rotational molding, enabling complex geometries and porosity control not achievable with resin. Processing techniques for Nylon powder emphasize layer-by-layer fusion and sintering parameters, while resin processing focuses on thermal melting and shear rates for optimal flow and mechanical strength.

Cost Analysis: Nylon Resin vs. Nylon Powder

Nylon resin generally incurs higher production costs due to its complex extrusion and molding processes, whereas nylon powder offers cost efficiency with lower raw material expenses and simplified processing methods such as powder bed fusion in additive manufacturing. The bulk handling and reduced waste during fabrication of nylon powder contribute to decreased overall operational costs compared to nylon resin, which often requires additional post-processing. Evaluating total cost of ownership reveals nylon powder as a more economical choice in large-scale and flexible manufacturing applications.

Environmental Impact and Sustainability

Nylon resin typically requires more energy-intensive processing and generates higher greenhouse gas emissions compared to nylon powder, which can be produced via low-impact methods like electrostatic coatings or additive manufacturing. Nylon powder enables improved material recyclability and reduces waste through precise, additive fabrication techniques, enhancing overall sustainability. The adoption of nylon powder in industrial applications supports circular economy principles by facilitating closed-loop recycling and minimizing environmental footprint.

Choosing Between Nylon Resin and Nylon Powder

Nylon resin offers superior mechanical strength and is ideal for injection molding applications requiring precise, durable parts. In contrast, nylon powder is preferred for additive manufacturing and sintering techniques, enabling intricate geometries and rapid prototyping. Selecting between nylon resin and nylon powder depends on production method, part complexity, and desired finish quality.

Nylon resin vs Nylon powder Infographic

materialdif.com

materialdif.com