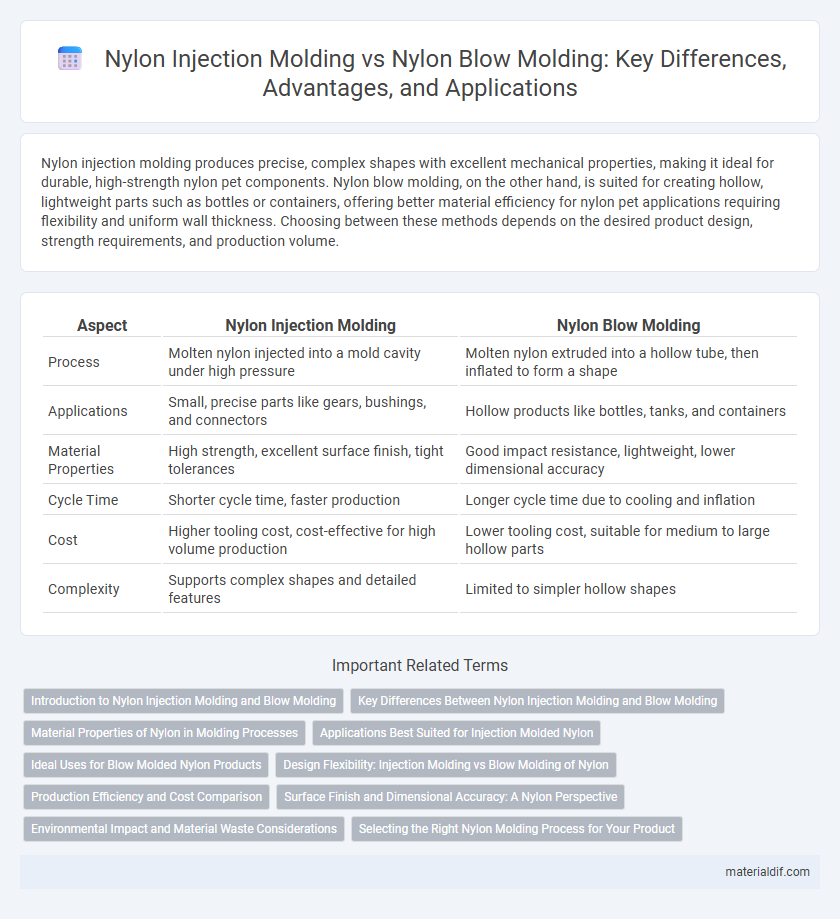

Nylon injection molding produces precise, complex shapes with excellent mechanical properties, making it ideal for durable, high-strength nylon pet components. Nylon blow molding, on the other hand, is suited for creating hollow, lightweight parts such as bottles or containers, offering better material efficiency for nylon pet applications requiring flexibility and uniform wall thickness. Choosing between these methods depends on the desired product design, strength requirements, and production volume.

Table of Comparison

| Aspect | Nylon Injection Molding | Nylon Blow Molding |

|---|---|---|

| Process | Molten nylon injected into a mold cavity under high pressure | Molten nylon extruded into a hollow tube, then inflated to form a shape |

| Applications | Small, precise parts like gears, bushings, and connectors | Hollow products like bottles, tanks, and containers |

| Material Properties | High strength, excellent surface finish, tight tolerances | Good impact resistance, lightweight, lower dimensional accuracy |

| Cycle Time | Shorter cycle time, faster production | Longer cycle time due to cooling and inflation |

| Cost | Higher tooling cost, cost-effective for high volume production | Lower tooling cost, suitable for medium to large hollow parts |

| Complexity | Supports complex shapes and detailed features | Limited to simpler hollow shapes |

Introduction to Nylon Injection Molding and Blow Molding

Nylon injection molding involves injecting molten nylon into a mold cavity under high pressure, producing precise, complex shapes with excellent mechanical properties and surface finish. Blow molding for nylon entails inflating molten nylon inside a mold to form hollow, lightweight parts such as bottles and containers, emphasizing efficient material use and design flexibility. Both processes leverage nylon's high strength, chemical resistance, and thermal stability but cater to different product requirements based on part geometry and function.

Key Differences Between Nylon Injection Molding and Blow Molding

Nylon injection molding involves injecting molten nylon into a rigid mold to produce precise, high-strength components with complex geometries, ideal for small to medium-sized parts requiring tight tolerances. Nylon blow molding, on the other hand, uses compressed air to inflate heated nylon parisons into hollow shapes, making it suitable for producing lightweight, hollow parts like bottles or containers with less dimensional accuracy. The key differences lie in product complexity, structural integrity, and application: injection molding delivers dense, durable parts, while blow molding provides economical solutions for hollow, large-volume nylon products.

Material Properties of Nylon in Molding Processes

Nylon exhibits high crystallinity, excellent abrasion resistance, and strong mechanical properties, which influence its behavior in both injection and blow molding processes. In injection molding, Nylon's viscosity and thermal stability enable precise, complex shapes with minimal warping, while blow molding leverages Nylon's flexibility and toughness to create hollow, lightweight structures. Moisture absorption is a critical factor for Nylon, affecting dimensional stability and requiring careful drying before molding to maintain optimal material performance.

Applications Best Suited for Injection Molded Nylon

Injection molded nylon excels in producing complex, high-strength components such as automotive gears, electrical housings, and industrial machinery parts due to its precise dimensional control and superior mechanical properties. This process is best suited for applications requiring intricate designs, tight tolerances, and enhanced durability, including connectors, fasteners, and consumer electronics. Compared to blow molding, injection molding offers better structural integrity and surface finish, making it ideal for functional, load-bearing components.

Ideal Uses for Blow Molded Nylon Products

Blow molded nylon products excel in creating hollow, lightweight containers such as fuel tanks, reservoirs, and intricate automotive components requiring chemical resistance and durability. The blow molding process allows for uniform wall thickness and complex shapes that are difficult to achieve with injection molding, making it ideal for applications where airtight and liquid-tight performance is critical. Nylon's inherent strength and thermal stability further enhance the suitability of blow molded parts in harsh environments and high-stress mechanical applications.

Design Flexibility: Injection Molding vs Blow Molding of Nylon

Nylon injection molding offers superior design flexibility with intricate geometries, tight tolerances, and complex features, making it ideal for detailed, high-precision parts. Blow molding of nylon is limited in design complexity, primarily suited for hollow objects with uniform wall thickness and simpler shapes. The choice between injection and blow molding depends on the required part complexity, with injection molding enabling more sophisticated nylon component designs.

Production Efficiency and Cost Comparison

Nylon injection molding offers higher production efficiency with faster cycle times and precise control over complex geometries, making it ideal for high-volume, detailed parts. Nylon blow molding is generally more cost-effective for producing hollow, lightweight components but has slower production rates and less dimensional accuracy compared to injection molding. The choice between nylon injection and blow molding depends on part complexity, production volume, and budget constraints.

Surface Finish and Dimensional Accuracy: A Nylon Perspective

Nylon injection molding offers superior surface finish with smoother, more consistent textures due to precise cavity filling under high pressure, making it ideal for applications requiring fine detail and minimal post-processing. In contrast, Nylon blow molding often results in a slightly rougher surface and less dimensional accuracy because the process relies on air pressure to shape the molten polymer inside a mold, which can lead to variations in wall thickness and contour precision. For critical Nylon components demanding high dimensional fidelity and polished appearance, injection molding remains the preferred manufacturing method.

Environmental Impact and Material Waste Considerations

Nylon injection molding produces less material waste due to precise control over melt flow and minimal scrap generation, making it more efficient for complex, high-precision parts. Nylon blow molding tends to generate more waste from trimming excess material and scrap from the parison, contributing to a higher environmental footprint. Both processes can benefit from recycling nylon scraps, but injection molding generally offers better sustainability through lower raw material consumption and reduced energy use per part.

Selecting the Right Nylon Molding Process for Your Product

Nylon injection molding offers precise dimensional control and high tensile strength, making it ideal for complex, high-strength components such as gears and automotive parts. Nylon blow molding is best suited for hollow, lightweight products like fuel tanks and fluid reservoirs, providing excellent chemical resistance and flexibility. Choosing the right molding process depends on your product's structural demands, production volume, and design complexity to optimize performance and cost-efficiency.

Nylon injection molding vs Nylon blow molding Infographic

materialdif.com

materialdif.com