High tenacity nylon offers superior strength and durability compared to standard nylon, making it ideal for demanding applications requiring enhanced resistance to abrasion and wear. Its molecular structure is engineered for increased tensile strength, which translates to longer-lasting performance in products such as ropes, cables, and industrial textiles. Choosing high tenacity nylon ensures better reliability and safety in environments where material failure is not an option.

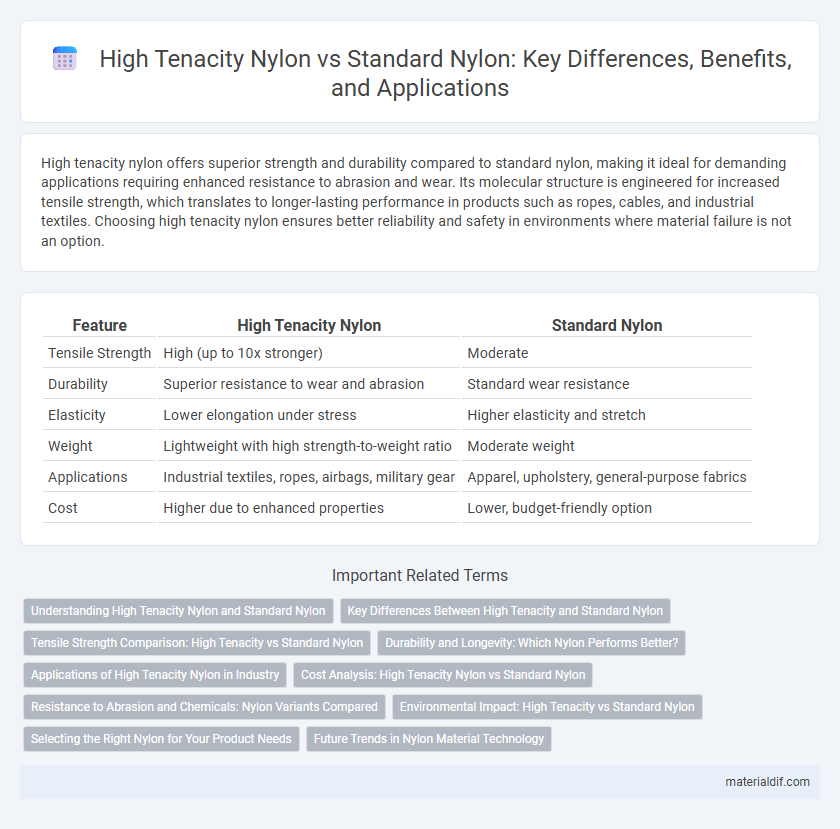

Table of Comparison

| Feature | High Tenacity Nylon | Standard Nylon |

|---|---|---|

| Tensile Strength | High (up to 10x stronger) | Moderate |

| Durability | Superior resistance to wear and abrasion | Standard wear resistance |

| Elasticity | Lower elongation under stress | Higher elasticity and stretch |

| Weight | Lightweight with high strength-to-weight ratio | Moderate weight |

| Applications | Industrial textiles, ropes, airbags, military gear | Apparel, upholstery, general-purpose fabrics |

| Cost | Higher due to enhanced properties | Lower, budget-friendly option |

Understanding High Tenacity Nylon and Standard Nylon

High tenacity nylon offers superior strength and durability compared to standard nylon, making it ideal for demanding applications such as industrial textiles, ropes, and protective gear. This type of nylon has a higher tensile strength due to enhanced polymer chain alignment and increased molecular weight, resulting in improved resistance to wear, abrasion, and impact. Standard nylon provides good versatility and flexibility for everyday uses but lacks the reinforced properties found in high tenacity variants, limiting its performance under extreme stress conditions.

Key Differences Between High Tenacity and Standard Nylon

High tenacity nylon features a higher tensile strength, offering superior durability and resistance to wear compared to standard nylon, which makes it ideal for heavy-duty applications like industrial textiles and automotive parts. Standard nylon provides more flexibility and is generally softer, suited for everyday use in garments and consumer goods where comfort is prioritized. The molecular structure of high tenacity nylon is more tightly aligned, resulting in enhanced mechanical properties and longer lifespan under stress.

Tensile Strength Comparison: High Tenacity vs Standard Nylon

High tenacity nylon exhibits significantly greater tensile strength compared to standard nylon, often measuring up to 20-30% higher in breaking force. This increased durability is achieved through advanced polymer processing techniques that align molecular chains more efficiently. As a result, high tenacity nylon is preferred in applications requiring superior resistance to stress and long-term mechanical performance.

Durability and Longevity: Which Nylon Performs Better?

High tenacity nylon offers superior durability and enhanced resistance to abrasion compared to standard nylon, making it more suitable for applications requiring long-lasting performance. Its molecular structure is engineered to increase tensile strength, resulting in longer lifespan under rigorous conditions. Standard nylon, while versatile and cost-effective, tends to wear out faster and is less resilient to repeated stress and environmental factors.

Applications of High Tenacity Nylon in Industry

High tenacity nylon offers superior strength and durability compared to standard nylon, making it ideal for demanding industrial applications such as automotive components, conveyor belts, and high-performance textiles. Its enhanced tensile strength and abrasion resistance support heavy-duty uses in military gear, safety harnesses, and industrial filtration systems. The material's ability to withstand extreme stress and harsh environmental conditions distinguishes it as a preferred choice in manufacturing and engineering sectors.

Cost Analysis: High Tenacity Nylon vs Standard Nylon

High tenacity nylon offers enhanced strength and durability but comes at a higher production cost compared to standard nylon, impacting overall material expenses. The increased tensile strength of high tenacity nylon reduces maintenance and replacement costs in long-term applications, potentially offsetting the initial price difference. Manufacturers must weigh upfront material investment against lifecycle savings when selecting between high tenacity and standard nylon.

Resistance to Abrasion and Chemicals: Nylon Variants Compared

High tenacity nylon offers superior resistance to abrasion compared to standard nylon, making it ideal for applications requiring enhanced durability under friction and wear. This variant also demonstrates improved chemical resistance, withstanding exposure to oils, solvents, and alkalis better than its standard counterpart. These properties make high tenacity nylon the preferred choice for demanding industrial and outdoor environments.

Environmental Impact: High Tenacity vs Standard Nylon

High tenacity nylon offers enhanced durability and strength, resulting in longer product lifespans and reduced material consumption compared to standard nylon. Standard nylon typically requires more frequent replacement due to lower tensile strength, potentially increasing environmental waste and resource usage. By minimizing the need for frequent recycling or disposal, high tenacity nylon contributes to lower carbon emissions and less environmental strain throughout its lifecycle.

Selecting the Right Nylon for Your Product Needs

High tenacity nylon offers superior tensile strength and abrasion resistance compared to standard nylon, making it ideal for demanding applications such as industrial belts, outdoor gear, and heavy-duty fabrics. Standard nylon provides flexibility and cost-effectiveness for general-purpose uses like apparel, upholstery, and everyday accessories. Selecting the right nylon depends on your product's durability requirements, environmental exposure, and budget constraints to ensure optimal performance and longevity.

Future Trends in Nylon Material Technology

High tenacity nylon offers superior tensile strength and durability compared to standard nylon, making it essential for advanced industrial applications and high-performance textiles. Future trends in nylon material technology emphasize enhanced fiber engineering, sustainable bio-based alternatives, and improved recyclability to meet increasing environmental regulations. Innovations in nanotechnology and polymer blending are expected to further optimize the mechanical properties and functionality of high tenacity nylon, driving its adoption in aerospace, automotive, and smart textile markets.

High tenacity nylon vs Standard nylon Infographic

materialdif.com

materialdif.com