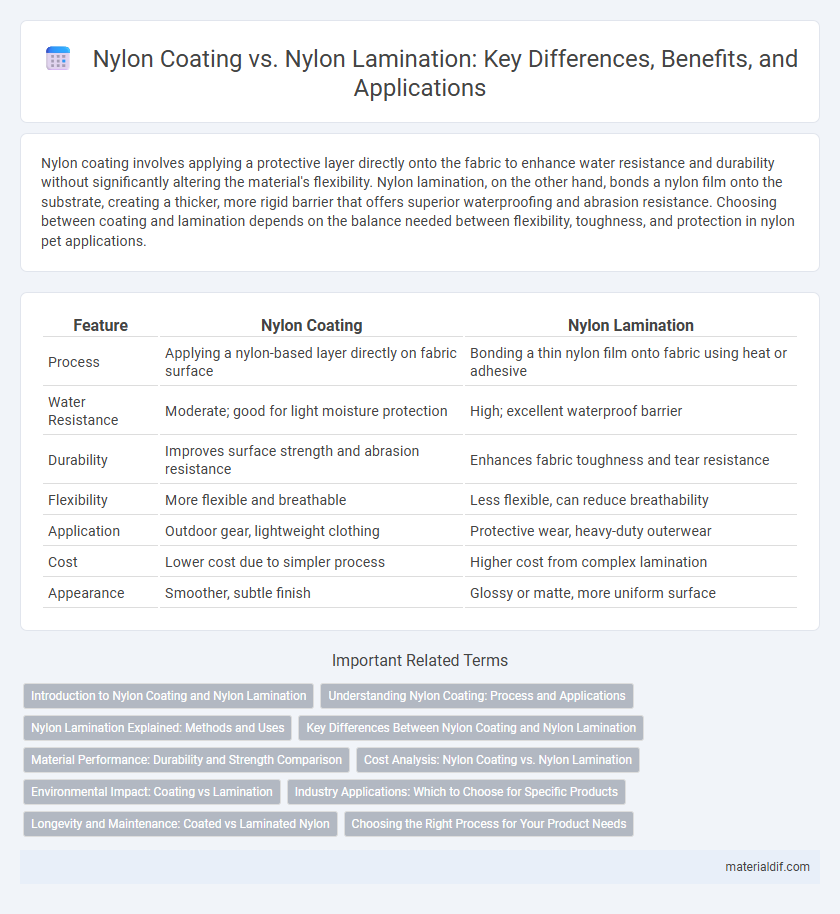

Nylon coating involves applying a protective layer directly onto the fabric to enhance water resistance and durability without significantly altering the material's flexibility. Nylon lamination, on the other hand, bonds a nylon film onto the substrate, creating a thicker, more rigid barrier that offers superior waterproofing and abrasion resistance. Choosing between coating and lamination depends on the balance needed between flexibility, toughness, and protection in nylon pet applications.

Table of Comparison

| Feature | Nylon Coating | Nylon Lamination |

|---|---|---|

| Process | Applying a nylon-based layer directly on fabric surface | Bonding a thin nylon film onto fabric using heat or adhesive |

| Water Resistance | Moderate; good for light moisture protection | High; excellent waterproof barrier |

| Durability | Improves surface strength and abrasion resistance | Enhances fabric toughness and tear resistance |

| Flexibility | More flexible and breathable | Less flexible, can reduce breathability |

| Application | Outdoor gear, lightweight clothing | Protective wear, heavy-duty outerwear |

| Cost | Lower cost due to simpler process | Higher cost from complex lamination |

| Appearance | Smoother, subtle finish | Glossy or matte, more uniform surface |

Introduction to Nylon Coating and Nylon Lamination

Nylon coating involves applying a protective polymer layer directly onto fabric, enhancing water resistance, durability, and abrasion protection without significantly altering the material's flexibility. Nylon lamination, by contrast, bonds a thin layer or film of nylon onto the fabric surface using heat or adhesives, creating a stronger barrier against moisture and improving structural integrity. Both processes optimize the performance of nylon textiles but differ in texture, breathability, and application methods tailored for specific industrial and consumer products.

Understanding Nylon Coating: Process and Applications

Nylon coating involves applying a thin, protective layer of liquid nylon polymer onto fabrics or materials, enhancing durability, water resistance, and abrasion protection without significantly altering flexibility or breathability. This process uses techniques such as dip coating or spray coating to create a uniform, adherent surface ideal for outdoor gear, technical textiles, and industrial applications. Understanding nylon coating helps optimize performance characteristics tailored to specific uses, contrasting with nylon lamination, which bonds a nylon film to substrates for added strength and barrier properties.

Nylon Lamination Explained: Methods and Uses

Nylon lamination involves bonding a thin nylon film to fabrics or substrates using heat and pressure to enhance durability, water resistance, and flexibility. Common methods include solvent-based lamination, hot melt lamination, and extrusion lamination, each offering specific adhesion strengths and performance benefits. This technique is widely used in outdoor gear, protective clothing, and industrial applications where enhanced strength and weather resistance are crucial.

Key Differences Between Nylon Coating and Nylon Lamination

Nylon coating involves applying a liquid polymer directly to a fabric surface, enhancing water resistance, flexibility, and abrasion protection while maintaining breathability. Nylon lamination bonds a thin nylon film layer to the substrate, offering superior waterproofing and durability but often reducing fabric softness and breathability. Key differences include the coating's flexibility and texture retention versus lamination's stronger barrier performance and rigidity.

Material Performance: Durability and Strength Comparison

Nylon coating enhances fabric durability by providing a protective layer that resists abrasion, moisture, and chemicals, making it ideal for outdoor gear and industrial applications. Nylon lamination bonds a thin nylon film to the substrate, significantly increasing tensile strength, water resistance, and tear resistance while maintaining flexibility and lightweight properties. Comparing the two, nylon lamination offers superior strength and waterproof capability, whereas nylon coating excels in abrasion resistance and fabric breathability.

Cost Analysis: Nylon Coating vs. Nylon Lamination

Nylon coating typically involves applying a liquid or powder layer directly onto the fabric, resulting in a lower-cost process with faster production times compared to nylon lamination, which fuses a nylon film onto the substrate, incurring higher material and equipment expenses. The initial investment and operational costs for nylon lamination are significantly greater due to the complexity of heat and pressure requirements, whereas nylon coating offers cost-effective scalability for large-volume applications. Despite higher upfront expenses, nylon lamination provides superior durability and water resistance, which can justify the increased cost in premium or performance-focused products.

Environmental Impact: Coating vs Lamination

Nylon coating typically involves applying a liquid polymer layer that can release volatile organic compounds (VOCs) during production, contributing to environmental pollution. Nylon lamination uses heat and adhesive films, often resulting in less chemical waste and lower emissions, making it a more eco-friendly option. Both methods impact durability and recyclability, but lamination generally offers improved sustainability due to reduced toxic residue and easier material recovery.

Industry Applications: Which to Choose for Specific Products

Nylon coating offers superior abrasion resistance and water repellency ideal for outdoor gear, automotive parts, and industrial textiles requiring durability under harsh conditions. Nylon lamination provides enhanced flexibility and improved barrier properties suitable for medical packaging, food wrapping, and protective clothing where breathability and moisture control are crucial. Selecting between nylon coating and lamination depends on the product's need for toughness versus flexibility and permeability, influencing performance in targeted industry applications.

Longevity and Maintenance: Coated vs Laminated Nylon

Nylon coating enhances fabric durability by adding a protective layer that resists abrasion, moisture, and dirt, making it easier to clean and maintain over time. Nylon lamination, on the other hand, involves bonding a thin film directly to the fabric, increasing water resistance and structural strength but requiring more careful handling to avoid delamination and damage. Coated nylon generally offers superior longevity with simpler maintenance, while laminated nylon provides enhanced barrier properties at the cost of increased sensitivity to wear.

Choosing the Right Process for Your Product Needs

Nylon coating involves applying a protective layer directly onto the fabric surface, enhancing water resistance and durability without altering the fabric's flexibility, making it ideal for lightweight applications like apparel. Nylon lamination, by bonding a thin film to the base fabric, offers superior waterproofing and wind resistance, perfectly suited for outdoor gear and industrial uses. Selecting between nylon coating and nylon lamination depends on specific product requirements such as breathability, flexibility, and environmental exposure, ensuring optimal performance and longevity.

Nylon Coating vs Nylon Lamination Infographic

materialdif.com

materialdif.com