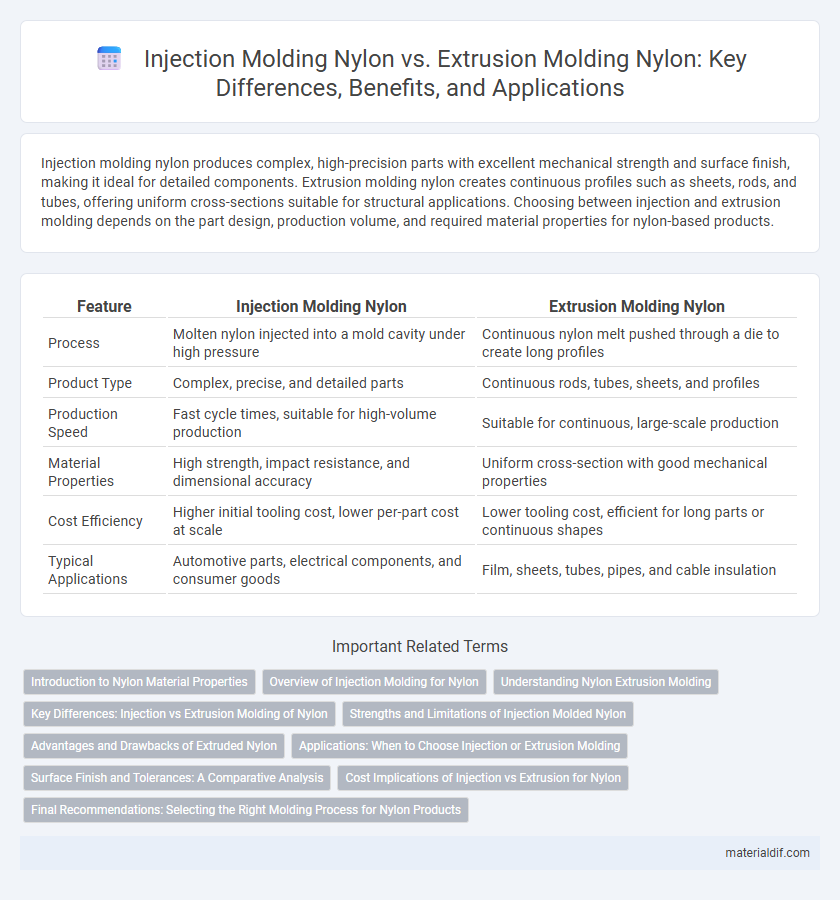

Injection molding nylon produces complex, high-precision parts with excellent mechanical strength and surface finish, making it ideal for detailed components. Extrusion molding nylon creates continuous profiles such as sheets, rods, and tubes, offering uniform cross-sections suitable for structural applications. Choosing between injection and extrusion molding depends on the part design, production volume, and required material properties for nylon-based products.

Table of Comparison

| Feature | Injection Molding Nylon | Extrusion Molding Nylon |

|---|---|---|

| Process | Molten nylon injected into a mold cavity under high pressure | Continuous nylon melt pushed through a die to create long profiles |

| Product Type | Complex, precise, and detailed parts | Continuous rods, tubes, sheets, and profiles |

| Production Speed | Fast cycle times, suitable for high-volume production | Suitable for continuous, large-scale production |

| Material Properties | High strength, impact resistance, and dimensional accuracy | Uniform cross-section with good mechanical properties |

| Cost Efficiency | Higher initial tooling cost, lower per-part cost at scale | Lower tooling cost, efficient for long parts or continuous shapes |

| Typical Applications | Automotive parts, electrical components, and consumer goods | Film, sheets, tubes, pipes, and cable insulation |

Introduction to Nylon Material Properties

Nylon, a versatile thermoplastic known for its high tensile strength, excellent abrasion resistance, and chemical stability, is widely used in both injection molding and extrusion molding processes. Injection molding of nylon allows for precise, complex geometries and tight tolerances, leveraging nylon's quick cooling and solidification properties. Extrusion molding of nylon produces continuous profiles and tubing, maximizing its elasticity and durability for applications requiring consistent cross-sections and flexibility.

Overview of Injection Molding for Nylon

Injection molding for nylon involves melting nylon pellets and injecting them into a mold cavity under high pressure to create precise, intricate shapes with consistent mechanical properties. This process enables complex geometries and high production rates, making it ideal for manufacturing durable nylon components used in automotive, consumer electronics, and industrial applications. Control over temperature and cooling rates ensures optimal crystallinity and strength in the final molded nylon part.

Understanding Nylon Extrusion Molding

Nylon extrusion molding involves forcing molten nylon through a shaped die to create continuous profiles such as tubes, sheets, or rods, enabling precise control over cross-sectional shapes and consistent material properties. This process is ideal for producing long, uniform components with excellent surface finish and enhanced mechanical strength due to molecular orientation during cooling. Unlike injection molding, which forms complex, discrete parts, extrusion molding of nylon excels in applications requiring extended lengths and consistent dimensions.

Key Differences: Injection vs Extrusion Molding of Nylon

Injection molding of nylon enables the production of complex, high-precision parts by injecting molten nylon into intricate molds under high pressure. Extrusion molding continuously pushes molten nylon through a shaped die to create uniform, long profiles like tubes or sheets, emphasizing volume and consistency. Key differences lie in shape complexity, production speed, and mold design, with injection molding suited for detailed, three-dimensional components and extrusion ideal for continuous, uniform profiles.

Strengths and Limitations of Injection Molded Nylon

Injection molded nylon offers high precision and complex geometries, making it ideal for intricate components with excellent dimensional stability. Its strengths include superior mechanical properties, such as high tensile strength and impact resistance, while limitations involve higher tooling costs and longer cycle times compared to extrusion molding. Injection molding also provides enhanced surface finish and allows for the incorporation of additives like glass fibers to further improve strength and durability.

Advantages and Drawbacks of Extruded Nylon

Extrusion molding of nylon offers continuous production capabilities with consistent cross-sectional profiles, making it cost-effective for long runs of uniform shapes. However, extruded nylon parts often have limited geometric complexity compared to injection molding, and control over dimensional tolerance can be less precise. The process typically results in lower mechanical strength and surface finish quality than injection-molded counterparts, restricting its use in highly detailed or load-bearing applications.

Applications: When to Choose Injection or Extrusion Molding

Injection molding nylon is ideal for producing complex, high-precision components like gears, automotive parts, and electrical housings requiring tight tolerances and intricate shapes. Extrusion molding nylon suits continuous profiles such as tubing, rods, and sheets used in packaging, automotive seals, and industrial applications demanding uniform cross-sections. Selecting injection molding is optimal for mass production of detailed parts, while extrusion molding excels in creating long, consistent shapes with less geometric complexity.

Surface Finish and Tolerances: A Comparative Analysis

Injection molding nylon offers superior surface finish with high detail accuracy and smooth, glossy textures ideal for intricate parts, while extrusion molding nylon typically produces consistent but rougher surfaces with less fine detail. Injection molding provides tighter dimensional tolerances, often within +-0.005 inches, making it suitable for precision components, whereas extrusion molding tolerances are broader, usually around +-0.02 inches, favoring simpler geometries. This distinction impacts the choice of molding process depending on the application's aesthetic and dimensional requirements.

Cost Implications of Injection vs Extrusion for Nylon

Injection molding nylon typically incurs higher upfront tooling costs compared to extrusion molding due to complex mold fabrication and precision requirements. Extrusion molding offers lower initial expenses and is cost-effective for continuous, uniform profiles, making it ideal for high-volume production with simpler shapes. The choice between injection and extrusion molding for nylon hinges on balancing these upfront costs against the desired product complexity and production volume.

Final Recommendations: Selecting the Right Molding Process for Nylon Products

Injection molding nylon offers superior precision and complex geometries, making it ideal for high-strength, detailed components like gears and automotive parts. Extrusion molding nylon is more cost-effective for producing continuous profiles such as tubing and sheets with consistent cross-sections. Choose injection molding for intricate, high-performance applications and extrusion molding for simpler, uniform shapes requiring volume efficiency.

Injection Molding Nylon vs Extrusion Molding Nylon Infographic

materialdif.com

materialdif.com