Nylon pellets offer consistent size and purity, making them ideal for precise processing in injection molding and extrusion. Nylon chips are often irregular in shape and may contain impurities, which can affect the final product's mechanical properties. Choosing nylon pellets over chips ensures better flowability, uniform melting, and enhanced strength in finished products.

Table of Comparison

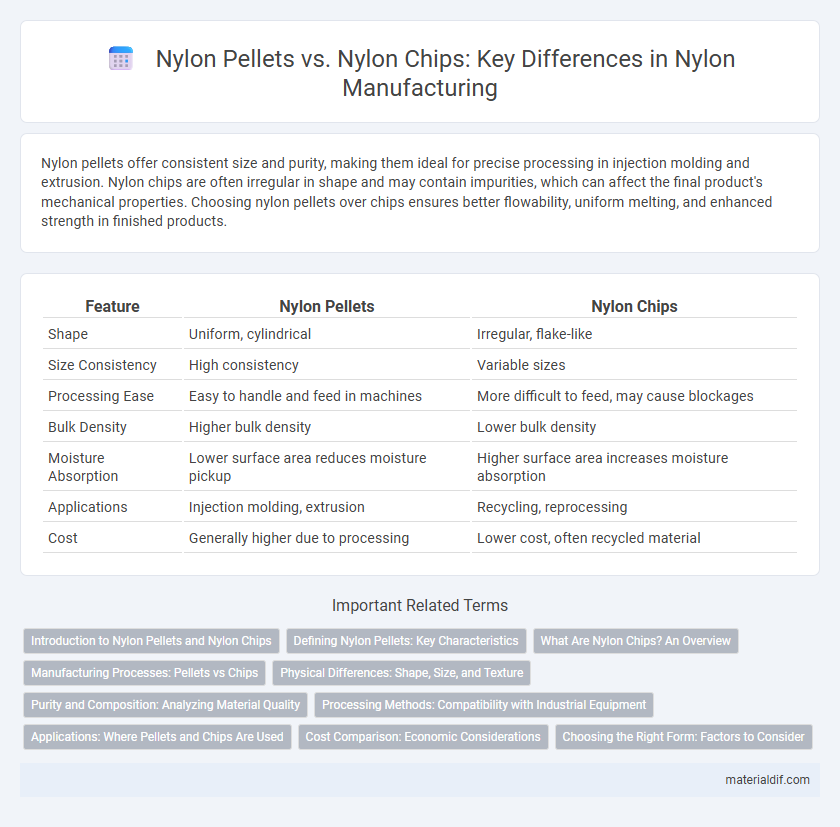

| Feature | Nylon Pellets | Nylon Chips |

|---|---|---|

| Shape | Uniform, cylindrical | Irregular, flake-like |

| Size Consistency | High consistency | Variable sizes |

| Processing Ease | Easy to handle and feed in machines | More difficult to feed, may cause blockages |

| Bulk Density | Higher bulk density | Lower bulk density |

| Moisture Absorption | Lower surface area reduces moisture pickup | Higher surface area increases moisture absorption |

| Applications | Injection molding, extrusion | Recycling, reprocessing |

| Cost | Generally higher due to processing | Lower cost, often recycled material |

Introduction to Nylon Pellets and Nylon Chips

Nylon pellets are small, uniform, cylindrical granules widely used as raw material in injection molding and extrusion processes due to their consistent size and ease of handling. Nylon chips refer to irregularly shaped, coarse fragments often generated during industrial recycling or mechanical processing, typically requiring further refinement before reuse. Understanding the distinction between nylon pellets and chips is crucial for optimizing material flow, melting behavior, and end-product quality in nylon manufacturing.

Defining Nylon Pellets: Key Characteristics

Nylon pellets are small, uniformly shaped granules used as raw material in injection molding and extrusion processes, prized for their consistent size and high purity. Their controlled shape enables precise melting behavior, ensuring uniform flow and minimizing defects in the final product. Unlike irregularly shaped nylon chips, pellets offer enhanced processing efficiency and superior mechanical properties in molded nylon components.

What Are Nylon Chips? An Overview

Nylon chips are small, irregularly shaped fragments created during the production or recycling of nylon materials, serving as a raw intermediate form prior to melting and molding processes. In contrast, nylon pellets are uniformly sized, cylindrical granules engineered for consistent melting behavior and ease of automated handling in polymer processing. Understanding the distinction between nylon chips and pellets is critical for optimizing manufacturing efficiency and material properties in applications such as injection molding, extrusion, and fiber production.

Manufacturing Processes: Pellets vs Chips

Nylon pellets are uniform, small granules produced through controlled polymerization and extrusion processes, facilitating consistent melting and molding in manufacturing. Nylon chips, often irregularly shaped fragments from polymer scrap or recycled materials, require additional processing like drying and homogenizing to ensure quality in re-melting operations. The standardized size and shape of nylon pellets offer enhanced flowability and predictable thermal properties, optimizing injection molding and extrusion efficiency compared to the variable nature of nylon chips.

Physical Differences: Shape, Size, and Texture

Nylon pellets are typically small, uniformly cylindrical or spherical granules designed for consistent melting and easy flow in injection molding processes, while nylon chips are irregular, flat, and larger flakes usually produced as a byproduct from recycling or grinding. The size of nylon pellets ranges from 2 to 5 millimeters in diameter, providing smooth texture and predictable behavior during melting, whereas nylon chips vary widely in size and have rough, uneven surfaces that can affect melt quality. These physical differences in shape, size, and texture influence processing efficiency, with pellets favored for uniformity and chips often requiring additional processing to achieve similar results.

Purity and Composition: Analyzing Material Quality

Nylon pellets exhibit higher purity and more consistent composition compared to nylon chips, which often contain impurities and variable material blends due to the recycling process. The controlled manufacturing of pellets ensures uniform polymer chains, enhancing mechanical properties and processing stability. In contrast, nylon chips may require additional purification steps to achieve comparable quality for high-performance applications.

Processing Methods: Compatibility with Industrial Equipment

Nylon pellets offer superior compatibility with injection molding and extrusion equipment due to their uniform size and consistent melting characteristics, enabling efficient and predictable processing. Nylon chips, while less uniform, are often utilized in recycling processes and require additional processing such as melting or pelletizing to ensure smooth operation in standard industrial machinery. The choice between pellets and chips impacts equipment settings, cycle times, and product quality in manufacturing applications.

Applications: Where Pellets and Chips Are Used

Nylon pellets are predominantly used in injection molding due to their uniform size and ease of melting, making them ideal for producing complex automotive and electrical components. Nylon chips are primarily found in extrusion processes, where their irregular shape facilitates continuous feeding for manufacturing films, fibers, and sheets. Both forms contribute to different manufacturing sectors, optimizing production efficiency and product performance according to application requirements.

Cost Comparison: Economic Considerations

Nylon pellets generally present a more cost-effective option than nylon chips due to their uniform size, which enhances processing efficiency and reduces material waste in manufacturing. The consistent shape and size of pellets facilitate automated handling and melting, leading to lower production downtime and energy consumption compared to the irregular form of nylon chips. Bulk purchasing of nylon pellets often results in volume discounts, further improving the overall economic advantage in large-scale industrial applications.

Choosing the Right Form: Factors to Consider

Nylon pellets offer superior flow and consistent melting characteristics essential for precision injection molding, while nylon chips provide cost-effective bulk processing suitable for extrusion and compounding. Consider factors like processing method, melting uniformity, and end-product quality when choosing between nylon pellets and chips to optimize manufacturing efficiency. Material consistency, thermal stability, and resin handling logistics are critical determinants in selecting the appropriate nylon form for your specific application.

Nylon pellets vs Nylon chips Infographic

materialdif.com

materialdif.com