Nylon rods offer superior durability and are ideal for applications requiring round or cylindrical shapes, such as shafts and bushings. Nylon sheets provide versatility in thickness and machining options, making them suitable for flat components and structural parts. Choosing between nylon rods and sheets depends on the specific project needs, with rods excelling in strength and sheets in custom shaping.

Table of Comparison

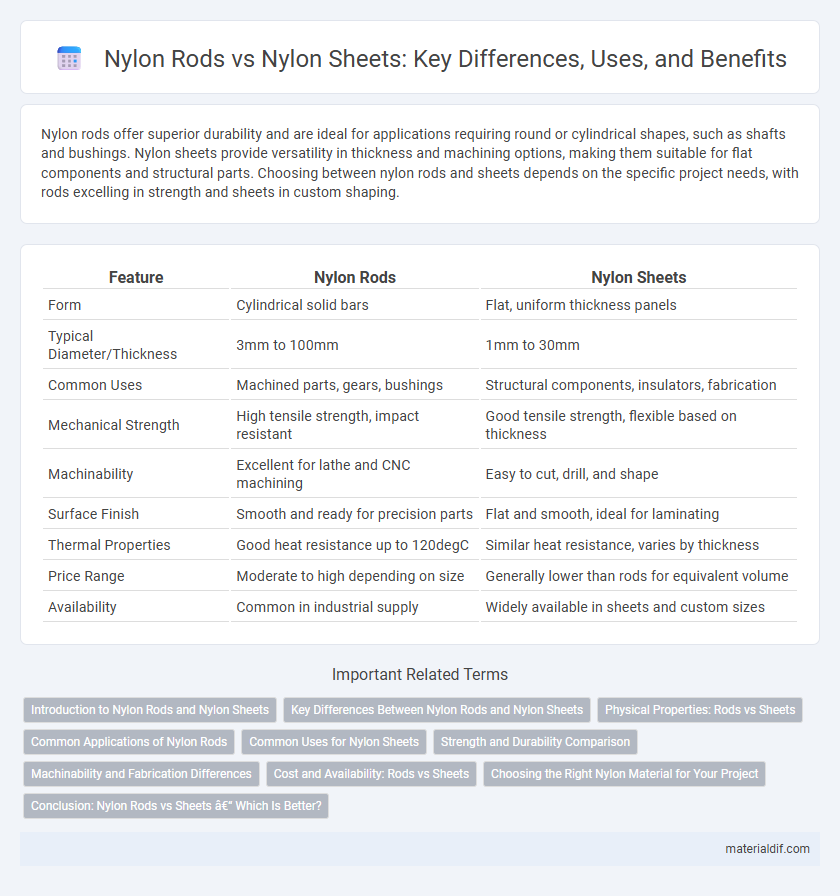

| Feature | Nylon Rods | Nylon Sheets |

|---|---|---|

| Form | Cylindrical solid bars | Flat, uniform thickness panels |

| Typical Diameter/Thickness | 3mm to 100mm | 1mm to 30mm |

| Common Uses | Machined parts, gears, bushings | Structural components, insulators, fabrication |

| Mechanical Strength | High tensile strength, impact resistant | Good tensile strength, flexible based on thickness |

| Machinability | Excellent for lathe and CNC machining | Easy to cut, drill, and shape |

| Surface Finish | Smooth and ready for precision parts | Flat and smooth, ideal for laminating |

| Thermal Properties | Good heat resistance up to 120degC | Similar heat resistance, varies by thickness |

| Price Range | Moderate to high depending on size | Generally lower than rods for equivalent volume |

| Availability | Common in industrial supply | Widely available in sheets and custom sizes |

Introduction to Nylon Rods and Nylon Sheets

Nylon rods and nylon sheets are widely used engineering materials valued for their high strength, chemical resistance, and excellent machinability. Nylon rods typically offer cylindrical shapes ideal for precision components such as gears, bushings, and rollers, while nylon sheets provide flat, uniform surfaces suitable for fabrication into wear pads, structural parts, and custom-cut profiles. Both forms maintain nylon's inherent durability and low friction properties, making them versatile choices across industrial applications.

Key Differences Between Nylon Rods and Nylon Sheets

Nylon rods offer cylindrical shapes ideal for machining into custom components, providing higher strength and rigidity compared to nylon sheets. Nylon sheets deliver flat, versatile material suitable for cutting, bending, and fabrication into larger surface areas, often used in applications requiring abrasion resistance and chemical stability. Selecting between nylon rods and sheets depends on the specific mechanical requirements and the manufacturing process involved.

Physical Properties: Rods vs Sheets

Nylon rods demonstrate superior tensile strength and impact resistance compared to nylon sheets, making them ideal for structural applications requiring durability and load-bearing capacity. Nylon sheets, however, offer greater flexibility and are easier to machine into custom shapes, suited for surface coverings and lightweight components. Both forms exhibit excellent chemical resistance and low friction, but rods typically provide better dimensional stability under mechanical stress.

Common Applications of Nylon Rods

Nylon rods are widely used in manufacturing bushings, spacers, and gears due to their high strength and excellent wear resistance, making them ideal for mechanical components subject to friction. These rods are commonly utilized in automotive, industrial machinery, and electrical insulation applications, where precision and durability are crucial. Nylon sheets, by contrast, are primarily chosen for surface protection, insulation panels, and cutting boards, highlighting the distinct advantages of nylon rods in load-bearing and moving parts.

Common Uses for Nylon Sheets

Nylon sheets are widely used in industrial applications such as machining components, structural supports, and wear-resistant surfaces due to their high strength and excellent abrasion resistance. They serve as an ideal material for cutting boards, electrical insulators, and mechanical parts requiring durability and chemical resistance. Unlike nylon rods, sheets offer a flat, uniform surface making them suitable for fabrication into complex shapes and large-scale panels.

Strength and Durability Comparison

Nylon rods exhibit higher tensile strength due to their dense molecular alignment, making them ideal for load-bearing applications. Nylon sheets, while slightly less strong, provide superior impact resistance and flexibility, enhancing durability in dynamic environments. Both forms offer excellent wear resistance, but rods typically outperform sheets in structural rigidity and long-term mechanical stability.

Machinability and Fabrication Differences

Nylon rods offer superior machinability compared to nylon sheets due to their uniform cross-section, allowing for precise turning, drilling, and milling operations with minimal tool wear. Nylon sheets require more extensive fabrication techniques such as cutting, shaping, and sometimes thermal forming, which can affect dimensional accuracy and surface finish. The choice between rods and sheets depends on the specific application requirements for strength, fabrication complexity, and tolerance precision.

Cost and Availability: Rods vs Sheets

Nylon rods generally have a higher cost per unit compared to nylon sheets due to their manufacturing process and specific applications. Nylon sheets are widely available in various thicknesses and sizes, making them more accessible and cost-effective for large surface area projects. Both materials are readily stocked by major suppliers, but sheets offer better value for bulk orders, while rods cater to precise, structural needs where durability and shape retention are critical.

Choosing the Right Nylon Material for Your Project

Nylon rods offer superior strength and dimensional stability, making them ideal for applications requiring precise machining and durability, such as gears and bushings. Nylon sheets provide a versatile flat surface suitable for cutting and forming into various shapes, often used in fabrication and prototyping tasks. Selecting between nylon rods and sheets depends on project requirements like mechanical stress, machining complexity, and component geometry to ensure optimal performance.

Conclusion: Nylon Rods vs Sheets – Which Is Better?

Nylon rods offer superior strength and wear resistance, making them ideal for mechanical parts and industrial applications requiring durability and precision. Nylon sheets provide greater versatility in fabrication, allowing easier cutting, shaping, and forming for custom projects and prototypes. Choosing between nylon rods and sheets depends on the specific application needs, with rods best for structural use and sheets preferred for flexible manufacturing.

Nylon rods vs Nylon sheets Infographic

materialdif.com

materialdif.com