Solution-dyed nylon offers superior colorfastness and resistance to fading compared to piece-dyed nylon, as the color is integrated into the fiber during the manufacturing process. Piece-dyed nylon undergoes dyeing after the fibers are spun, resulting in vibrant colors but lower durability and potential for uneven color retention. Choosing solution-dyed nylon ensures longer-lasting, fade-resistant fabrics ideal for high-performance and outdoor applications.

Table of Comparison

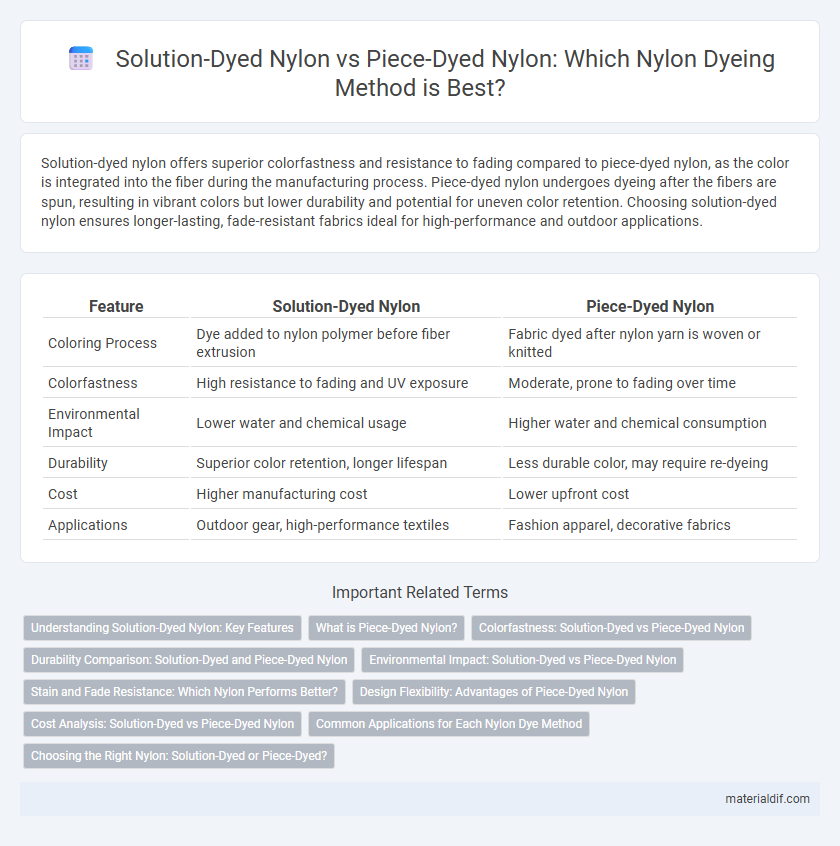

| Feature | Solution-Dyed Nylon | Piece-Dyed Nylon |

|---|---|---|

| Coloring Process | Dye added to nylon polymer before fiber extrusion | Fabric dyed after nylon yarn is woven or knitted |

| Colorfastness | High resistance to fading and UV exposure | Moderate, prone to fading over time |

| Environmental Impact | Lower water and chemical usage | Higher water and chemical consumption |

| Durability | Superior color retention, longer lifespan | Less durable color, may require re-dyeing |

| Cost | Higher manufacturing cost | Lower upfront cost |

| Applications | Outdoor gear, high-performance textiles | Fashion apparel, decorative fabrics |

Understanding Solution-Dyed Nylon: Key Features

Solution-dyed nylon is produced by adding color pigments directly into the nylon polymer before fiber extrusion, resulting in fibers with vibrant, long-lasting color that resists fading from sunlight and washing. This method enhances colorfastness and reduces environmental impact by minimizing water and chemical usage compared to traditional piece-dyeing processes. The inherent color stability and improved durability of solution-dyed nylon make it ideal for outdoor textiles, upholstery, and performance apparel.

What is Piece-Dyed Nylon?

Piece-dyed nylon refers to fabric that is dyed after the textile has been woven or knitted, allowing for a wide range of color customization and flexibility. This dyeing method involves immersing the fabric in dye baths, resulting in colors that penetrate the fibers from the outside, which can fade over time with exposure to sunlight and washing. Piece-dyed nylon is often chosen for fashion and home textiles where versatile coloring and softer fabric hand feel are priorities.

Colorfastness: Solution-Dyed vs Piece-Dyed Nylon

Solution-dyed nylon offers superior colorfastness as the color pigment is added during the polymer extrusion process, ensuring deep, uniform color that resists fading from sunlight, washing, and abrasion. Piece-dyed nylon involves dyeing the fabric after it is woven, resulting in less durable color that can fade more quickly due to surface-level dye penetration. This makes solution-dyed nylon the preferred choice for outdoor applications requiring long-lasting, vibrant color performance.

Durability Comparison: Solution-Dyed and Piece-Dyed Nylon

Solution-dyed nylon fibers demonstrate superior colorfastness and resistance to fading due to pigment infusion during fiber extrusion, enhancing long-term durability under UV exposure and repeated laundering. In contrast, piece-dyed nylon absorbs dye post-fabric formation, making it more prone to color loss and wear over time. The intrinsic pigmentation of solution-dyed nylon also improves resistance to chemical degradation, making it a preferred choice for high-performance and outdoor applications requiring sustained durability.

Environmental Impact: Solution-Dyed vs Piece-Dyed Nylon

Solution-dyed nylon significantly reduces water consumption by integrating color pigments into the polymer before fiber extrusion, eliminating the need for multiple dye baths required in piece-dyed processes. This method also minimizes chemical usage and wastewater generation, leading to a lower environmental footprint compared to traditional piece-dyed nylon, which relies heavily on water and synthetic dyes. Consequently, solution-dyed nylon offers a sustainable alternative that aligns with eco-friendly textile manufacturing standards.

Stain and Fade Resistance: Which Nylon Performs Better?

Solution-dyed nylon exhibits superior stain and fade resistance compared to piece-dyed nylon due to its color being integrated during the fiber extrusion process, ensuring long-lasting vibrancy and durability. In contrast, piece-dyed nylon involves dyeing fibers after they are woven or knitted, making the color more susceptible to fading and staining over time. This inherent difference in dyeing methods makes solution-dyed nylon the preferred choice for applications requiring enhanced colorfastness and resistance to environmental wear.

Design Flexibility: Advantages of Piece-Dyed Nylon

Piece-dyed nylon offers superior design flexibility by allowing fabric to be dyed after weaving, enabling a broader range of colors and custom shades that meet specific design requirements. This method supports intricate patterns and color variations that are difficult to achieve with solution-dyed nylon, which is limited to pre-colored fibers. Designers benefit from the ability to quickly adapt to trends and create unique textile aesthetics using piece-dyed nylon.

Cost Analysis: Solution-Dyed vs Piece-Dyed Nylon

Solution-dyed nylon incurs higher upfront costs due to the integration of color pigments during fiber extrusion, resulting in long-term savings from reduced water, energy, and dye usage compared to piece-dyed nylon, which involves post-fiber dyeing processes with lower initial costs but increased resource consumption and environmental impact. Piece-dyed nylon typically requires more labor and chemical treatments, contributing to variable production expenses and additional wastewater management costs. Evaluating total cost of ownership reveals solution-dyed nylon as more economical in large-scale, sustainable applications despite its higher initial investment.

Common Applications for Each Nylon Dye Method

Solution-dyed nylon is frequently used in outdoor gear, automotive fabrics, and marine applications due to its superior colorfastness and UV resistance, ensuring durability in harsh environments. Piece-dyed nylon is commonly applied in fashion textiles, upholstery, and hosiery where vibrant colors and a wide range of shades are essential. Both dye methods cater to distinct market needs, with solution-dyeing favored for performance and piece-dyeing for aesthetic versatility.

Choosing the Right Nylon: Solution-Dyed or Piece-Dyed?

Solution-dyed nylon offers superior colorfastness and resistance to fading due to its pigment integration during fiber formation, making it ideal for outdoor and high-exposure applications. Piece-dyed nylon allows for greater color customization post-fiber production but may show more wear and color loss over time. Choosing between solution-dyed and piece-dyed nylon depends on the specific requirements of durability, color consistency, and cost-effectiveness for your project.

Solution-Dyed Nylon vs Piece-Dyed Nylon Infographic

materialdif.com

materialdif.com