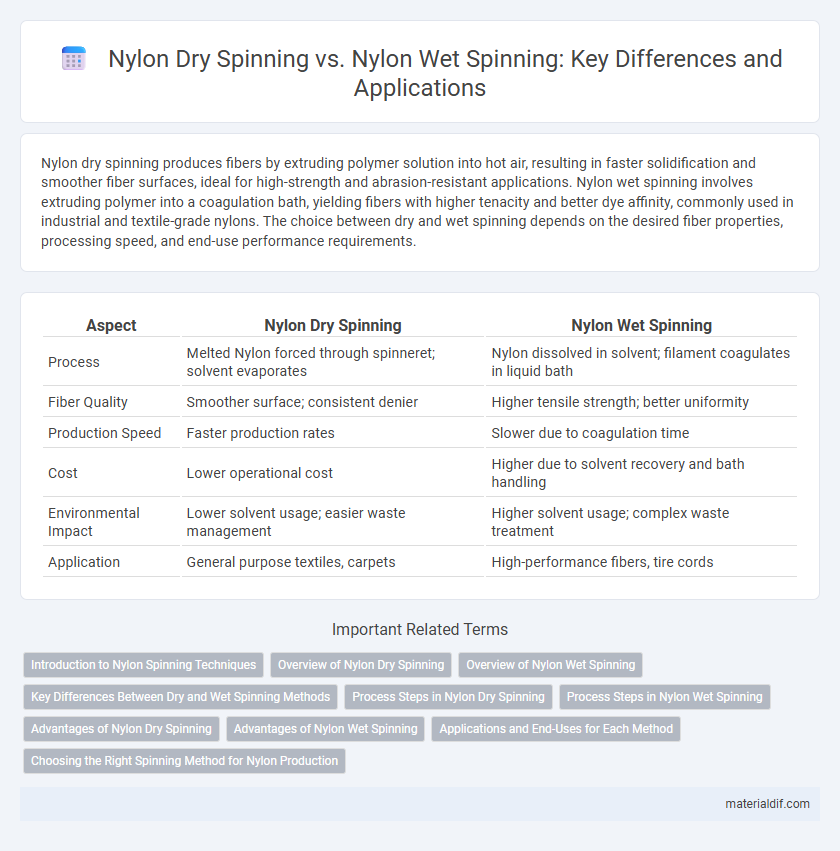

Nylon dry spinning produces fibers by extruding polymer solution into hot air, resulting in faster solidification and smoother fiber surfaces, ideal for high-strength and abrasion-resistant applications. Nylon wet spinning involves extruding polymer into a coagulation bath, yielding fibers with higher tenacity and better dye affinity, commonly used in industrial and textile-grade nylons. The choice between dry and wet spinning depends on the desired fiber properties, processing speed, and end-use performance requirements.

Table of Comparison

| Aspect | Nylon Dry Spinning | Nylon Wet Spinning |

|---|---|---|

| Process | Melted Nylon forced through spinneret; solvent evaporates | Nylon dissolved in solvent; filament coagulates in liquid bath |

| Fiber Quality | Smoother surface; consistent denier | Higher tensile strength; better uniformity |

| Production Speed | Faster production rates | Slower due to coagulation time |

| Cost | Lower operational cost | Higher due to solvent recovery and bath handling |

| Environmental Impact | Lower solvent usage; easier waste management | Higher solvent usage; complex waste treatment |

| Application | General purpose textiles, carpets | High-performance fibers, tire cords |

Introduction to Nylon Spinning Techniques

Nylon spinning involves two primary techniques: dry spinning and wet spinning, each impacting fiber properties and production efficiency. Dry spinning evaporates a solvent from the polymer solution using hot air, creating smooth, strong fibers ideal for textiles requiring high durability. Wet spinning extrudes the polymer into a coagulation bath, producing fibers with enhanced tensile strength and chemical resistance, suited for industrial applications.

Overview of Nylon Dry Spinning

Nylon dry spinning involves dissolving polyamide polymers in a volatile solvent and extruding the solution through fine spinnerets into a heated chamber, where the solvent evaporates to form solid fibers. This method allows precise control over fiber diameter and morphology, producing smooth, uniform filaments ideal for textiles and industrial applications. Compared to wet spinning, dry spinning offers faster production rates and lower energy consumption, making it economically advantageous for producing high-quality nylon fibers.

Overview of Nylon Wet Spinning

Nylon wet spinning involves extruding polymer solutions into a coagulation bath where fibers solidify through solvent exchange, yielding finer denier and superior tensile strength compared to dry spinning. This method is essential for producing high-quality Nylon filaments used in industrial applications requiring enhanced durability and elasticity. Wet spinning allows precise control over fiber morphology and enables the incorporation of additives for specialized performance characteristics.

Key Differences Between Dry and Wet Spinning Methods

Dry spinning of nylon involves dissolving the polymer in a volatile solvent and extruding it into warm air, where the solvent evaporates to form fibers, resulting in higher production speeds and finer filament control. Wet spinning requires extruding nylon into a coagulation bath, causing the polymer to precipitate and solidify, producing fibers with greater strength and uniformity but slower production rates. Key differences include solvent recovery processes, fiber properties, and equipment complexity, with dry spinning favored for lightweight applications and wet spinning preferred for stronger, more durable fibers.

Process Steps in Nylon Dry Spinning

Nylon dry spinning involves dissolving the polymer in a volatile solvent, then extruding the solution through spinnerets into a heated chamber where the solvent evaporates, solidifying the filaments. Key process steps include preparing the polymer solution, extrusion through fine holes, solvent evaporation in warm air, and filament winding onto bobbins. This method contrasts wet spinning by eliminating the coagulation bath, enabling faster production and producing fibers with distinct mechanical properties.

Process Steps in Nylon Wet Spinning

Nylon wet spinning involves dissolving the polymer in a suitable solvent before extrusion through spinnerets into a coagulation bath, where the fibers solidify by solvent exchange and precipitation. The process steps include polymer solution preparation, filtration to remove impurities, extrusion into the coagulation bath, washing to remove residual solvents, and drying the fibers. This method allows control over fiber properties such as strength and fineness by adjusting solution concentration, bath composition, and stretching conditions.

Advantages of Nylon Dry Spinning

Nylon dry spinning offers superior control over fiber diameter and produces fibers with smoother surfaces, enhancing fabric strength and durability. This method is more cost-effective as it requires less water and energy than wet spinning, making it environmentally friendly and suitable for large-scale production. Dry spinning also enables faster production rates and better filament uniformity, contributing to high-quality nylon textiles.

Advantages of Nylon Wet Spinning

Nylon wet spinning offers superior control over fiber morphology and higher tensile strength due to its ability to solidify fibers in a coagulation bath, resulting in enhanced uniformity and reduced defects. This process allows for better orientation of polymer chains, improving elasticity and durability compared to dry spinning. Wet spinning also supports spinning of higher molecular weight polymers, which contributes to stronger and more resilient nylon fibers ideal for demanding applications.

Applications and End-Uses for Each Method

Nylon dry spinning is predominantly used for producing fibers with high tensile strength and smooth surface textures, making it ideal for applications in apparel, industrial sewing threads, and carpet yarns. Nylon wet spinning produces fibers with superior elasticity and dye uptake, commonly employed in tire cords, military uniforms, and high-performance textiles. Each spinning method's unique fiber properties drive specific end-uses, optimizing performance and durability according to industry requirements.

Choosing the Right Spinning Method for Nylon Production

Nylon dry spinning efficiently produces strong, lightweight fibers by extruding polymer solutions with solvent evaporation, ideal for high-speed manufacturing and consistent fiber quality. In contrast, nylon wet spinning immerses the polymer solution in a coagulation bath, enabling better control over fiber properties like tenacity and elongation, which suits applications requiring enhanced mechanical performance. Selecting the appropriate spinning method depends on desired fiber characteristics, production scale, and end-use requirements in nylon textile manufacturing.

Nylon dry spinning vs Nylon wet spinning Infographic

materialdif.com

materialdif.com