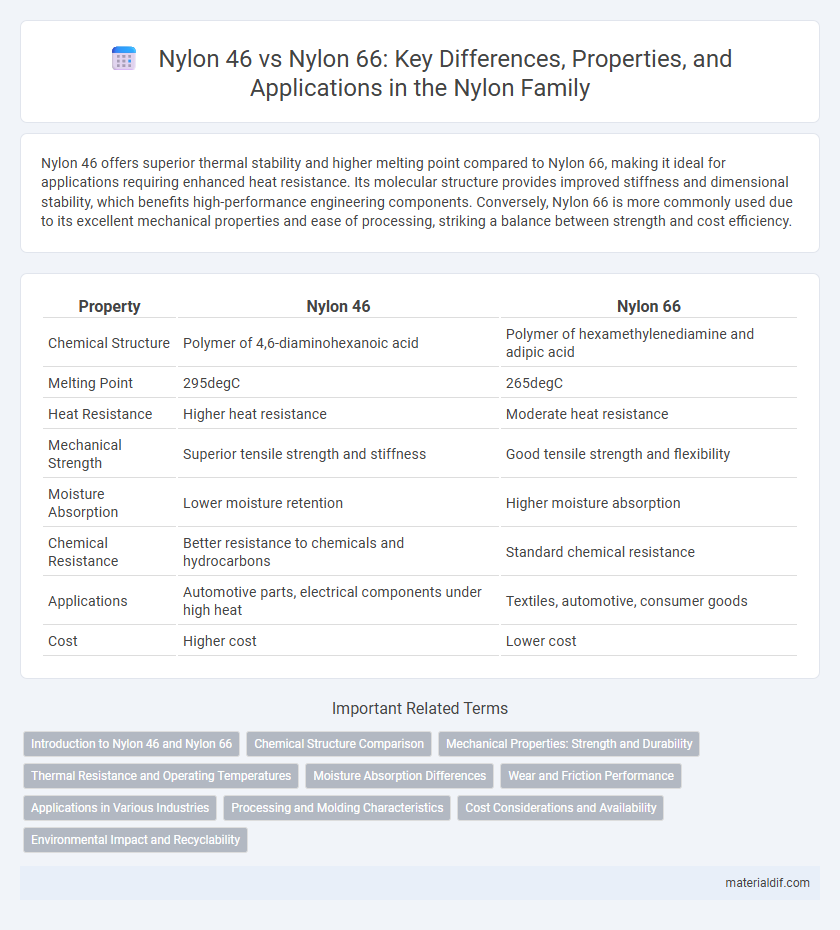

Nylon 46 offers superior thermal stability and higher melting point compared to Nylon 66, making it ideal for applications requiring enhanced heat resistance. Its molecular structure provides improved stiffness and dimensional stability, which benefits high-performance engineering components. Conversely, Nylon 66 is more commonly used due to its excellent mechanical properties and ease of processing, striking a balance between strength and cost efficiency.

Table of Comparison

| Property | Nylon 46 | Nylon 66 |

|---|---|---|

| Chemical Structure | Polymer of 4,6-diaminohexanoic acid | Polymer of hexamethylenediamine and adipic acid |

| Melting Point | 295degC | 265degC |

| Heat Resistance | Higher heat resistance | Moderate heat resistance |

| Mechanical Strength | Superior tensile strength and stiffness | Good tensile strength and flexibility |

| Moisture Absorption | Lower moisture retention | Higher moisture absorption |

| Chemical Resistance | Better resistance to chemicals and hydrocarbons | Standard chemical resistance |

| Applications | Automotive parts, electrical components under high heat | Textiles, automotive, consumer goods |

| Cost | Higher cost | Lower cost |

Introduction to Nylon 46 and Nylon 66

Nylon 46 and Nylon 66 are both polyamides used extensively in engineering plastics, with Nylon 46 known for its superior thermal stability and higher melting point of approximately 295degC compared to Nylon 66's melting point of around 260degC. Nylon 46 exhibits enhanced mechanical strength and dimensional stability at elevated temperatures, making it suitable for high-performance automotive and electrical applications. Nylon 66, with its balanced toughness, chemical resistance, and ease of processing, remains widely utilized in consumer goods, textiles, and industrial components.

Chemical Structure Comparison

Nylon 46 features a polymer chain composed of hexamethylene diamine and adipic acid, resulting in a higher melting point due to its shorter molecular repeat units and increased hydrogen bonding. In contrast, Nylon 66 consists of hexamethylene diamine and hexanedioic acid, offering greater flexibility but lower thermal resistance compared to Nylon 46. The distinct amide linkages and chain alignment in Nylon 46 contribute to its superior dimensional stability and mechanical strength over Nylon 66.

Mechanical Properties: Strength and Durability

Nylon 46 exhibits superior mechanical strength and thermal resistance compared to Nylon 66, making it ideal for high-performance engineering applications. Its higher melting point of approximately 295degC contributes to enhanced durability under elevated temperatures, while Nylon 66 typically melts around 265degC. The increased crystallinity of Nylon 46 results in improved tensile strength and wear resistance, outperforming Nylon 66 in demanding environments requiring long-lasting material performance.

Thermal Resistance and Operating Temperatures

Nylon 46 exhibits superior thermal resistance compared to Nylon 66, with a higher melting point around 295degC versus 260degC for Nylon 66. This enhanced thermal stability allows Nylon 46 to operate effectively in continuous use temperatures up to approximately 180degC, while Nylon 66 is generally limited to around 120degC to 140degC. The improved heat resistance of Nylon 46 makes it ideal for applications demanding high-temperature durability and prolonged thermal exposure.

Moisture Absorption Differences

Nylon 46 exhibits significantly lower moisture absorption compared to Nylon 66 due to its higher crystallinity and tighter molecular structure, which reduces water molecule penetration. This characteristic enhances Nylon 46's dimensional stability and mechanical properties in humid environments. Consequently, Nylon 46 is preferred for applications requiring minimal moisture-induced performance degradation.

Wear and Friction Performance

Nylon 46 exhibits superior wear resistance and lower friction coefficients compared to Nylon 66 due to its higher melting point and increased crystallinity, which enhance dimensional stability under mechanical stress. The molecular structure of Nylon 46 contributes to improved load-bearing capacity and reduced surface degradation in high-friction applications. These properties make Nylon 46 more suitable for demanding environments such as automotive components and industrial gears where durability and extended service life are critical.

Applications in Various Industries

Nylon 46 exhibits superior thermal stability and mechanical strength, making it ideal for high-performance automotive components and electrical connectors requiring heat resistance. Nylon 66 is widely used in textiles, industrial machinery parts, and consumer goods due to its excellent abrasion resistance and chemical durability. Both types play crucial roles in manufacturing sectors, with Nylon 46 preferred in aerospace and high-temperature environments, while Nylon 66 dominates in general-purpose applications.

Processing and Molding Characteristics

Nylon 46 exhibits higher melting temperature and superior thermal stability compared to Nylon 66, allowing for processing at elevated temperatures without degradation. Its enhanced crystallinity results in faster crystallization rates during molding, reducing cycle times and improving dimensional stability. Nylon 66, while easier to process at lower temperatures, may experience longer cooling times and slightly lower mechanical performance under high-heat applications.

Cost Considerations and Availability

Nylon 46 typically incurs higher costs due to its complex manufacturing process and limited production scale compared to Nylon 66, which benefits from established mass production and widespread availability. Nylon 66 is generally more cost-effective and readily accessible for industries requiring bulk polymer supply. The price and supply advantages of Nylon 66 make it the preferred choice in cost-sensitive applications despite Nylon 46's superior thermal properties.

Environmental Impact and Recyclability

Nylon 46 offers superior thermal stability and mechanical strength compared to Nylon 66, enabling longer product lifespans and reducing frequent replacements, which lowers overall environmental impact. Nylon 46's crystallinity also facilitates more efficient recycling processes, resulting in higher-quality recycled materials with less degradation than Nylon 66. Both nylons are recyclable, but Nylon 46's enhanced recyclability and durability contribute to improved sustainability in industrial applications.

Nylon 46 vs Nylon 66 Infographic

materialdif.com

materialdif.com