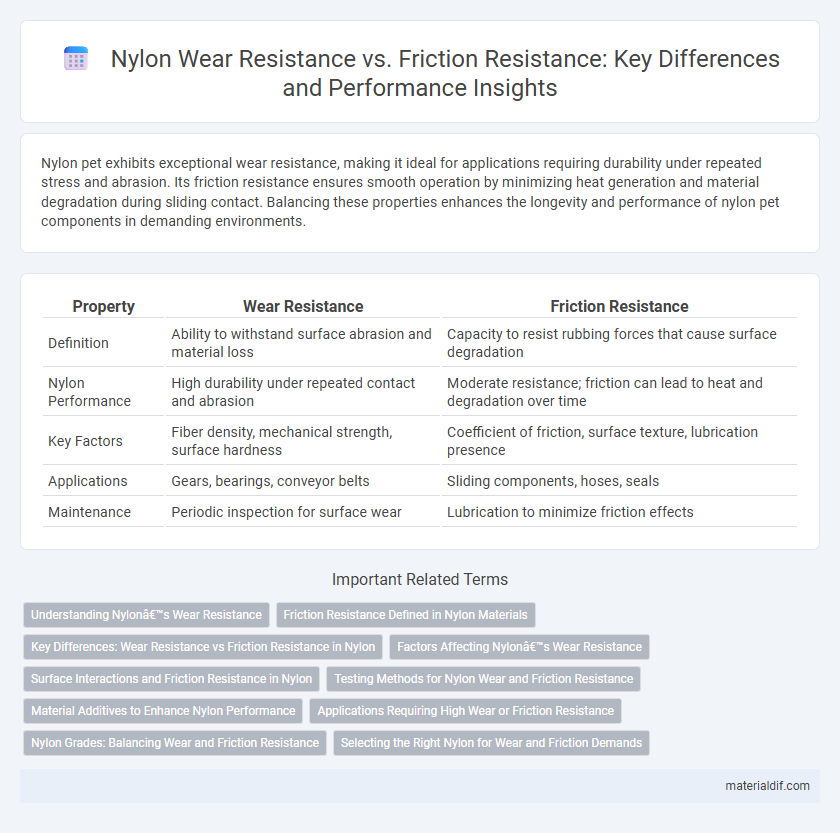

Nylon pet exhibits exceptional wear resistance, making it ideal for applications requiring durability under repeated stress and abrasion. Its friction resistance ensures smooth operation by minimizing heat generation and material degradation during sliding contact. Balancing these properties enhances the longevity and performance of nylon pet components in demanding environments.

Table of Comparison

| Property | Wear Resistance | Friction Resistance |

|---|---|---|

| Definition | Ability to withstand surface abrasion and material loss | Capacity to resist rubbing forces that cause surface degradation |

| Nylon Performance | High durability under repeated contact and abrasion | Moderate resistance; friction can lead to heat and degradation over time |

| Key Factors | Fiber density, mechanical strength, surface hardness | Coefficient of friction, surface texture, lubrication presence |

| Applications | Gears, bearings, conveyor belts | Sliding components, hoses, seals |

| Maintenance | Periodic inspection for surface wear | Lubrication to minimize friction effects |

Understanding Nylon’s Wear Resistance

Nylon exhibits excellent wear resistance due to its high tensile strength and resilience under repeated stress, making it ideal for applications involving continuous friction. Its molecular structure allows it to absorb impact energy and resist abrasion, outperforming many other polymers in durability. Understanding nylon's wear resistance is crucial for selecting materials in high-friction environments like gears, bearings, and conveyor belts, where longevity and performance are critical.

Friction Resistance Defined in Nylon Materials

Friction resistance in nylon materials refers to the ability of the polymer to withstand surface wear caused by sliding contact or rubbing with other materials. This property is critical in applications where nylon components experience repeated motion, such as gears, bearings, and conveyor belts, helping to reduce surface degradation and extend service life. The inherent molecular structure of nylon, with its strong intermolecular hydrogen bonding, contributes to its relatively high friction resistance compared to other synthetic polymers.

Key Differences: Wear Resistance vs Friction Resistance in Nylon

Nylon exhibits excellent wear resistance, which refers to its ability to withstand surface damage from repeated mechanical action, making it ideal for applications involving continuous abrasion. Friction resistance in Nylon, on the other hand, describes the material's capacity to resist sliding and reduce heat generation between contacting surfaces, enhancing its performance in moving parts such as gears and bearings. The key difference lies in wear resistance focusing on material durability over time, while friction resistance emphasizes minimizing heat and frictional force during operation.

Factors Affecting Nylon’s Wear Resistance

Nylon's wear resistance is significantly influenced by factors such as molecular structure, crystallinity, and moisture absorption. Higher crystallinity enhances abrasion resistance by increasing the polymer's hardness and reducing deformation under frictional forces. Moisture acts as a plasticizer, reducing wear resistance by lowering the tensile strength and increasing the material's susceptibility to frictional damage.

Surface Interactions and Friction Resistance in Nylon

Nylon exhibits excellent wear resistance due to its ability to form a durable, low-friction surface film during sliding interactions, which reduces material degradation. The polymer's molecular structure allows for effective energy dissipation at contact points, minimizing surface damage under repetitive frictional forces. Enhanced friction resistance in nylon results from its balanced surface energy and polymer chain mobility, enabling smooth movement against various counterparts and prolonging component lifespan.

Testing Methods for Nylon Wear and Friction Resistance

Testing methods for nylon wear and friction resistance commonly include pin-on-disk, block-on-ring, and reciprocating wear tests to simulate real-world abrasion and sliding conditions. Instrumented tribometers measure coefficient of friction and wear rate under controlled loads, speeds, and environmental settings to assess material performance. These standardized tests provide critical data on nylon's durability and frictional behavior, guiding applications in automotive, textile, and industrial components.

Material Additives to Enhance Nylon Performance

Material additives such as glass fibers and carbon black significantly enhance nylon's wear resistance by increasing hardness and reducing surface abrasion. Incorporating lubricants like PTFE or molybdenum disulfide lowers nylon's friction resistance, improving sliding performance and reducing heat generation during operation. Optimizing the type and concentration of these additives tailors nylon composites for demanding applications in automotive, industrial machinery, and consumer goods where durability and low friction are critical.

Applications Requiring High Wear or Friction Resistance

Nylon demonstrates exceptional wear resistance, making it ideal for applications such as gears, bearings, and conveyor belts where durability under continuous friction is critical. Its friction resistance varies with formulation and can be enhanced with additives like graphite or molybdenum disulfide to reduce surface wear and extend component lifespan. These properties position nylon as a preferred material in automotive parts, industrial machinery, and textiles requiring high abrasion and friction resistance.

Nylon Grades: Balancing Wear and Friction Resistance

Nylon grades such as Nylon 6, Nylon 6/6, and glass-filled variants offer distinct balances between wear resistance and friction resistance, critical for high-performance applications. Nylon 6/6 typically exhibits superior wear resistance due to higher crystallinity, while glass-filled nylon enhances dimensional stability and reduces friction under load. Selecting the appropriate nylon grade depends on the operational environment, where optimizing the trade-off between low friction and high wear resistance ensures durability and efficiency in mechanical components.

Selecting the Right Nylon for Wear and Friction Demands

Nylon's wear resistance is largely influenced by its molecular weight and crystallinity, making high-density Nylon variants ideal for abrasion-heavy applications. Friction resistance depends on the surface texture and additives like PTFE, which reduce coefficient of friction to enhance performance in sliding environments. Selecting the right Nylon requires balancing wear resistance with friction properties based on the specific operational stress and motion type in the application.

Nylon Wear Resistance vs Friction Resistance Infographic

materialdif.com

materialdif.com