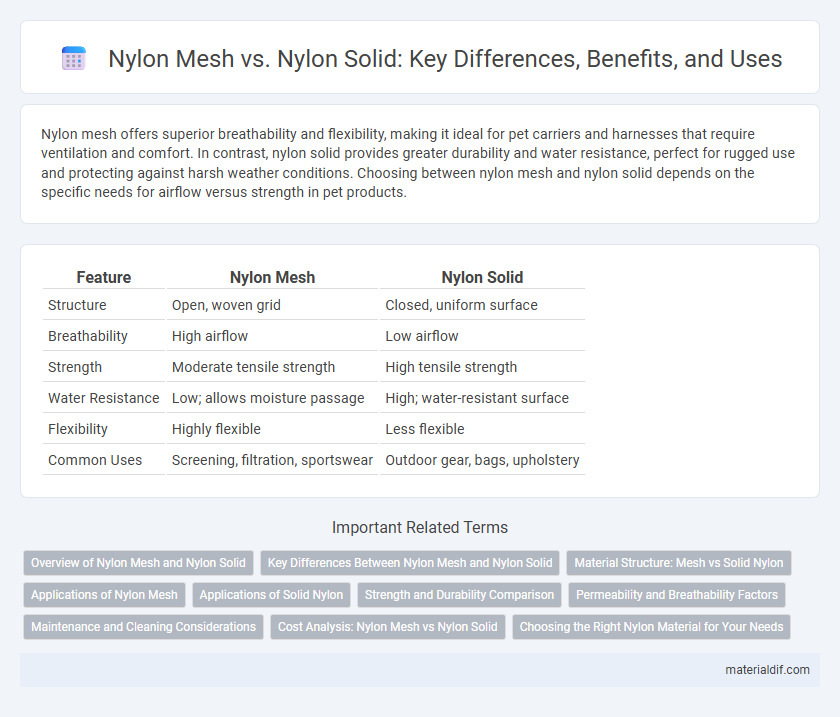

Nylon mesh offers superior breathability and flexibility, making it ideal for pet carriers and harnesses that require ventilation and comfort. In contrast, nylon solid provides greater durability and water resistance, perfect for rugged use and protecting against harsh weather conditions. Choosing between nylon mesh and nylon solid depends on the specific needs for airflow versus strength in pet products.

Table of Comparison

| Feature | Nylon Mesh | Nylon Solid |

|---|---|---|

| Structure | Open, woven grid | Closed, uniform surface |

| Breathability | High airflow | Low airflow |

| Strength | Moderate tensile strength | High tensile strength |

| Water Resistance | Low; allows moisture passage | High; water-resistant surface |

| Flexibility | Highly flexible | Less flexible |

| Common Uses | Screening, filtration, sportswear | Outdoor gear, bags, upholstery |

Overview of Nylon Mesh and Nylon Solid

Nylon mesh features an open-weave structure that allows for excellent breathability, filtration, and drainage, making it ideal for applications such as screens, sportswear, and industrial filters. Nylon solid, on the other hand, offers a dense, non-porous surface known for its strength, durability, and resistance to abrasion, commonly used in manufacturing components, molded parts, and protective gear. Both materials leverage nylon's inherent lightweight, flexibility, and chemical resistance but serve distinctly different functional needs based on their structural design.

Key Differences Between Nylon Mesh and Nylon Solid

Nylon mesh features an open-weave structure that allows for superior breathability and drainage, making it ideal for applications requiring ventilation or filtration. Nylon solid is characterized by a tightly woven, non-perforated fabric that provides enhanced durability, water resistance, and surface protection. Key differences include breathability, flexibility, and protective capabilities, with mesh offering air flow and solid emphasizing strength and barrier properties.

Material Structure: Mesh vs Solid Nylon

Nylon mesh consists of interwoven fibers creating an open, breathable structure ideal for filtration and ventilation applications, while solid nylon features a dense, continuous surface offering superior strength and resistance to abrasion. The porous nature of nylon mesh provides flexibility and lighter weight, enhancing airflow and moisture management. Solid nylon's compact molecular arrangement ensures durability and impact resistance, making it suitable for robust protective gear and industrial components.

Applications of Nylon Mesh

Nylon mesh is widely used in filtration, screening, and protective gear due to its breathable and flexible structure, allowing efficient airflow and particle separation. Industries such as agriculture, food processing, and construction utilize nylon mesh for sieving, insect screens, and reinforcement materials. Compared to nylon solid, nylon mesh offers superior versatility in applications requiring ventilation, drainage, and lightweight support.

Applications of Solid Nylon

Solid nylon offers superior strength and durability compared to nylon mesh, making it ideal for applications requiring heavy-duty performance such as gears, bearings, and wear-resistant components in automotive and industrial machinery. Its solid structure provides excellent impact resistance and low friction, which enhances mechanical efficiency and longevity in precision parts. Solid nylon is commonly used in electrical insulation parts, structural components, and consumer goods where rigidity and robustness are critical.

Strength and Durability Comparison

Nylon mesh offers high tensile strength while allowing flexibility and breathability, making it ideal for applications requiring ventilation and lighter weight. Nylon solid provides superior durability and impact resistance due to its dense structure, suitable for heavy-duty uses where maximum protection is essential. Both materials exhibit excellent abrasion resistance, but nylon solid outperforms mesh in load-bearing capacity and long-term wear under harsh conditions.

Permeability and Breathability Factors

Nylon mesh offers superior permeability and breathability compared to nylon solid due to its open weave structure, allowing better air flow and moisture vapor transmission. This enhanced ventilation makes nylon mesh ideal for applications requiring cooling and quick drying, such as athletic wear and outdoor gear. In contrast, nylon solid provides less breathability but offers higher water resistance and durability for protective or insulating uses.

Maintenance and Cleaning Considerations

Nylon mesh offers superior breathability and quick drying, making it easier to clean and maintain without retaining dirt or moisture compared to nylon solid. Nylon solid surfaces are more resistant to stains and can be wiped clean efficiently but may trap more heat and odors, requiring occasional deeper cleaning. Both materials tolerate mild detergent and water cleaning, but nylon mesh benefits from gentle brushing to remove embedded particles.

Cost Analysis: Nylon Mesh vs Nylon Solid

Nylon mesh typically costs less than nylon solid due to its reduced material usage and lighter weight, making it an economical choice for applications requiring breathability and flexibility. Nylon solid, while more expensive, offers superior durability and strength, justifying the higher price in heavy-duty or high-impact environments. Cost analysis should consider long-term performance and maintenance expenses, as nylon solid often outperforms nylon mesh in wear resistance and lifespan.

Choosing the Right Nylon Material for Your Needs

Nylon mesh offers excellent breathability and flexibility, making it ideal for applications requiring ventilation and lightweight strength, such as sports gear and outdoor equipment. Nylon solid provides superior durability, abrasion resistance, and waterproof qualities, suited for heavy-duty uses like luggage, upholstery, and protective clothing. Selecting the right nylon material depends on your specific needs for airflow, durability, and environmental exposure.

Nylon Mesh vs Nylon Solid Infographic

materialdif.com

materialdif.com